Intelligent lubricating system for unmanned travelling crane and control method of intelligent lubricating system

A technology for lubrication systems and pedestrian vehicles, which is applied in the field of intelligent lubrication systems for unmanned vehicles and its control, and can solve problems such as difficulties in dynamic observation and monitoring of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

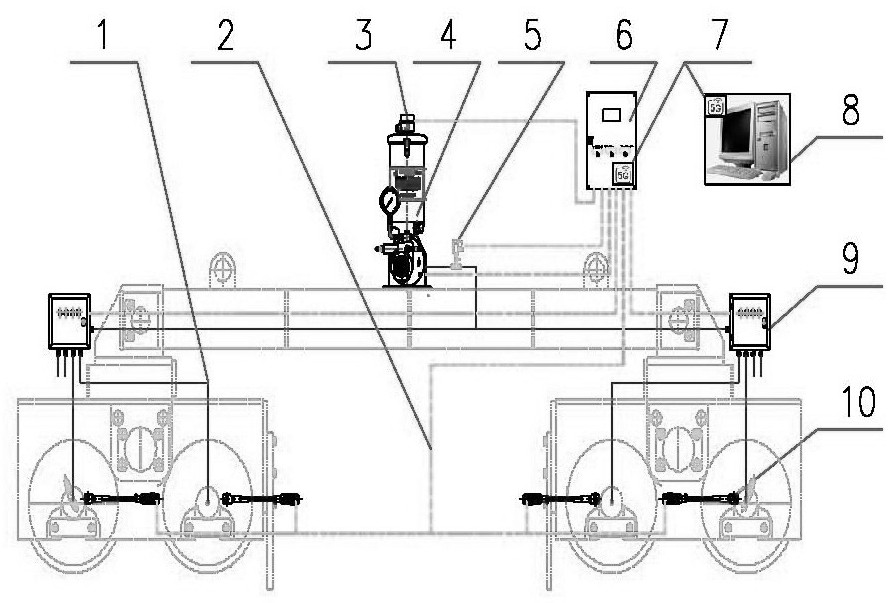

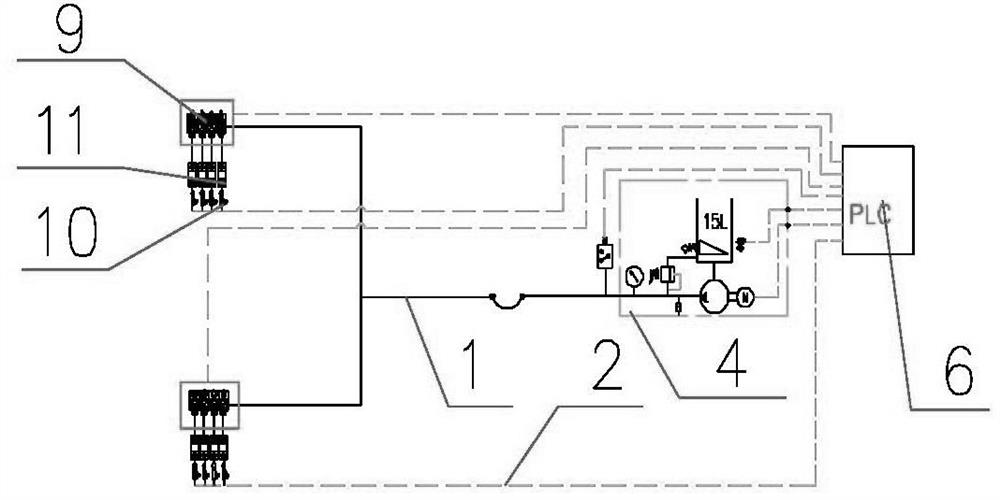

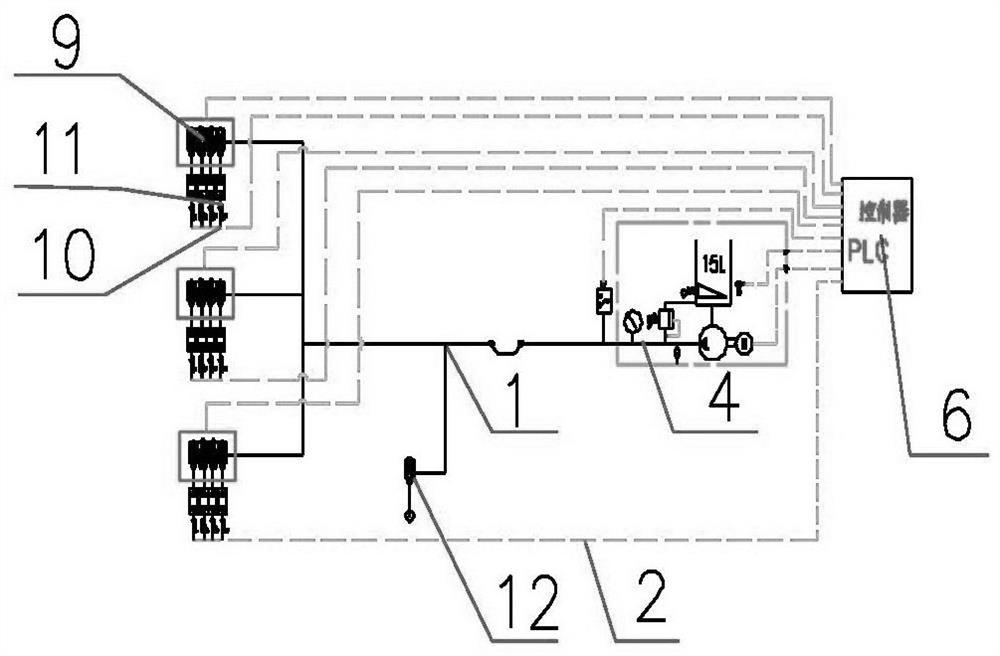

[0023] Such as figure 1 As shown, an intelligent lubrication system for unmanned vehicles includes a lubrication circuit device, a sensor device and a control device. The lubrication circuit device includes a high-pressure electric hydraulic pump 4 and an electromagnetic oiler 9, and a high-pressure electric hydraulic pump 4 and an electromagnetic oiler 9 Connected through the high-pressure lubricating oil pipe 1, the electromagnetic oil feeder 9 supplies oil to the bearing of the driving through the high-pressure lubricating oil pipe 1; the sensor device includes an oil level sensor 3, a pressure sensor 5, and a temperature sensor 10. On the pump 4, the pressure sensor 5 is installed on the high-pressure lubricating oil pipe 1, the pressure sensor 5 monitors the oil pressure of the main pipeline in real time, the temperature sensor 10 is installed at the bearing, and the temperature sensor 10 monitors the temperature of the bearing 11 in real time under working conditions; the...

Embodiment 2

[0036] Unmanned driving intelligent lubrication system, electromagnetic oiler 9 can also feed oil to the wire rope pulley shaft 12 of driving through high-pressure lubricating oil pipe 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com