Paddy rice screening separator

A technology of separator and rice paddy, which is applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of easy clogging of sieve holes and inability to adjust sieving time, so as to avoid high-pressure air scouring, excellent anti-clogging effect, and applicable wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

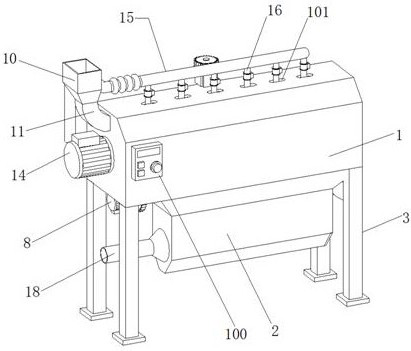

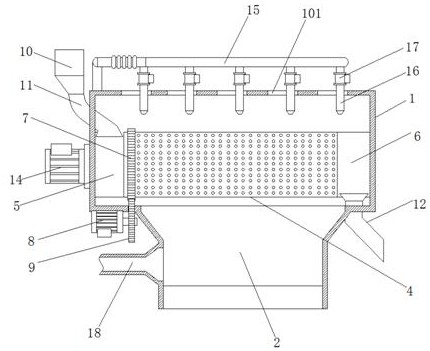

[0037] Embodiment 1 discloses a kind of paddy screening separator suitable for different paddy after shelling, refer to the attached figure 1 And attached figure 2 Its main body includes a screening box 1 and a dust collecting bucket 2. The dust collecting bucket 2 is connected with the lower surface of the screening box 1, and is used to collect and sieve the falling dust and impurities. A leg 3 is connected to each place, and a control panel 100 for controlling the whole paddy screening and separating machine is arranged on the screening cabinet 1 .

[0038] Reference attached image 3 And attached Figure 4 , a horizontally arranged screen cylinder 4 is arranged inside the screening cabinet 1, and a large number of screen holes are opened on the cylinder body of the screen cylinder 4, and ring bodies 401 are connected to both ends of the screen cylinder 4. At the same time, the left and right ends of the inner cavity of the screening cabinet 1 are respectively fixedly c...

Embodiment 2

[0045] Embodiment 2 discloses a paddy screening separator with anti-clogging function improved on the basis of Embodiment 1. Its similarities with Embodiment 1 will not be described again in Embodiment 2. The difference is that:

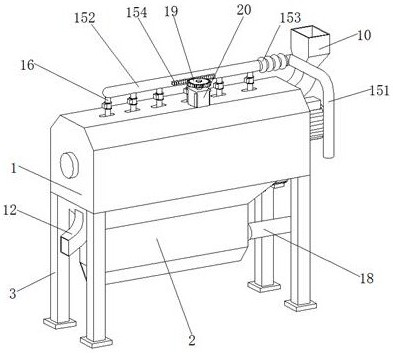

[0046] Reference attached figure 1 And attached Figure 6 , this embodiment 2 is also provided with a compressed air pipe 15 parallel to the screen cylinder 4 directly above the screening cabinet 1, and one end of the compressed air pipe 15 is connected to a compressed air source (not shown in the figure), and compressed A master valve is arranged at the connection between the air pipe 15 and the compressed air source. At the same time, the lower surface of the compressed air pipe 15 is connected with a plurality of compressed exhaust branch pipes 16 at equal intervals, and the lower end of each compressed exhaust branch pipe 16 stretches into the inside of the screening cabinet 1 and is arranged against the screen cylinder 4, and each A solenoid v...

Embodiment 3

[0051] Embodiment 3 discloses an improved paddy screening separator based on Embodiment 2, which mainly aims at the deficiency that Embodiment 2 cannot effectively dredge the screen holes between two adjacent compression exhaust branch pipes 16, and its The same as embodiment 2 will not be described again, the difference is:

[0052] Reference attached figure 1 , attached figure 2 And attached Figure 6 , the present embodiment 3 is also provided with a bar-shaped mouth 101 corresponding to each compression exhaust branch pipe 16 on the upper surface of the screening cabinet 1, and each compression exhaust branch pipe 16 is stretched into the screen through the bar-shaped mouth 101 The cabinet 1 is arranged facing the screen drum 4 .

[0053] Simultaneously, the compressed air pipe 15 among the present embodiment 2 is divided into three sections and is arranged, and the first section is the air intake hard pipe 151 that is connected with the compressed air source, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com