Environment-friendly transportation device applied to electromechanical engineering

A transportation device and engineering technology, which is applied in the direction of transportation and packaging, spraying devices, cranes, etc., can solve the problem of sticking to the surface of the conveyor, and achieve the effect of easy blocking and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

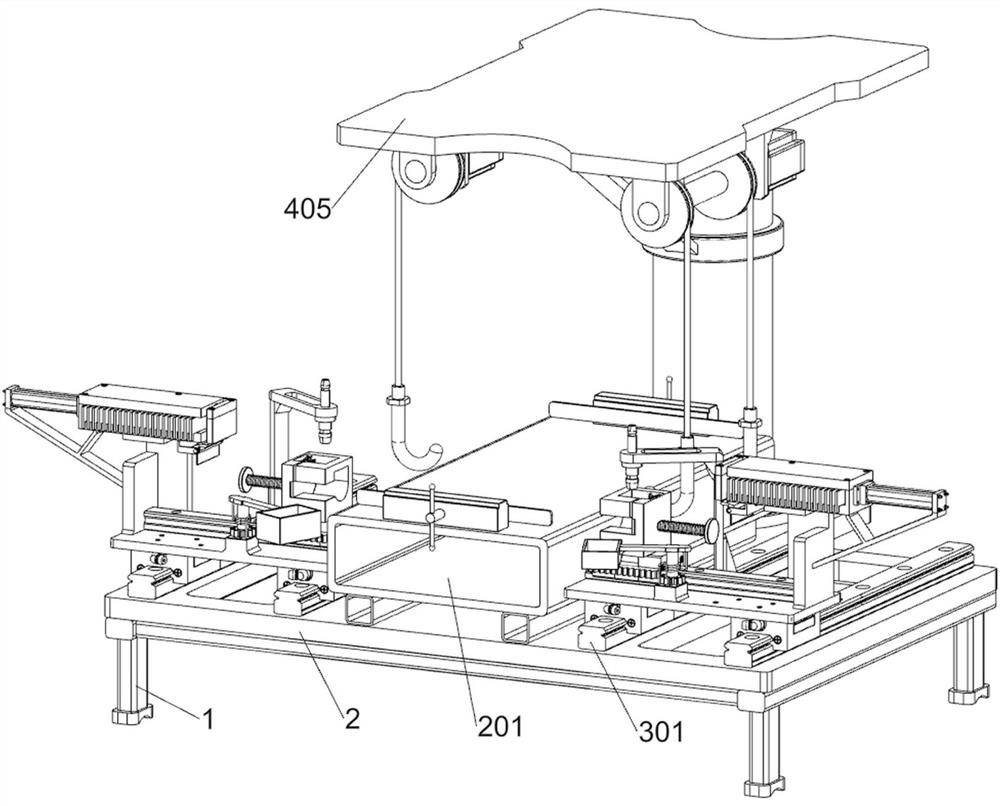

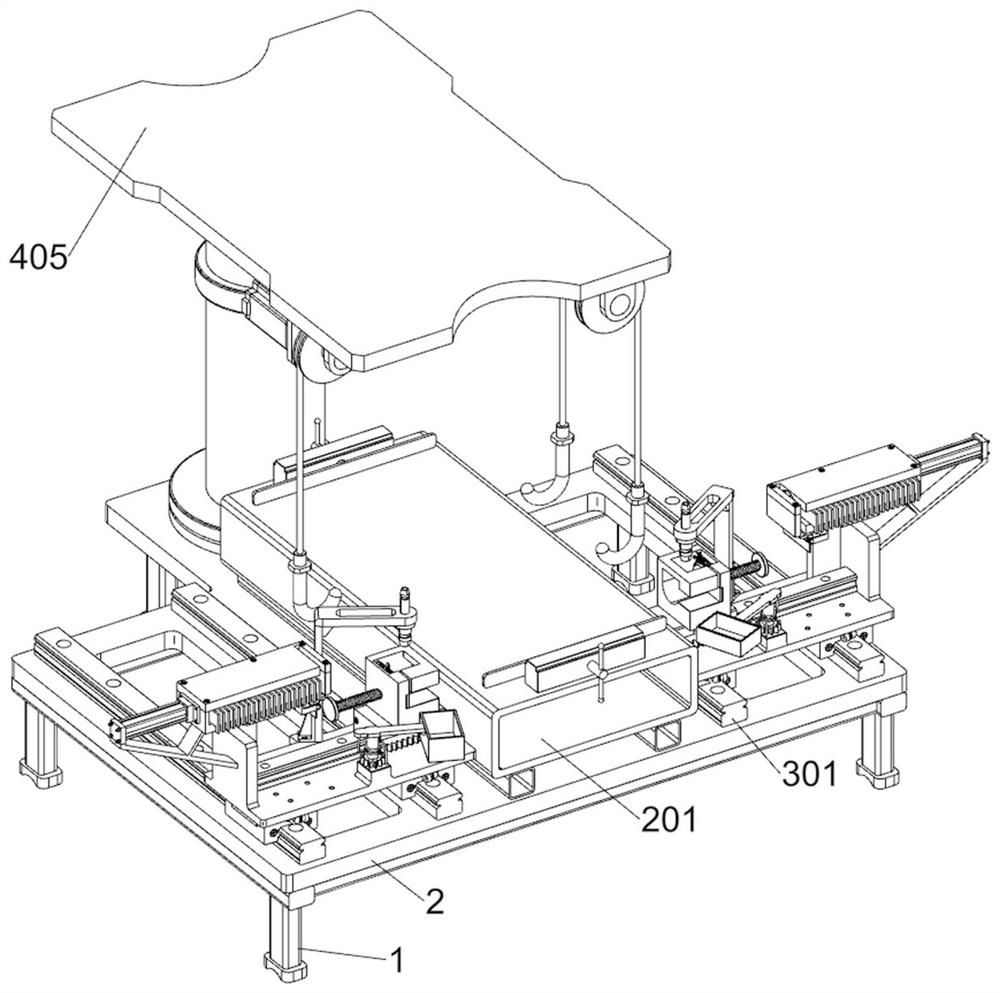

[0031] An environmentally friendly transportation device used in mechanical and electrical engineering, such as Figure 1-11 As shown, it includes a bottom frame 1, a bottom plate 2, a positioning system, a sealing system and a handling system; the upper side of the bottom frame 1 is connected with