Online production device for copper-clad steel grounding material

A production device, copper-clad steel technology, applied in the direction of connection contact material, measuring device, connection, etc., can solve the problems of manual measurement, substandard quality, substandard service life and grounding effect of copper-clad steel grounding materials, etc. The effect of increasing the extrusion area and increasing the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

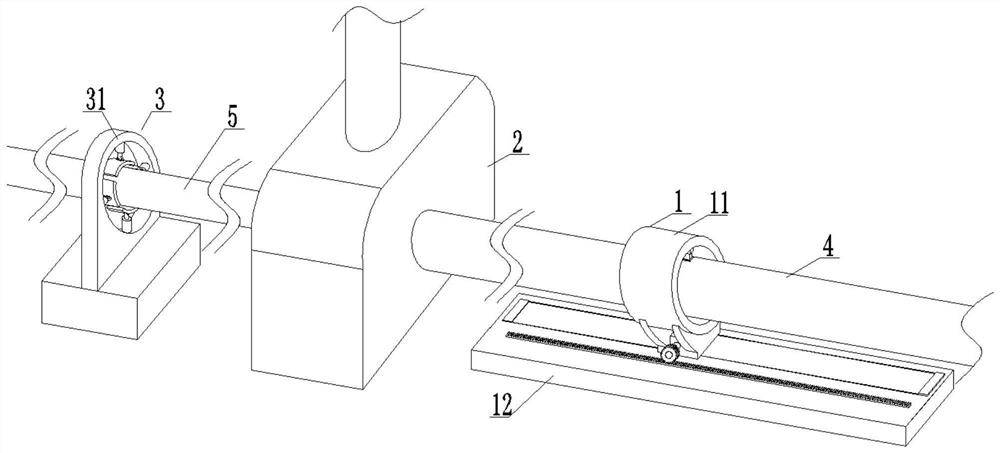

[0046] An online production device for copper-clad steel grounding materials, such as Figure 1 to Figure 8 As shown, it includes detection equipment 1, production equipment 2, debugging equipment 3 and a control system connected with the detection equipment 1 and debugging equipment 3 signals;

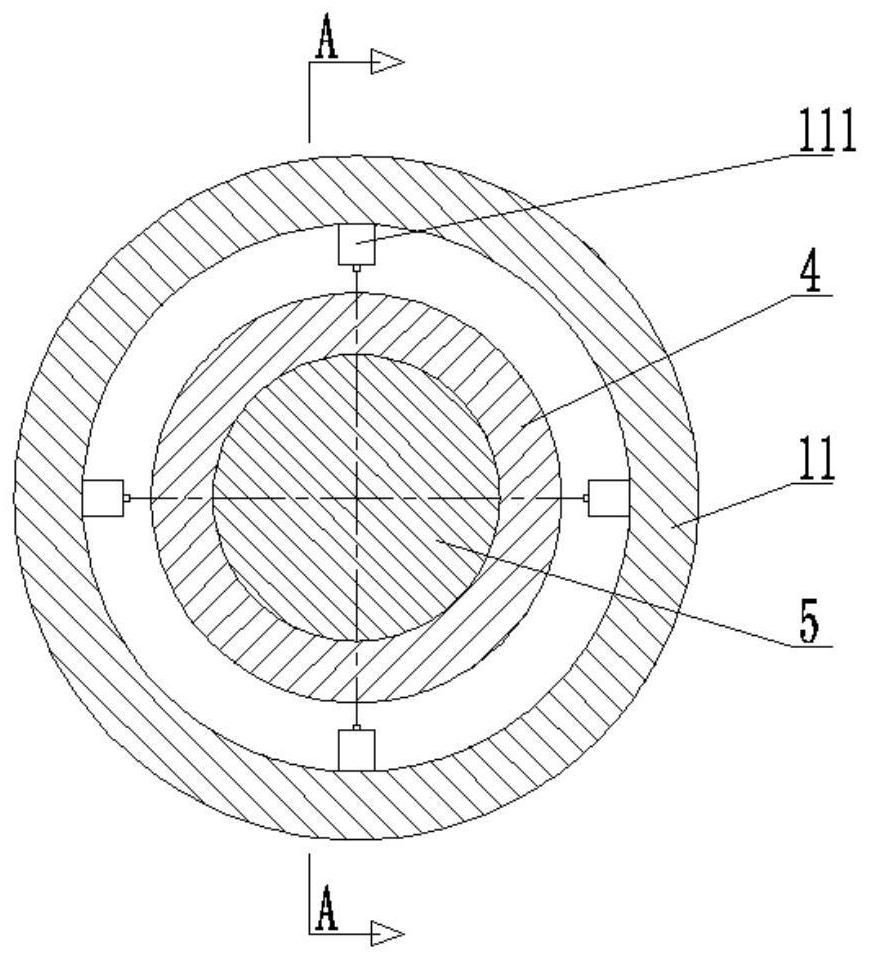

[0047] The manufacturing equipment 2 includes a main body for wrapping the copper clad layer on the steel core 5 to form a copper-clad steel grounding material 4. The two sides of the main body are respectively receiving ends for receiving the steel core 5 and for Output the output end of the copper-clad steel grounding material 4;

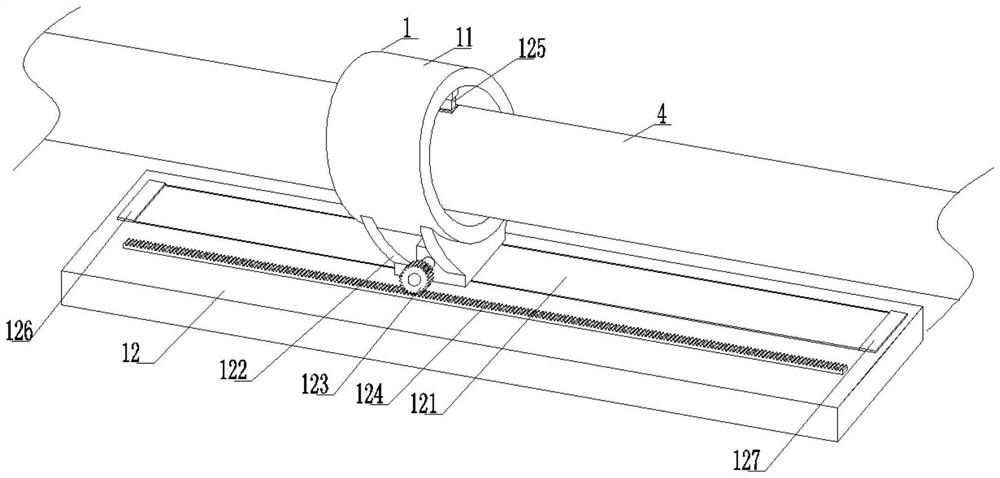

[0048] The detection device 1 is arranged on the side of the output end, and includes a detection sleeve 11 that can be sleeved outside the copper-clad steel grounding material 4 and can drive the detection sleeve 11 to follow the copper-clad steel grounding material. 4. The reciprocating movement assembly 12 that moves synchronously and resets, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com