Ceramic product thread machining method

A thread processing and product technology, applied to metal processing equipment, manufacturing tools, grinding workpiece supports, etc., can solve the problems of not using metal threads, fast tool consumption, long processing time, etc., to achieve easy and reliable insertion and high processing efficiency , Processing precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

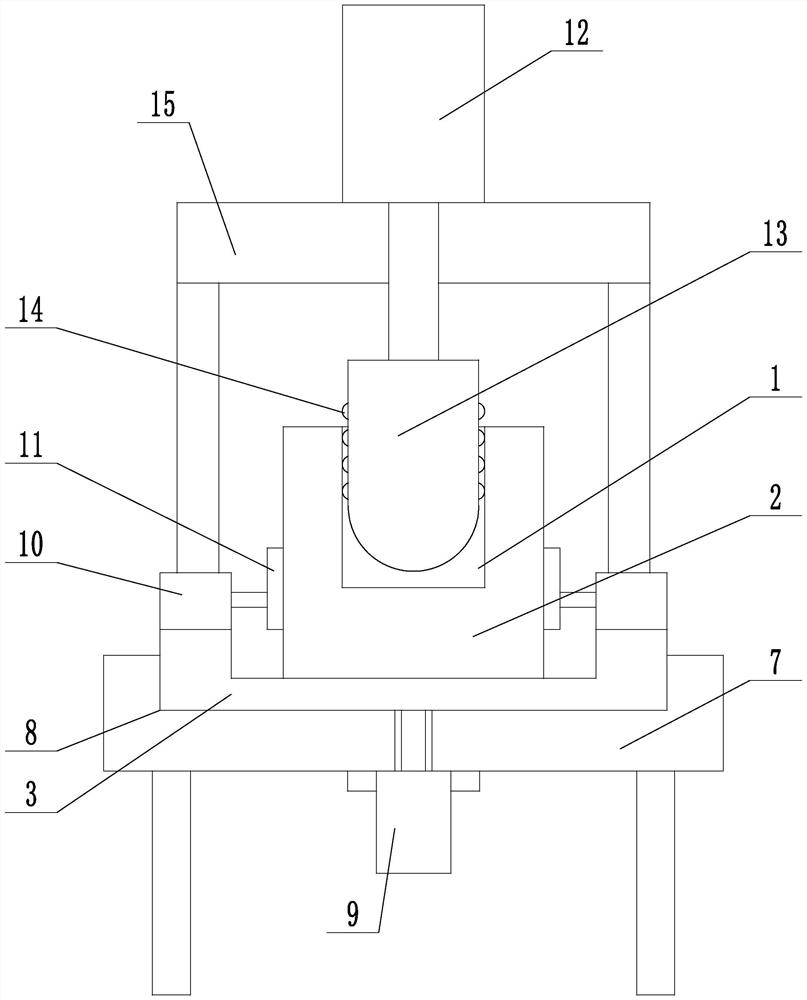

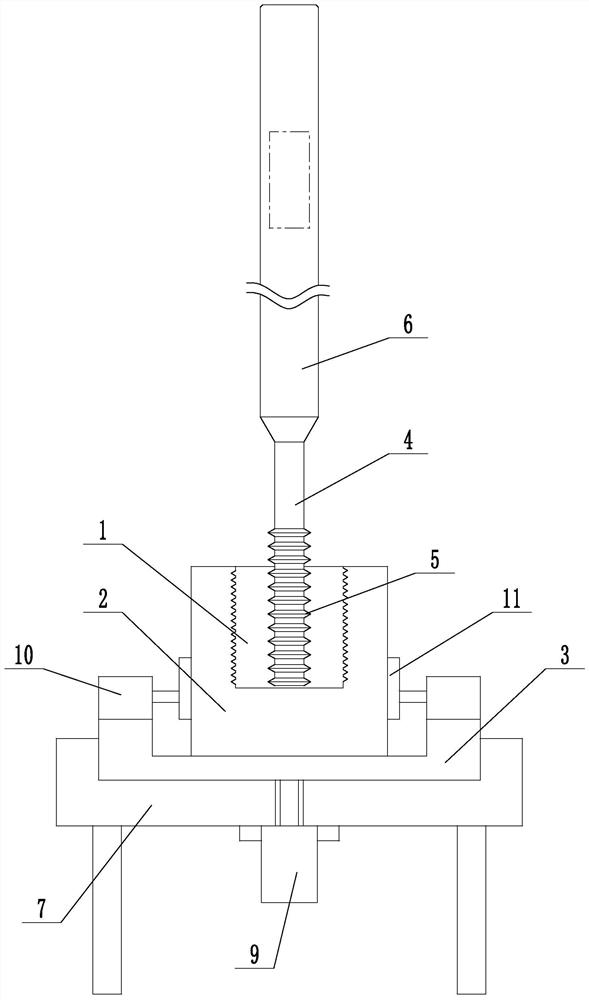

[0021] Embodiment: a kind of thread processing method of ceramic products (see attached figure 1 , attached figure 2 ), including the following steps: a. placing the ceramic product 2 with the processing hole 1 on the turntable 3; b. centering the processing hole so that the axis of the processing hole coincides with the rotation axis of the turntable, and clamping the ceramic product Product; c, the tool is inserted into the machining hole, the tool 4 is provided with a number of equally spaced blades 5, and the distance between two adjacent blades is n times the pitch h of the thread to be processed; d, the tool rotates towards The inner wall of the machining hole, the blade is ground in contact with the inner wall of the machining hole, and at the same time the tool moves upwards, the turntable drives the ceramic product to rotate, the number of turns of the turntable is n+0.5, and the distance that the tool moves upward is h (n+0.5); e, the tool Separate from the inner w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com