A water-based paint for plastic products

A technology for water-based coatings and plastic products, applied in pigment slurry, polyurea/polyurethane coatings, coatings, etc., can solve the problems of difficult dispersion, poor covering power, uneven chromaticity, etc., and achieve excellent compatibility, stability, Good coverage and even shade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

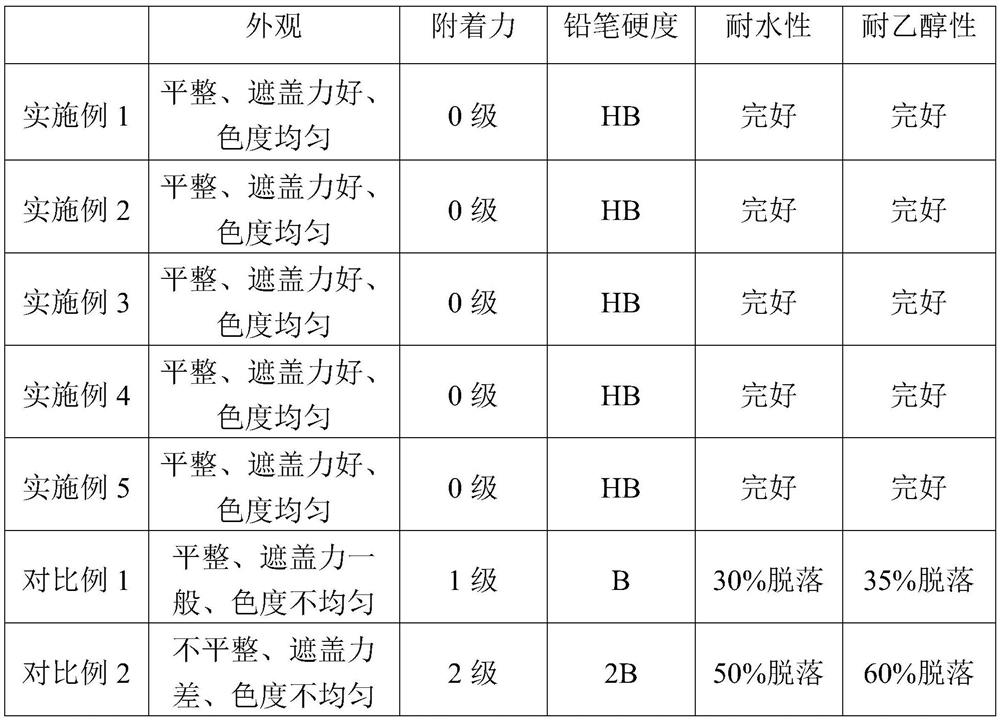

Examples

preparation example Construction

[0026] Preparation of Phospholipid-Based Wetting and Dispersing Agents:

[0027] PEGMA (Mn=300g / mol), 4-cyano-4-(thiocarbonylbenzoyl)valeric acid (dithio reagent) and AIBN were added to the reaction flask at a molar ratio of 30:1:0.01, Add 1,4-dioxane and stir to dissolve it, react at 60° C. for 2 h under nitrogen atmosphere, and then precipitate in anhydrous methanol to obtain pPEGMA with a molecular weight of 8300 g / mol.

[0028] Add 20g of soybean lecithin, 0.8g of cation exchange resin and 0.7g of acetic acid into the reaction flask, stir and heat up to 50°C, slowly add a certain amount of 5g of hydrogen peroxide dropwise, after the dropwise addition, continue to stir and react for 5h; Filtrate after the end, and the filtrate is treated with an alkaline solution to neutrality and then concentrated to obtain epoxidized soybean lecithin;

[0029] In terms of amino groups in epoxidized soybean lecithin, its mol ratio with glycidyl methacrylate (GMA) is 1:1.2, then the amount...

Embodiment 1

[0036] Example 1: 15 parts of polyurethane acrylic resin and 15 parts of high hydroxyl acrylic resin, 10 parts of carbon black slurry, 1 part of polyether modified acrylic leveling agent, 1 part of polyester accelerator, 1 part of dipropylene glycol monomethyl ether and 1 part propylene glycol monomethyl ether acetate, 2 parts cymel 325 and 20 parts water.

[0037] Carbon black slurry: mix 6wt% of wetting and dispersing agent A with 40wt% of carbon black pigment, add the carbon black pigment slowly in stages, stir and disperse quickly during the addition process; continue stirring for 30 minutes after adding the carbon black pigment, then add 1wt% wetting and dispersing agent B, finally add water to make the total mass 100%, continue to stir until a uniform slurry is obtained; finally, ball mill in a ball mill to obtain a carbon black slurry.

Embodiment 2

[0038] Example 2: 20 parts of polyurethane acrylic resin and 20 parts of high hydroxyl acrylic resin, 15 parts of carbon black pulp, 1.5 parts of polyether modified acrylic leveling agent, 1.5 parts of polyester accelerator, 1.5 parts of dipropylene glycol monomethyl ether and 1 part propylene glycol monomethyl ether acetate, 2 parts cymel 325 and 25 parts water.

[0039] Carbon black slurry: Mix 7wt% of wetting and dispersing agent A with 50wt% of carbon black pigment, add the carbon black pigment slowly in stages, stir and disperse quickly during the addition process; continue stirring for 30 minutes after adding the carbon black pigment, then add 1wt% wetting and dispersing agent B, finally add water to make the total mass 100%, continue to stir until a uniform slurry is obtained; finally, ball mill in a ball mill to obtain a carbon black slurry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com