Integrated gas-water separator for fuel cell

A gas-water separator and fuel cell technology, applied in fuel cells, electrical components, electrochemical generators, etc., can solve problems such as poor integration, inability to detect internal air pressure and liquid level, easy freezing and blockage of drains, etc. , to achieve the effect of compact structure, good water separation effect and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

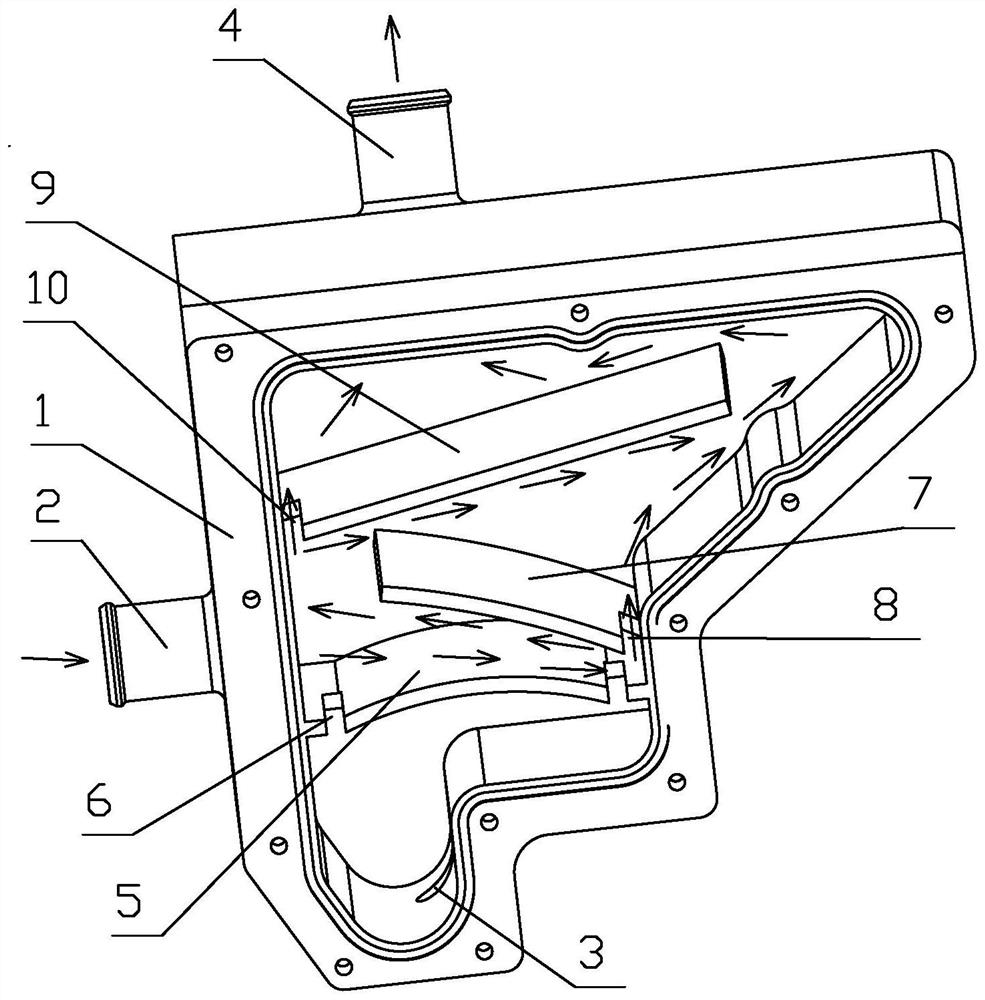

[0037] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

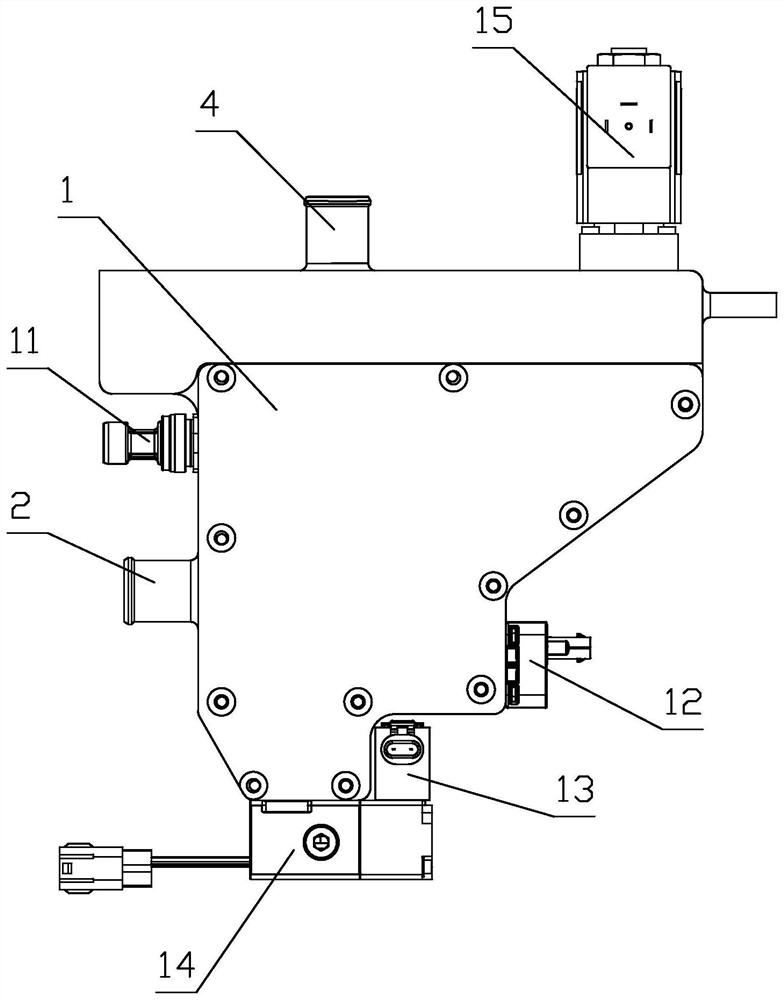

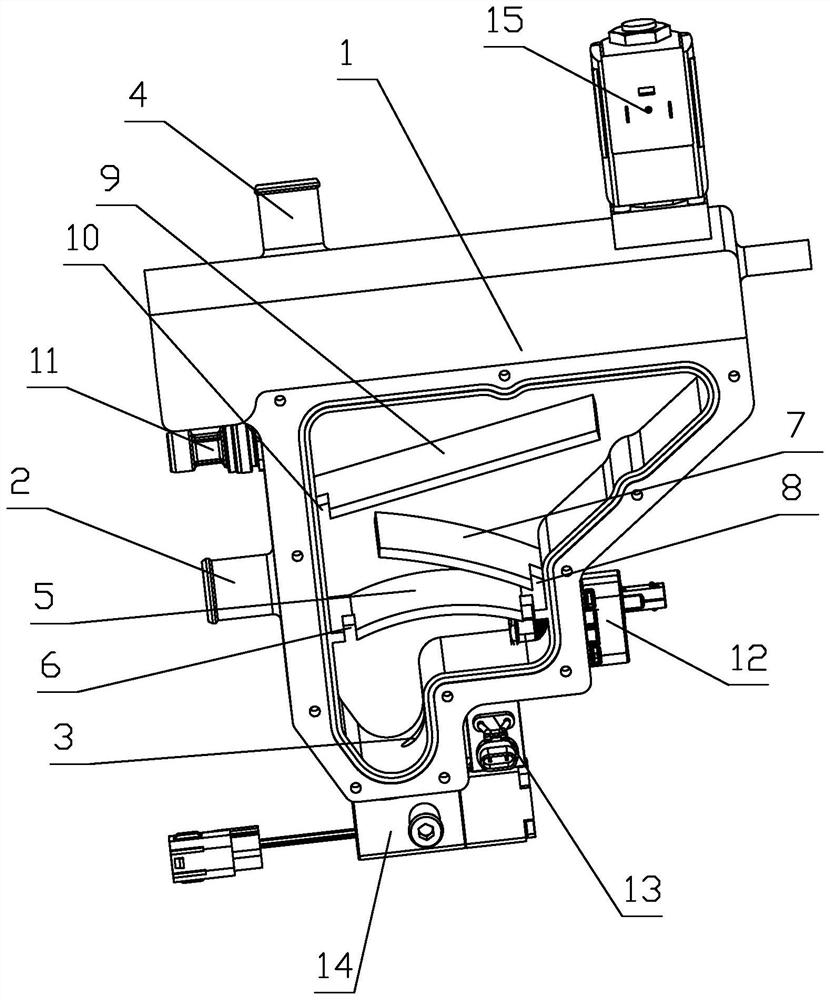

[0038] Such as Figure 1-3 As shown, an integrated gas-water separator for fuel cells includes a gas-water separator housing 1, a side of the gas-water separator housing 1 is provided with a hydrogen return inlet 2, and the bottom of the gas-water separator housing 1 is provided with Drain port 3, the top of gas-water separator housing 1 is provided with hydrogen return outlet 4, also includes:

[0039] Gas outlet detection pressure gauge 11, the gas outlet detection pressure gauge 11 is installed on the gas-water separator housing near the hydrogen return outlet, for detecting the gas pressure at the hydrogen return outlet;

[0040] A liquid level gauge 12, the liquid level gauge 12 is installed on the gas-water separator housing near the drain, and is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com