a bottom plate 2; A sealing system is respectively connected to the right side of the side, and the two sealing systems are left-right symmetrical;

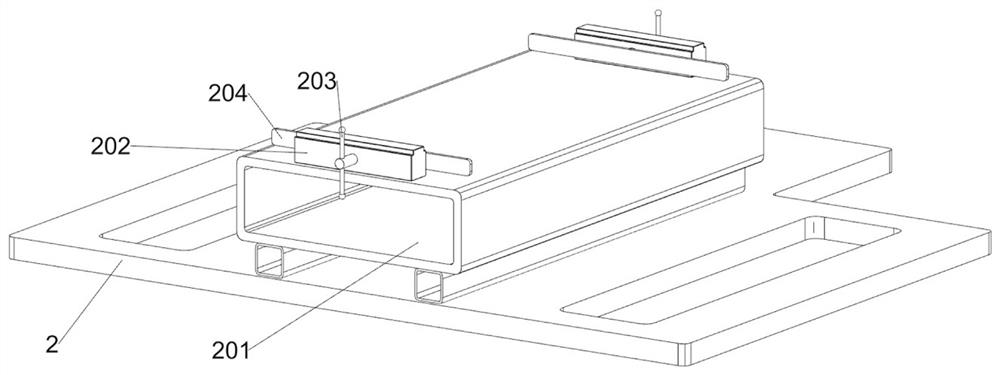

[0032]The positioning system includes a first support frame 201, a first fixed block 202, an adjustment rod 203 and an adjustment plate 204; the upper middle part of the bottom plate 2 is fixedly connected with the first support frame 201; Each of the rear parts is fixedly connected with a first fixing block 202 ; the middle parts of the two first fixing blocks 202 are screwed with an adjusting rod 203 ;

[0033] The blocking system on the right includes a first electric slide rail 301, a first mounting plate 302, a second electric sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com