Efficient cone yarn dewatering device

A dewatering device and yarn package technology are applied in the field of package yarn production, which can solve the problems of long space occupied by the dehydration process, poor continuous operability, and impact on package yarn production efficiency, etc., and achieve the effects of efficient dehydration time occupation and reasonable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

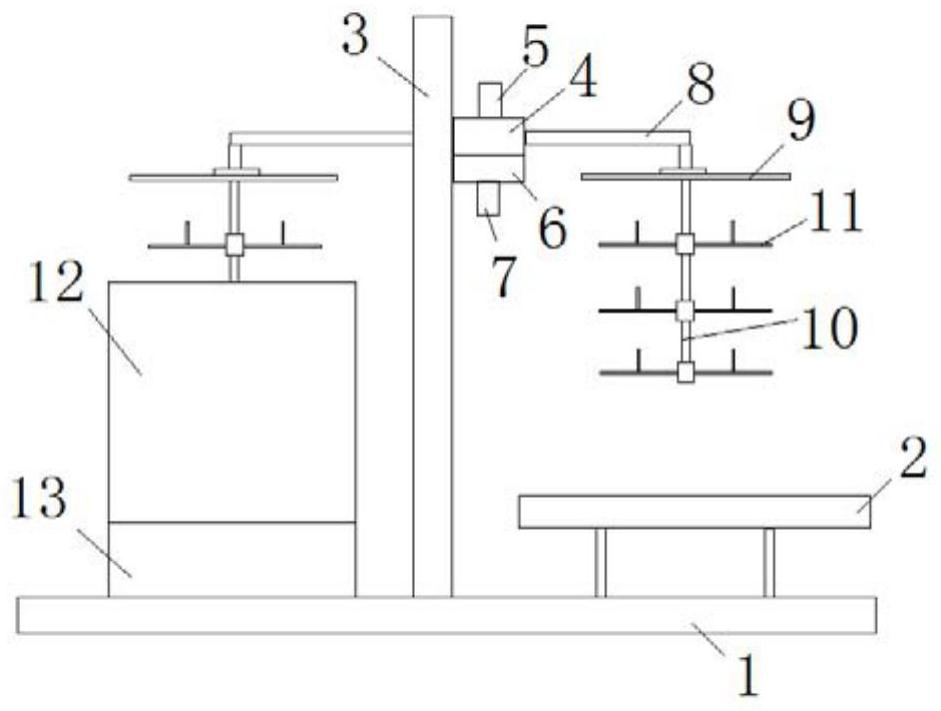

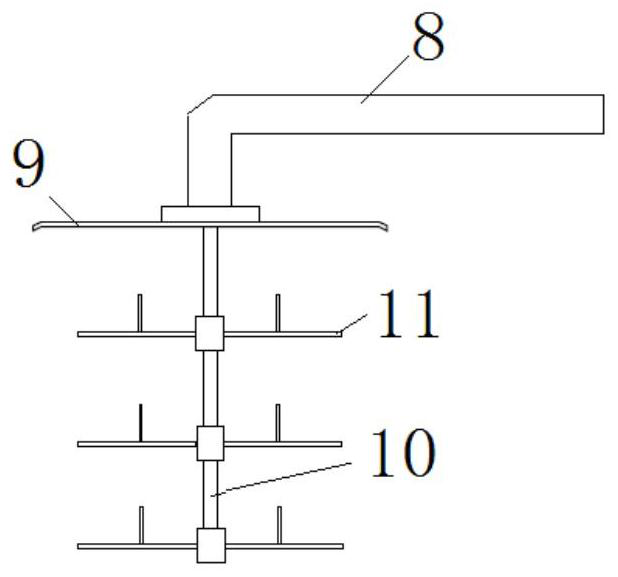

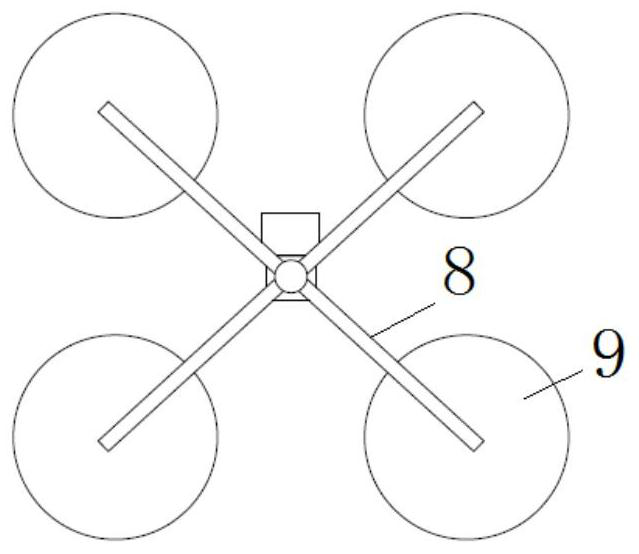

[0024] like Figure 1 to Figure 3 As shown, the high-efficiency bobbin dehydration device includes a bottom plate 1, a dehydrating cylinder 12, a stand 3, a lifting block 6, a rotating disk 4, and a group of bobbin lifting and lowering turrets for storing bobbins. The bobbin lifting and turret is Spin rack that fits into the spin drum.

[0025] Lifting block 6 can be lifted and set on the stand, and the rotating disc can be rotatably set on the lifting block, and a group of bobbin lifting turrets are connected with the rotating disc through corresponding rotating support arms 8 . A group of dehydration racks for storing bobbins can be lifted and rotated. Some dehydration racks in the device can be located in the dehydration drum for dehydration treatment, while others are located outside the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com