A low-loss temperature-pressure composite sensor air nozzle

A composite sensor, low-loss technology, applied in the field of sensors, can solve problems such as single parameter measurement, and achieve the effect of ensuring identity, ensuring sealing, and reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

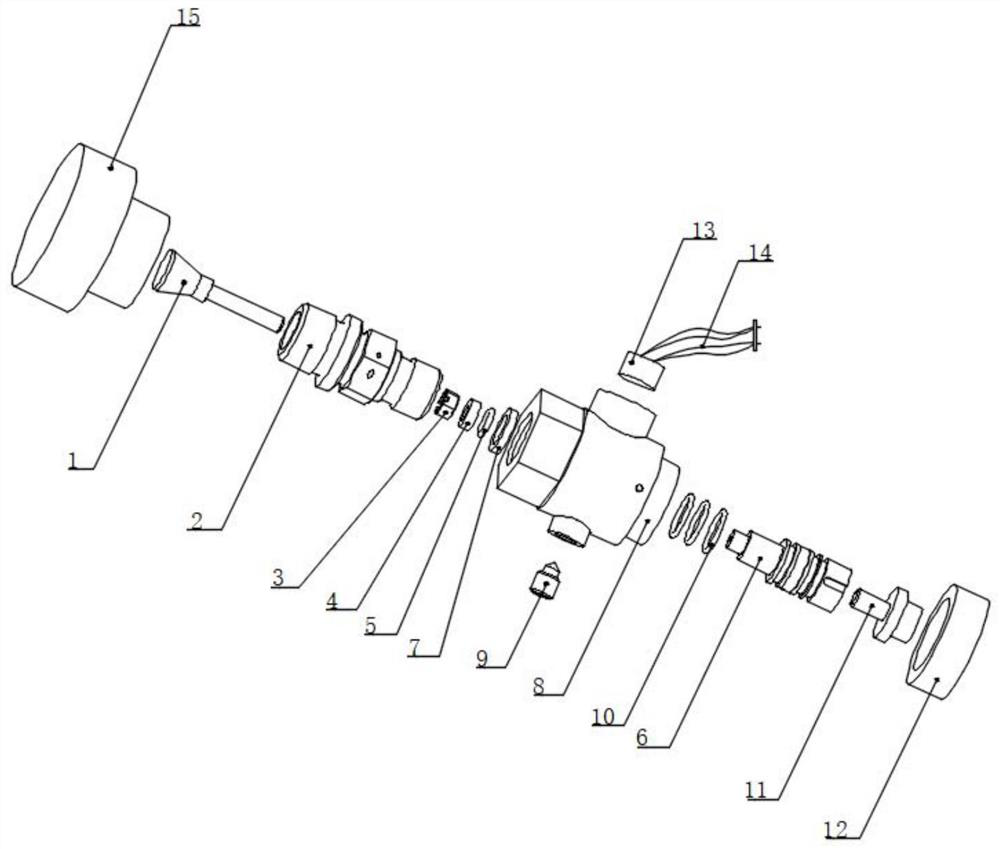

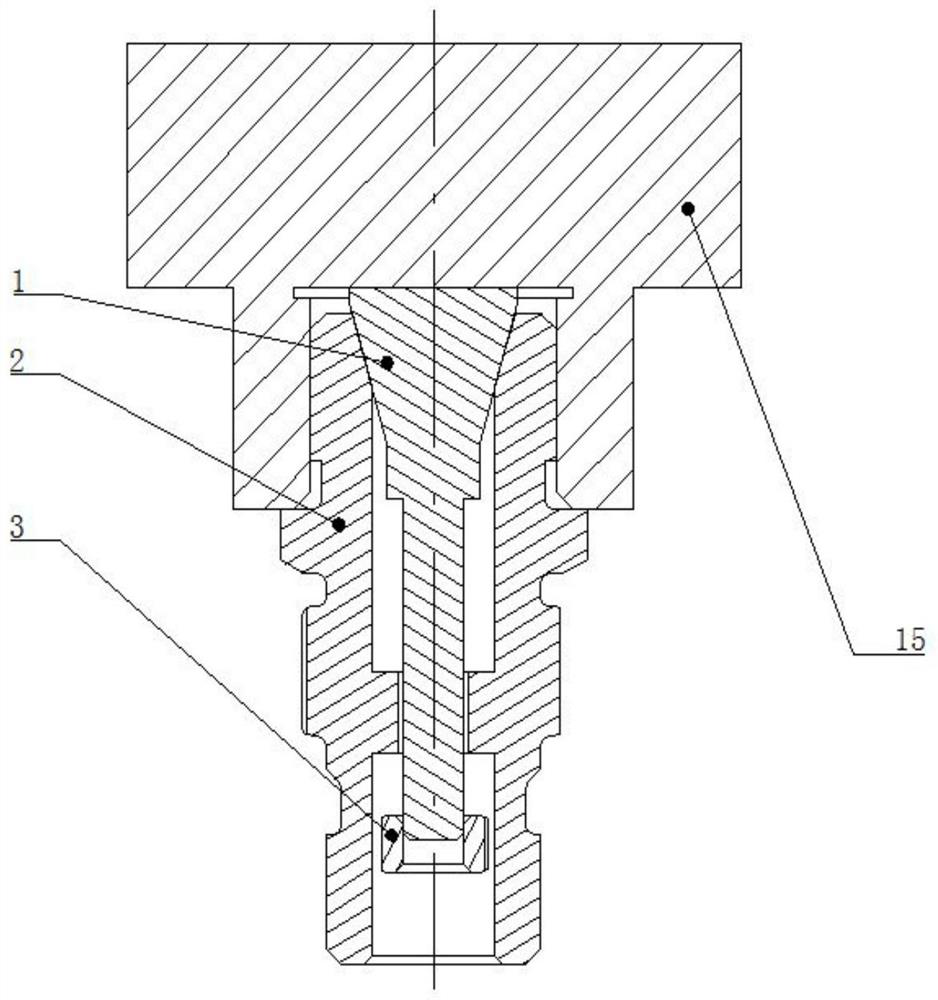

[0037] like Figure 1-6 As shown in the figure, a low-loss temperature and pressure composite sensor air nozzle includes a one-way valve core 1, a one-way valve body 2, a control valve core 6, a control valve body 8, a temperature and pressure sensing core 13, and bolts 11;

[0038] One end of the one-way valve body 2 is connected to one end of the control valve body 8 , and the internal passage of the one-way valve body 2 communicates with the internal passage of the control valve body 8 ;

[0039] The one-way valve spool 1 is located in the inner passage of the one-way valve body 2, the control valve spool 6 is located in the inner passage of the control valve body 8, and the control valve spool 6 The internal passage communicates with the internal passage of the one-way valve spool 1;

[0040] The temperature and pressure sensing core 13 is located in the installation groove of the control valve body 8; the temperature and pressure sensing core 13 collects the temperature...

Embodiment 2

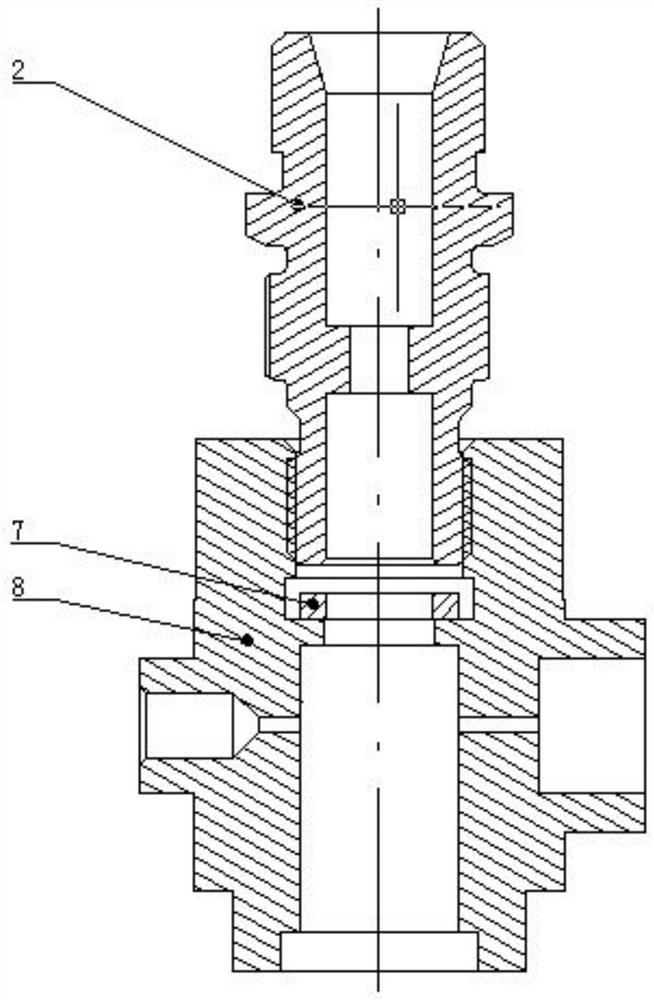

[0061] In this embodiment, on the basis of Embodiment 1, an air release valve 9 is provided on the outside of the control valve body 8 , and the air release valve 9 is screwed to the control valve body 8 .

