Asphalt concrete quality monitoring method and equipment thereof

A technology for asphalt concrete and quality monitoring, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as monitoring, lack of asphalt concrete quality, and affecting the timeliness of asphalt concrete, and achieve the effect of ensuring screening efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

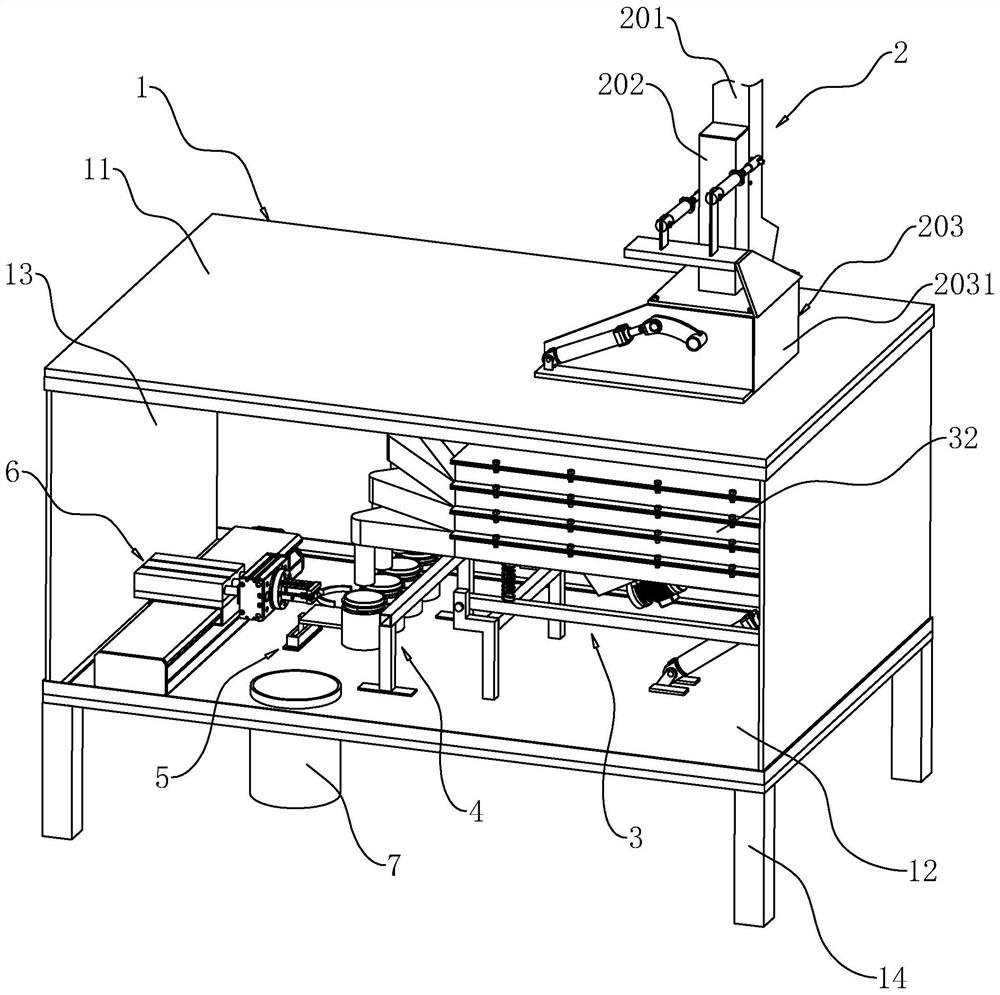

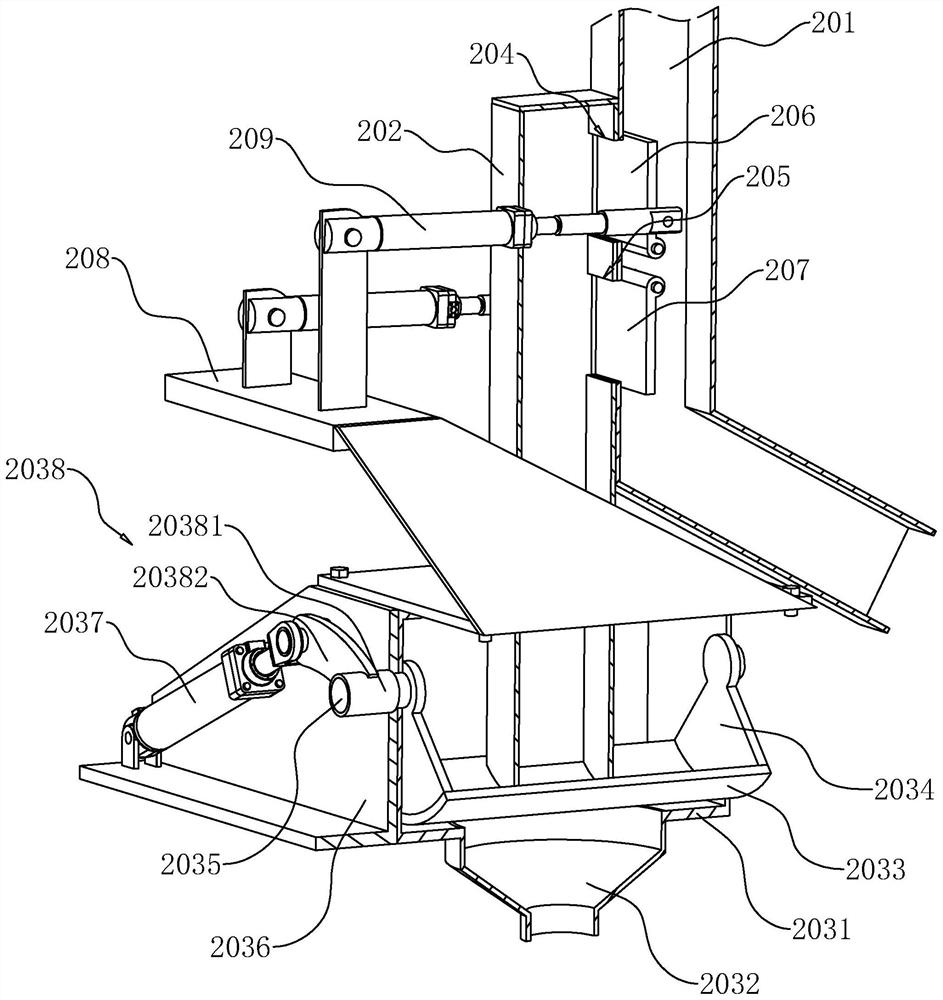

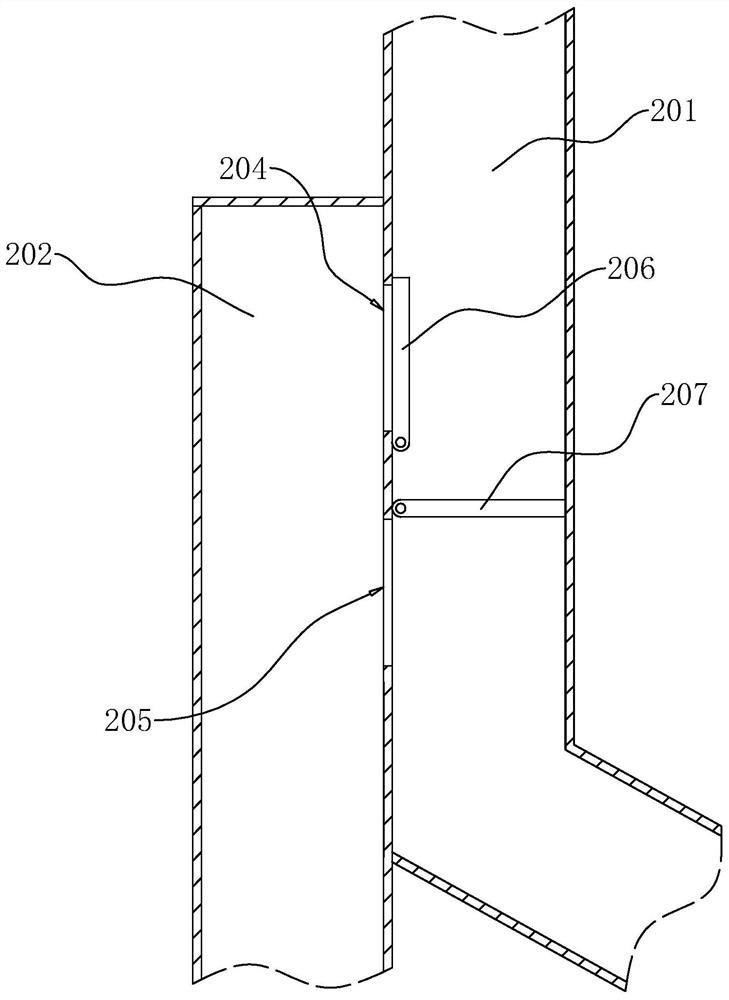

[0052] The application will be described in further detail below in conjunction with the accompanying drawings.

[0053] Production process of asphalt concrete:

[0054] Step 1: Drying and heating cold aggregate

[0055] The cold aggregate in the silo is transported to the drying drum by the belt conveyor, and the drying drum dries the cold aggregate and heats the cold aggregate to an appropriate temperature to make it into hot aggregate.

[0056] Step 2: Sieving Hot Aggregate

[0057] The hot aggregate is conveyed to the screening machine, so that the hot aggregate is screened into coarse grain (below 25-40 mm), medium grain (below 15-25 mm), fine grain (7-15 mm), sand grain (7 mm the following).

[0058] Step 3: Pack hot aggregate

[0059] The coarse grain, medium grain, fine grain and sand grain are divided into different thermal hoppers.

[0060] Step 4: Measuring Hot Aggregate

[0061] Coarse grain, medium grain, fine grain and sand grain flow into different weighin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com