Laminated material for forming a flexible container and flexible tube skirt comprising said laminated material

A technology of laminated materials and tube skirts, applied in the field of flexible tube skirts, can solve problems such as limiting the service life of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

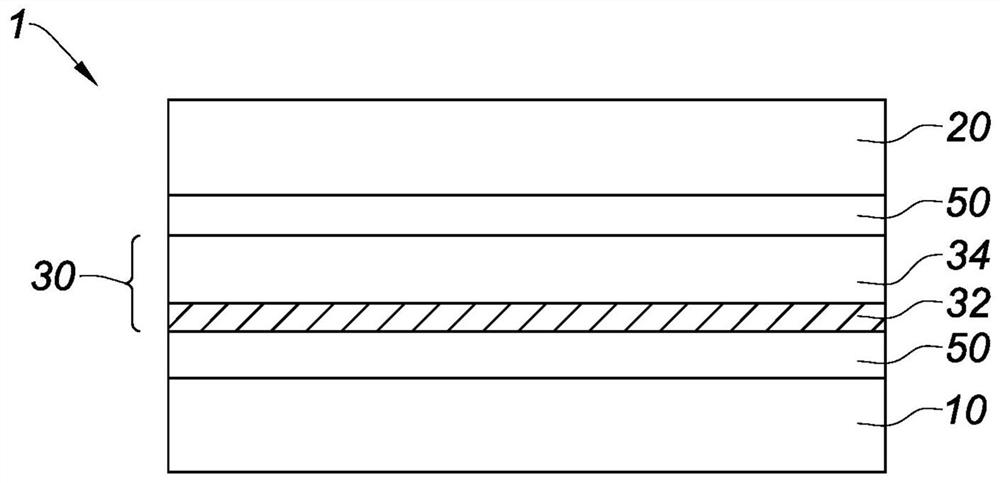

[0117] This embodiment is shown schematically in figure 1 middle. The embodiment consists of the following:

[0118] Outer layer 20 made of CPP,

[0119] the first adhesive layer 50,

[0120] carrier layer 34 made of BOPP,

[0121] The oxide material barrier layer 32 made of SiOx,

[0122] The second adhesive layer 50,

[0123] Inner layer 10 made of CPP.

[0124] Laminate 1 is obtained by adhesive lamination of these various layers. The outer layer 20 has a thickness of 100 μm. Carrier layer 34 and barrier layer 32 of oxide material represent barrier layer 30 . The SiOx barrier layer 32 has a thickness of less than 0.1 μm. The barrier layer has a thickness of 20 μm. The inner layer 10 has a thickness of 100 μm. Laminate 1 had a total thickness of 228 μm.

Embodiment approach 2

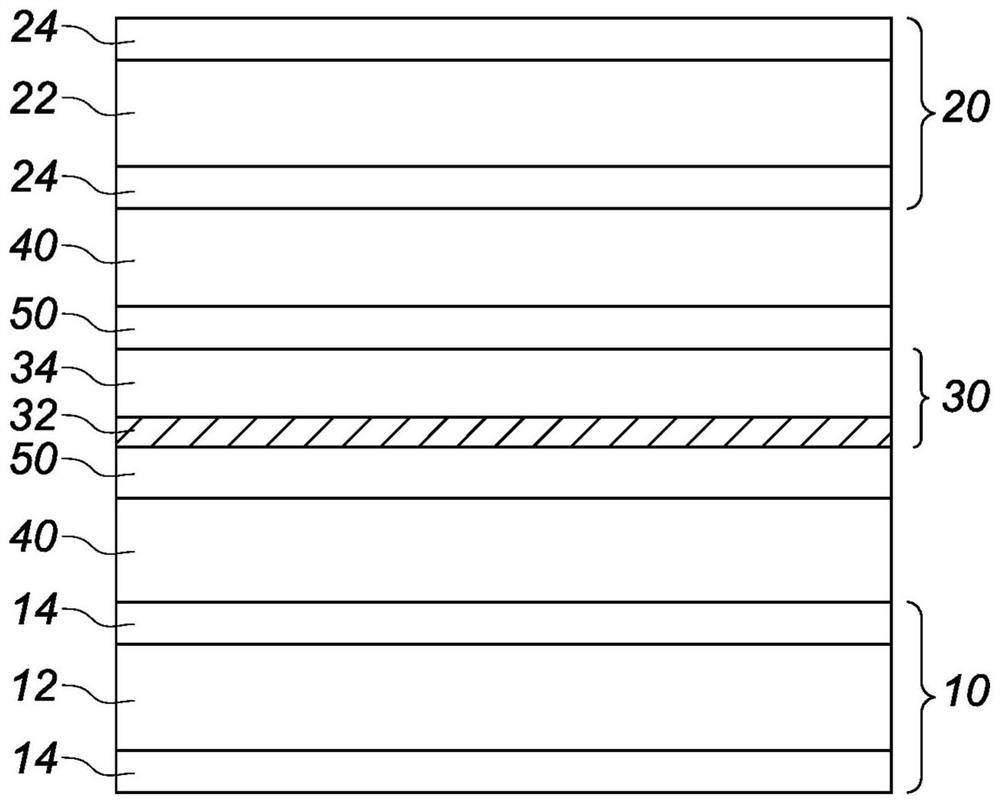

[0126] The embodiment consists of the following:

[0127] The surface layer 24 made of CPP,

[0128] The core layer 22 made of CPP,

[0129] The surface layer 24 made of CPP,

[0130] the first adhesive layer 50,

[0131] carrier layer 34 made of BOPP,

[0132] The oxide material barrier layer 32 made of SiOx,

[0133] The second adhesive layer 50,

[0134] Surface layer 14 made of CPP,

[0135] The core layer 12 made of CPP,

[0136] Skin 14 made of CPP.

[0137] Laminate 1 is obtained by extrusion lamination of these various layers. The skin layer 24 and the core layer 22 represent the outer layer 20 . Each of the skin layers 24 has a thickness of 10 μm, and the core layer 22 has a thickness of 80 μm. Therefore, the outer layer 20 has a thickness of 100 μm. Carrier layer 34 and barrier layer 32 of oxide material represent barrier layer 30 . The SiOx barrier layer 32 has a thickness of less than 0.1 μm. The barrier layer has a thickness of 18 μm. The skin layer ...

Embodiment approach 3

[0139] This implementation: mode is shown schematically in figure 1 middle. The embodiment consists of the following:

[0140] Outer layer 20 made of CPP,

[0141] the first adhesive layer 50,

[0142] carrier layer 34 made of BOPP,

[0143] The oxide material barrier layer 32 made of AlOx,

[0144] The second adhesive layer 50,

[0145] Inner layer 10 made of CPP.

[0146] Laminate 1 is obtained by extrusion lamination of these various layers. The outer layer 20 has a thickness of 100 μm. Carrier layer 34 and barrier layer 32 of oxide material represent barrier layer 30 . The AlOx barrier layer 32 has a thickness of less than 0.1 μm. The barrier layer has a thickness of 16 μm. The inner layer 10 has a thickness of 100 μm. Laminate 1 had a total thickness of 224 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com