Liquid sulfur storage tank fire alarm device and liquid sulfur storage tank

The technology of liquid sulfur storage tank and sulfur storage tank is applied in the direction of electric fire alarm, packaging, transportation and packaging, etc., which can solve the problems of inconvenient maintenance of temperature sensors, difficult installation of temperature sensors, consumption of temperature sensors, etc. To achieve the effect of easy maintenance and operation, simple and novel structure, and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

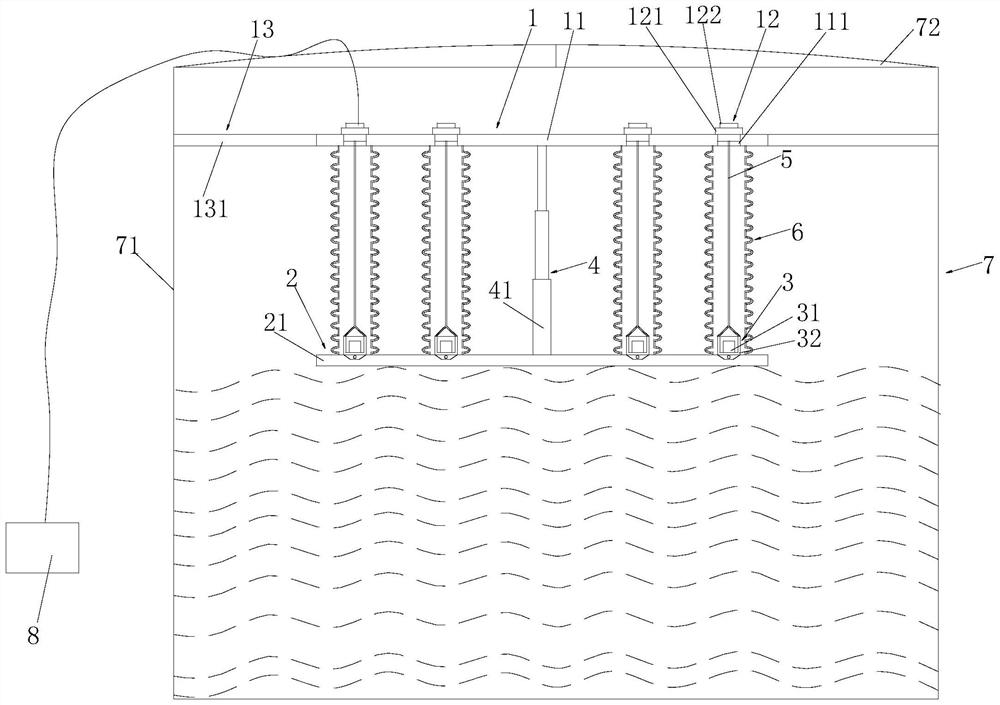

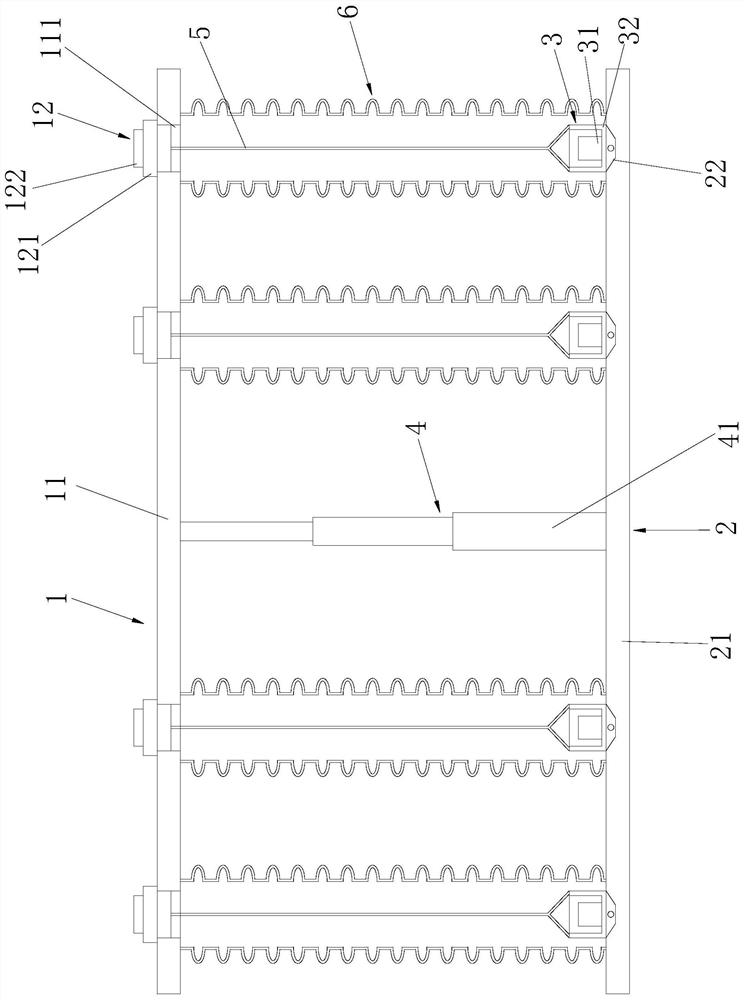

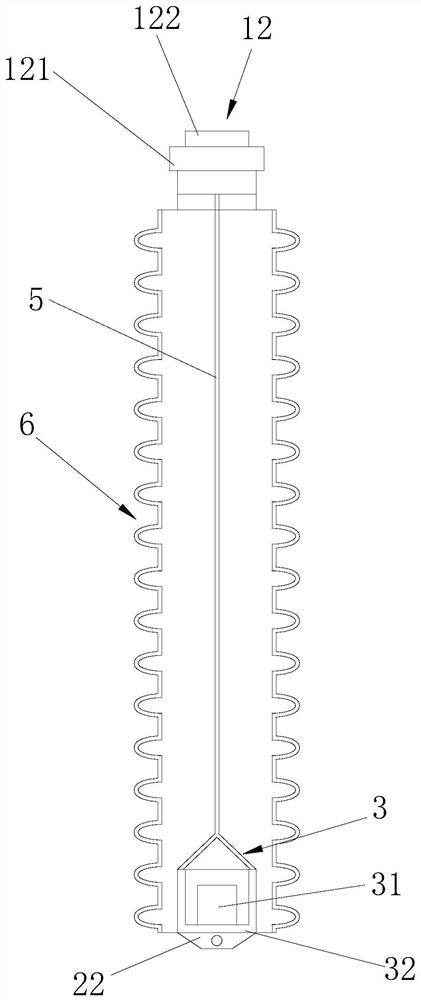

[0042] combine Figure 1 to Figure 3 , a fire alarm device for liquid sulfur storage tanks, including a positioning mechanism 1, a floating mechanism 2 and a temperature sensing mechanism 3, the positioning mechanism 1 includes a positioning partition 11 and a plurality of cover assemblies 12 embedded in the positioning partition 11, the positioning partition The lower end of 11 is connected with floating mechanism 2 through telescoping assembly 4 . The lower end of the cover assembly 12 is connected with the temperature sensing mechanism 3 provided on the floating mechanism 2 through the connecting wire 5 , and the connecting wire 5 and the temperature sensing mechanism 3 are covered with a telescopic protective sleeve 6 .

[0043] In this embodiment, the positioning partition 11 is in the shape of a rectangular plate, and the positioning partition 11 is connected to the inner wall of the liquid sulfur storage tank 7 through the first connecting component 13 . The first conn...

Embodiment 2

