Gear set meshing detection transmission device for intelligent production of electromechanical valve of gas meter

A transmission device and gear set technology, which is applied in the field of gear set meshing detection transmission device, can solve problems such as damage, failure to avoid detection errors, and inability to ensure gear meshing, etc., to achieve the effect of ensuring detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings. As a limitation of the present invention.

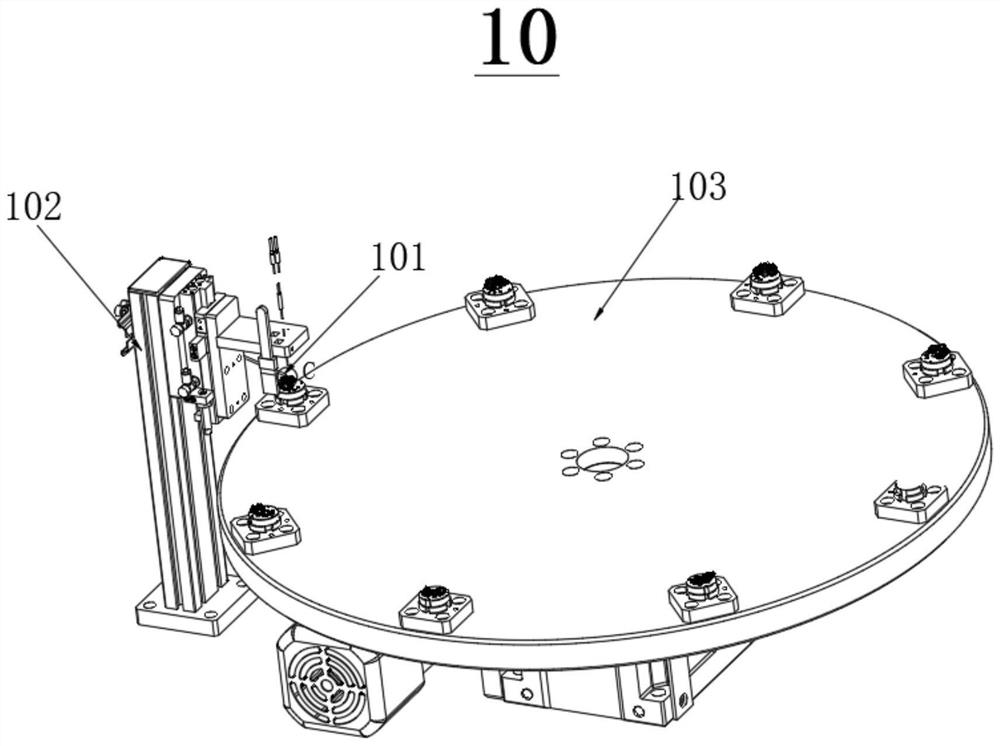

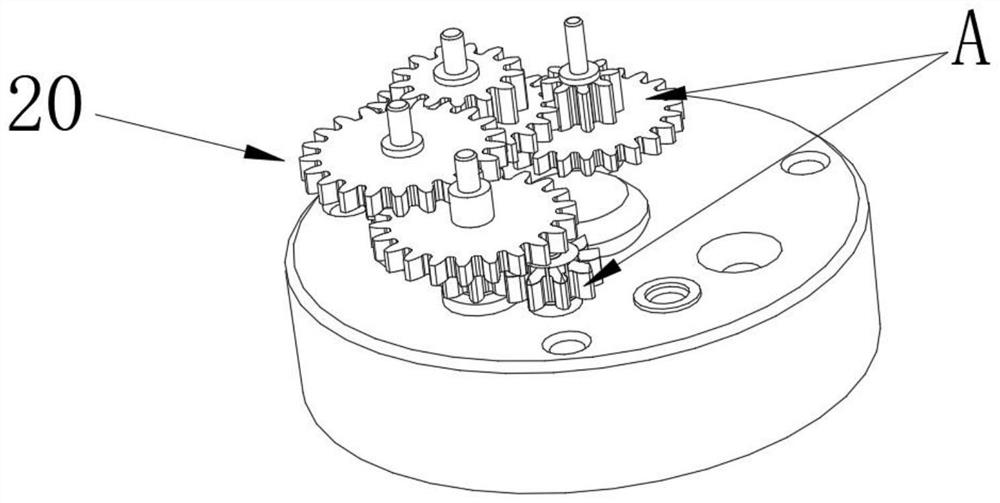

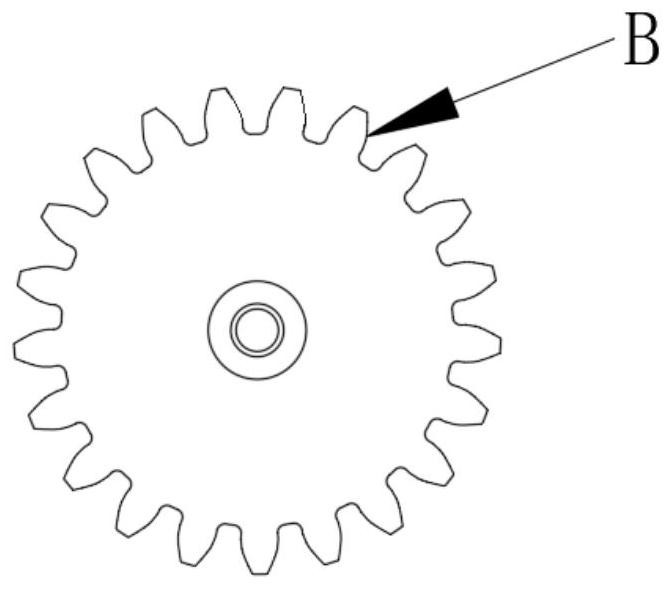

[0030] like figure 1 , figure 2 and image 3 As shown, this embodiment mainly discloses a gear set meshing detection transmission device 10 for intelligent production of gas meter electromechanical valves, which is provided with at least one air blowing part 101, and the air blowing part 101 is used for blowing air to drive through the gas flow. The internal gears of the transmission gear set 20 are meshed and driven; the blowing direction of the air blowing part 101 is directed to the inner tooth surface B of the tooth groove of the first stage or the final stage gear A in the transmission gear set.

[0031] In this embodiment, the air blowing part 101 is used as the power structure of the gear transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com