[0062] The function of the air release valve 9 is to discharge the residual gas in the inner cavity before or after the test, so as to prevent interference with the test test, and the installation position of the air release valve 9 is opposite to the installation position of the voltage stabilization induction core 13 .

[0063] The specific connection relationship between the air release valve 9 and the control valve body 8 is as follows: the air release valve 9 is installed to the control valve body through a threaded connection, and in the working state, the front end cone surface of the air release valve 9 corresponds to the position of the control valve body 8 The cone surface of the inner hole forms a sealing effect. There is a small gap at the connection position b...

Embodiment 3

[0065] This embodiment is further preferred on the basis of the above-mentioned embodiment, the temperature and pressure sensing core 13 is connected to the signal line 14;

[0066] The signal line 14 is used to output the temperature and pressure data of the measured gas detected by the temperature and pressure sensing core 13 . The temperature and pressure sensing core 13 can be a temperature and pressure sensor, or other temperature and pressure detection devices with equivalent functions.

[0067] The temperature and pressure sensing core 13 collects the temperature and pressure values in the test system or the test end, and outputs the collected temperature and pressure values as digital signals through the signal line 14, so as to achieve the purpose of real-time monitoring of test system parameters.

[0068] Regarding the low-loss temperature-pressure composite sensor air nozzle described in Embodiments 1-3, the specific installation method is:

[0069] (1) Select ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com