Frictional force prediction and compensation method of feeding system and computer readable storage medium

A technology of feed system and compensation method, which is applied in the general control system, control/adjustment system, test/monitoring control system, etc., can solve the problems affecting the processing quality and precision of the feed system, and achieve the improvement of processing quality and precision. degree, to overcome the effect of lack of motivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

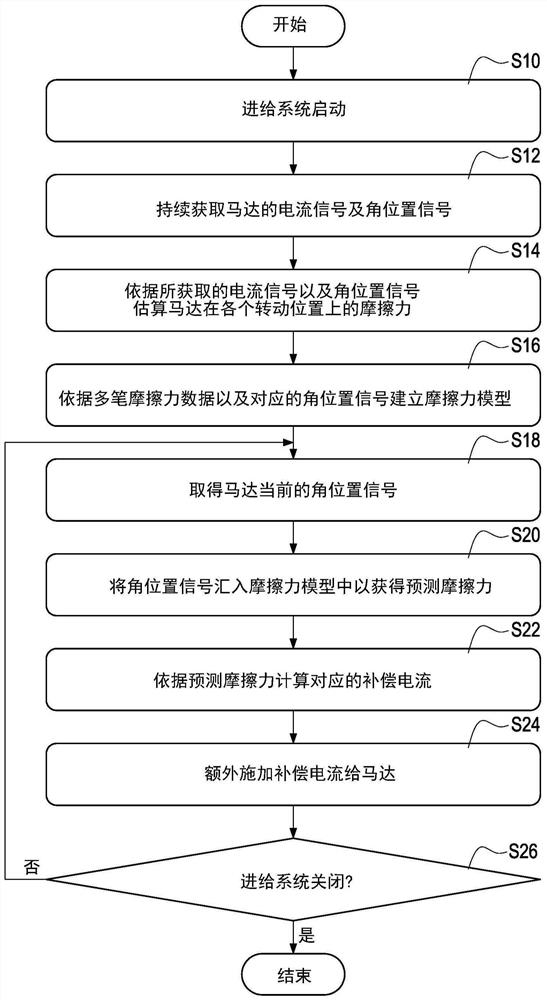

[0046] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

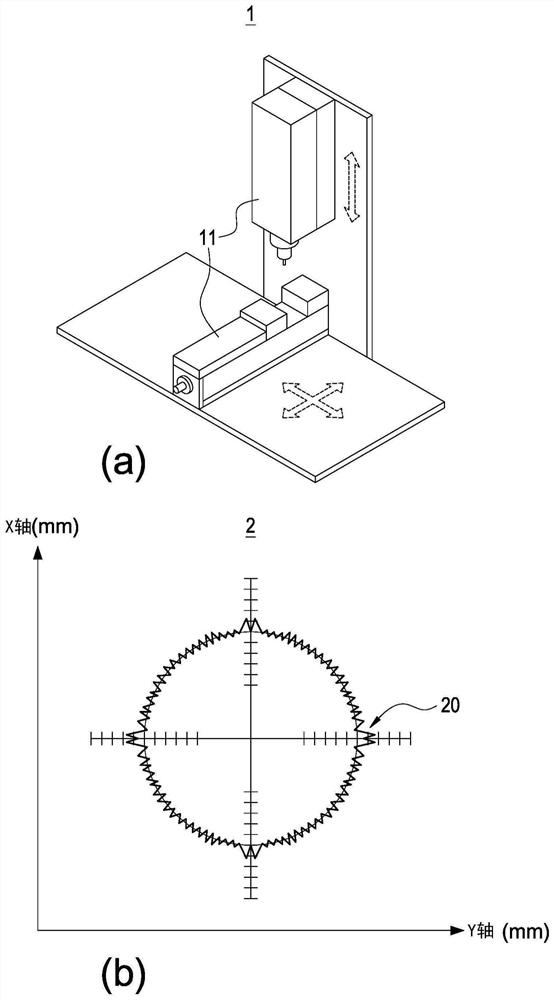

[0047] The invention discloses a method for predicting and compensating the friction force of a feed system, which is mainly used to predict the friction force of the feed system during operation, and timely compensate the motor inside the feed system, so as to avoid The power is not enough to overcome the friction of the feed system and affect the processing quality and precision provided.

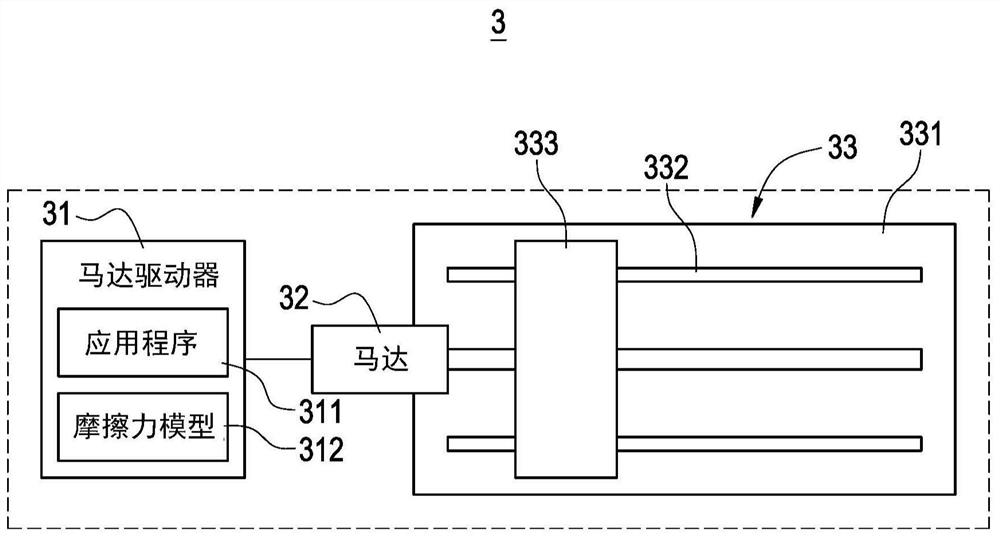

[0048] See first figure 2 , is the first specific embodiment of the block diagram of the feeding system of the present invention. The friction prediction and compensation method of the present invention (hereinafter referred to as the compensation method for short in the specification) is mainly applied to such as figure 2 The feeding system 3 is shown. At figure 2 In the embodiment, the feeding system 3 mainly includes a motor driver 31, a motor 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com