[0053] The fire alarm device for liquid sulfur storage tanks includes a positioning mechanism 1, a floating mechanism 2 and a temperature sensing mechanism 3. The positioning mechanism 1 includes a positioning partition and a plurality of cover assemblies embedded in the positioning partition. The lower end of the positioning partition is stretched Assembly 4 is connected to floating mechanism 2 . The lower end of the cover assembly is connected with the temperature sensing mechanism 3 provided on the floating mechanism 2 through the connecting wire, and the connecting wire and the temperature sensing mechanism 3 are covered with a telescopic protective sleeve 6 .

[0054] In this embodiment, the positioning partition is in the shape of an arc plate, and the positioning partition is connected to the inner wall of the liquid sulfur storage tank 7 through the first connecting component. The first connection assembly includes a first connection plate, the first connection plate i...

Embodiment 4

[0065] combine Figure 4 to Figure 6 A fire alarm device for a liquid sulfur storage tank, including a positioning mechanism and a temperature sensing mechanism 3, the temperature sensing mechanism 3 is arranged in the liquid sulfur storage tank through the positioning mechanism, and is connected with an alarm response system arranged outside the liquid sulfur storage tank.

[0066] The positioning mechanism includes a second inner floating plate 9 and an outer ring plate 91, and the outer end of the outer ring plate 91 is connected to the outer end of the second inner floating plate 9 through a plurality of second bar-shaped connecting plates 92. When the alarm device is used, the second inner floating plate 9 and the outer ring plate 91 all float on the liquid surface in the liquid sulfur storage tank.

[0067] The upper end of the second inner floating plate 9 is provided with a rotating mechanism 10 , and the temperature sensing mechanism 3 is connected to the rotating mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com