Silk-screen printing device and printing method thereof

A technology of screen printing device and screen printing plate, applied in the direction of screen printing, screen printing machine, printing device, etc. Cumbersome and other problems, to achieve the effect of improving the scope of application, reasonable structure and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

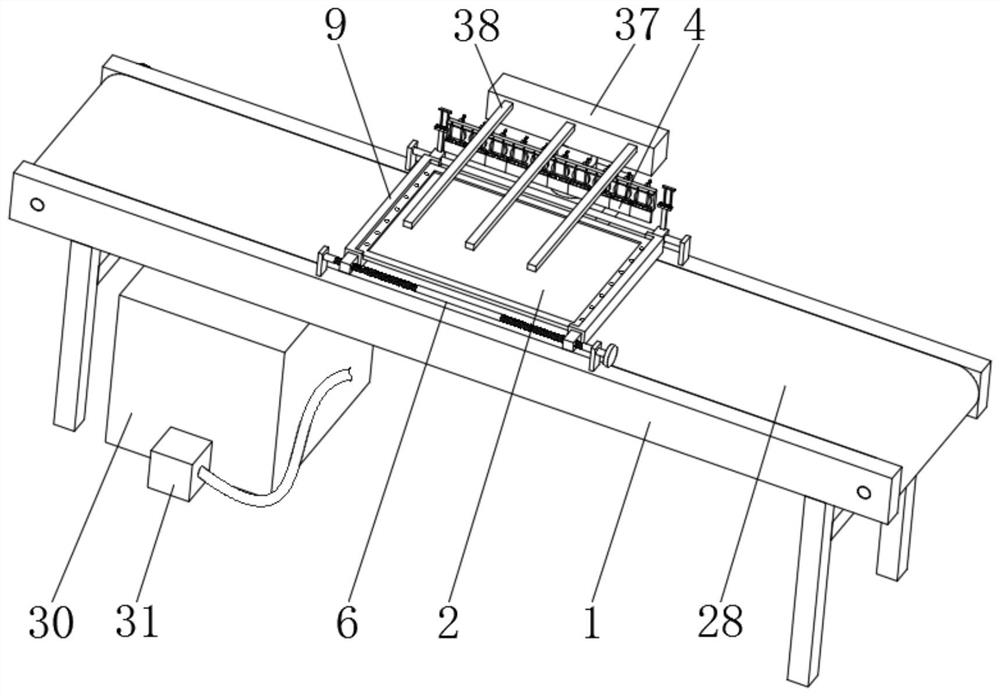

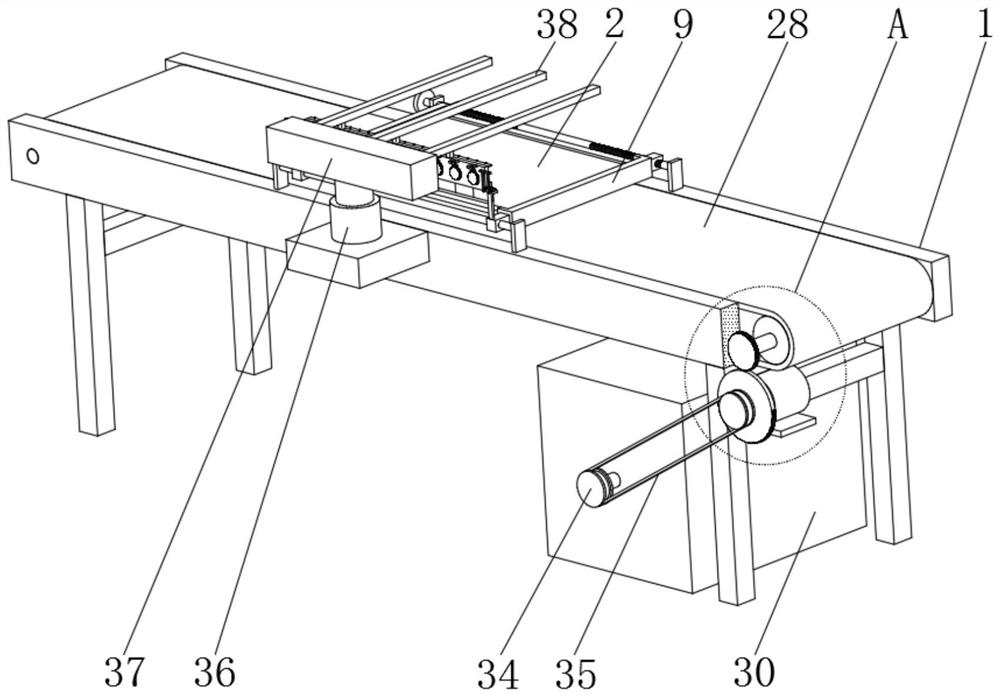

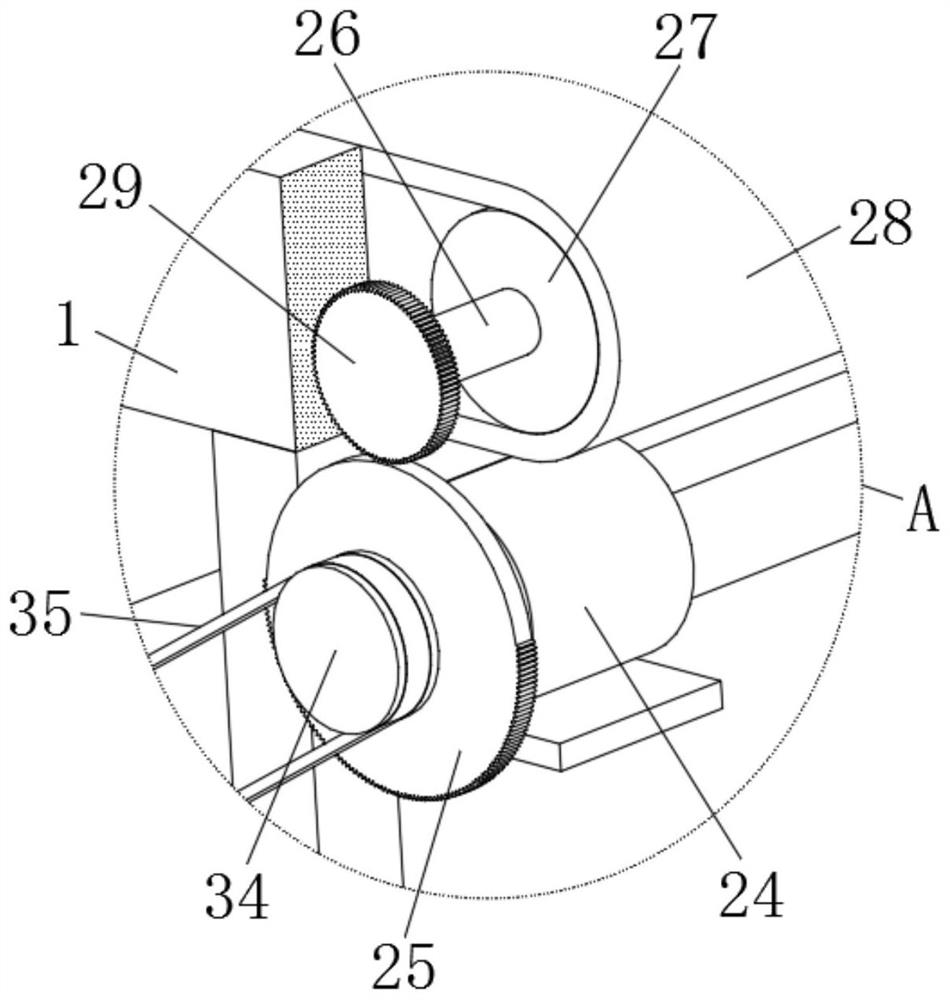

[0044] Example: Figure 1-8 A screen printing apparatus shown, comprises a printing table 1, the printing station 1 may be any of the prior art by printing metal stage.

[0045] Top printing station 1 is provided with a screen printed version 2, release 2 screen printing may be any of a screen plate prior art structure, for example a metal plate screen.

[0046] 1 connected with a printing table mounting assembly 2 adapted for adapting stencil mounting version thereof, adjusting means connected to the adapter mounting assembly, screen printing version thereof disposed directly above the transverse plate 2, a support 3, a cross-support plate 3 may be any of a prior art horizontal metal plate.

[0047] Horizontal support plate connected to a plurality of uniformly lifter assembly 3, the lift assembly is connected with a plurality of phase matching combination blade 4, the blade 4 may be a combination of any of the prior art printing of the blade structure, such as a metal blade.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com