Energy-saving beer brewing fermentation technology

A technology of beer fermentation and technology, which is applied in the field of energy-saving brewing and beer fermentation, can solve the problems such as inability to selectively cool, achieve the effects of ensuring cooling effect, avoiding waste, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following descriptions are only preferred implementations of the present invention, and the scope of protection is not limited to this embodiment. All technical solutions under the idea of the present invention shall belong to the scope of protection of the present invention. At the same time, it should be pointed out that for those skilled in the art, some improvements and modifications without departing from the principle of the present invention should also be regarded as the protection scope of the present invention.

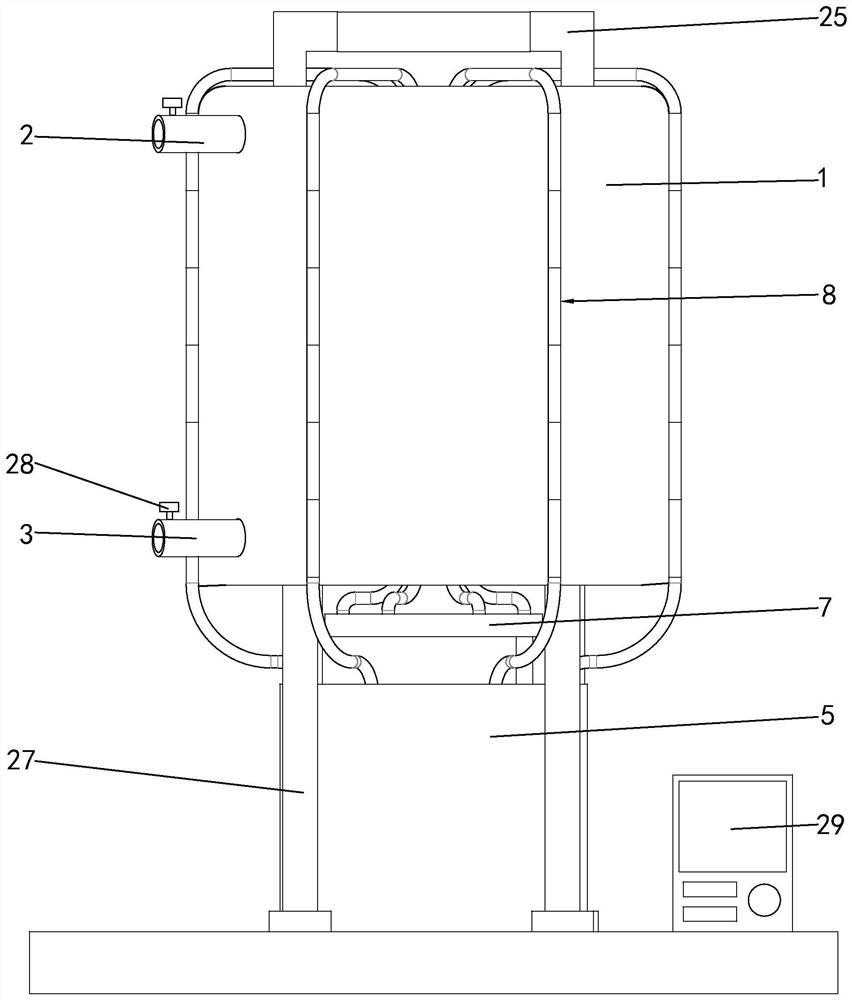

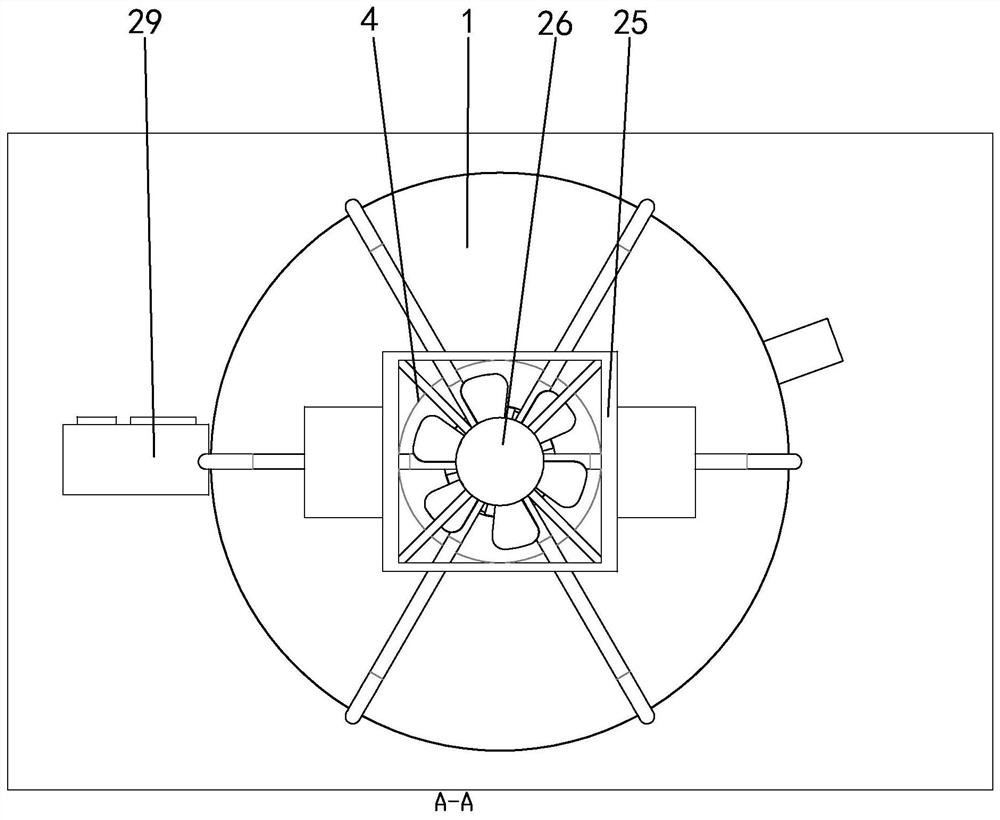

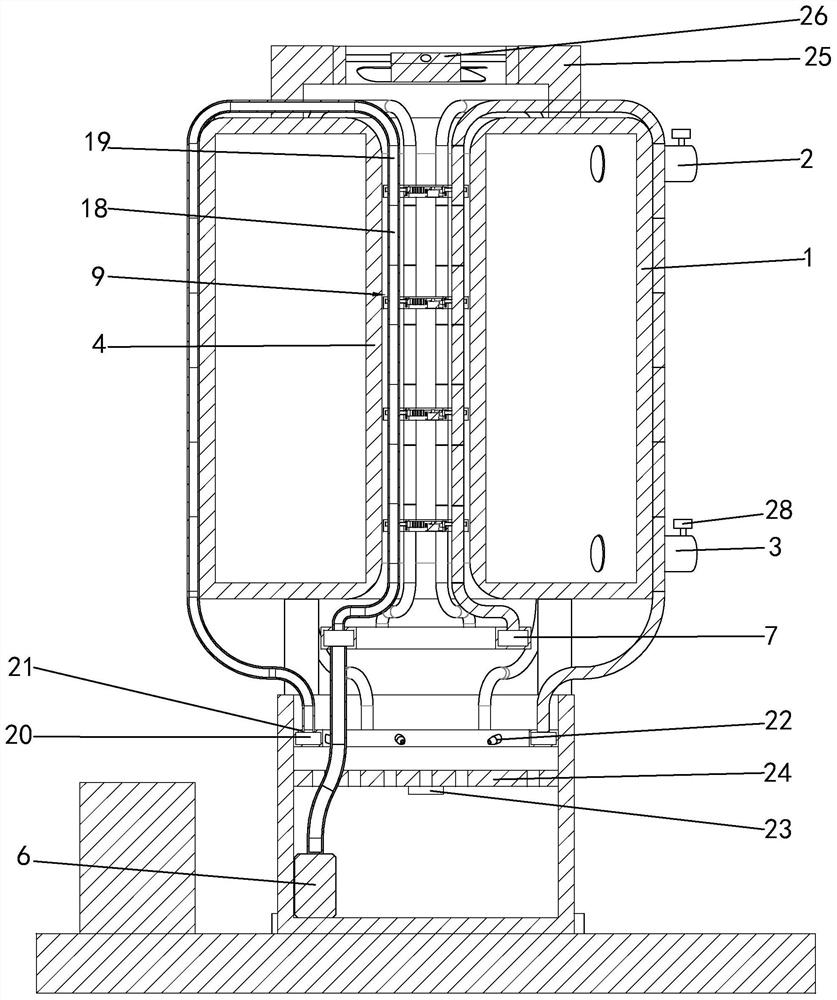

[0032] See Figures 1 to 5 As shown, an energy-saving brewing beer fermentation technology includes a beer tank 1 and a water inlet pipe 2 and an outlet pipe 3 running through the side wall of the beer tank 1. The bottom of the beer tank 1 is fixedly connected with a fixed frame 27 for supporting the beer tank 1 , the fixed frame 27 supports the beer can 1, and the side of the beer can 1 is provided with a controller 29 which plays a control eff...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap