Lucid ganoderma airing equipment

A technology of ganoderma and equipment, applied in the field of ganoderma drying equipment, can solve the problems of lowering the quality of ganoderma, consuming a lot of manpower and time, prolonging or shortening the drying time of ganoderma, and achieving the effect of improving the uniformity and quality of drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

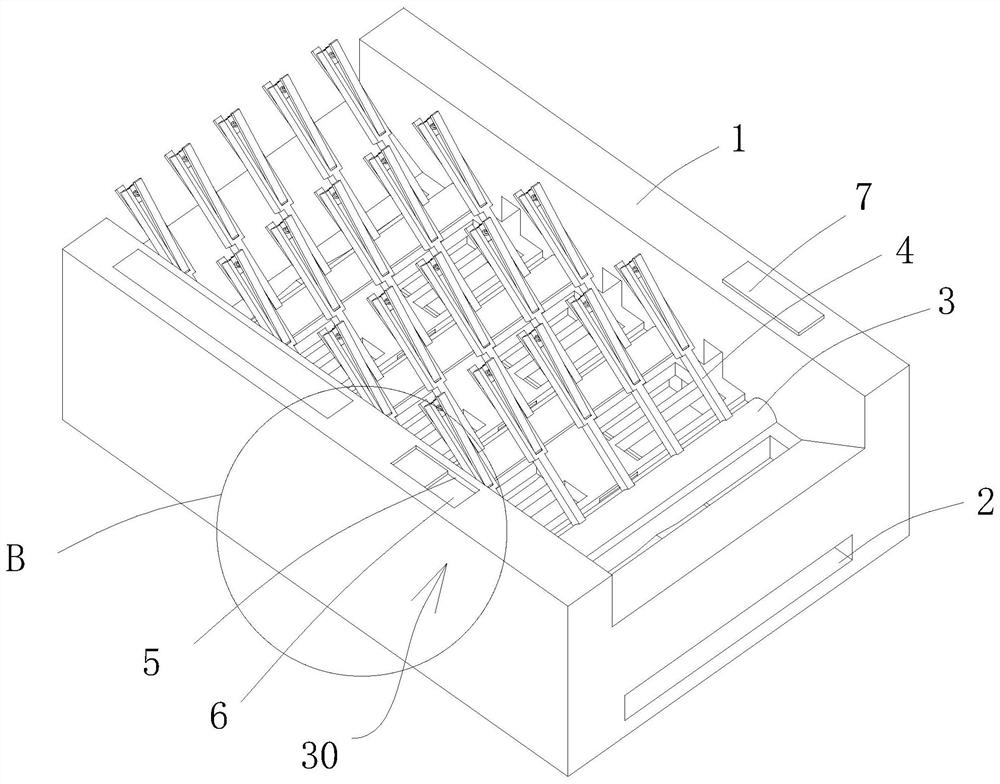

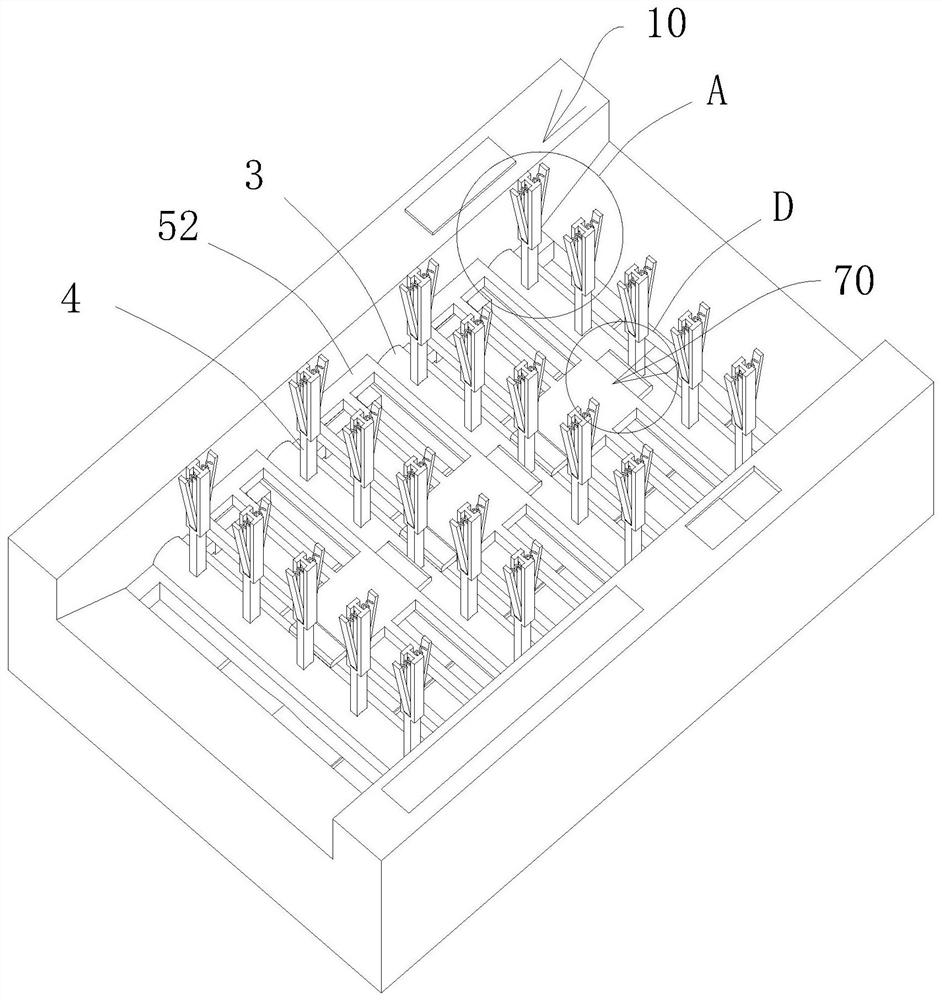

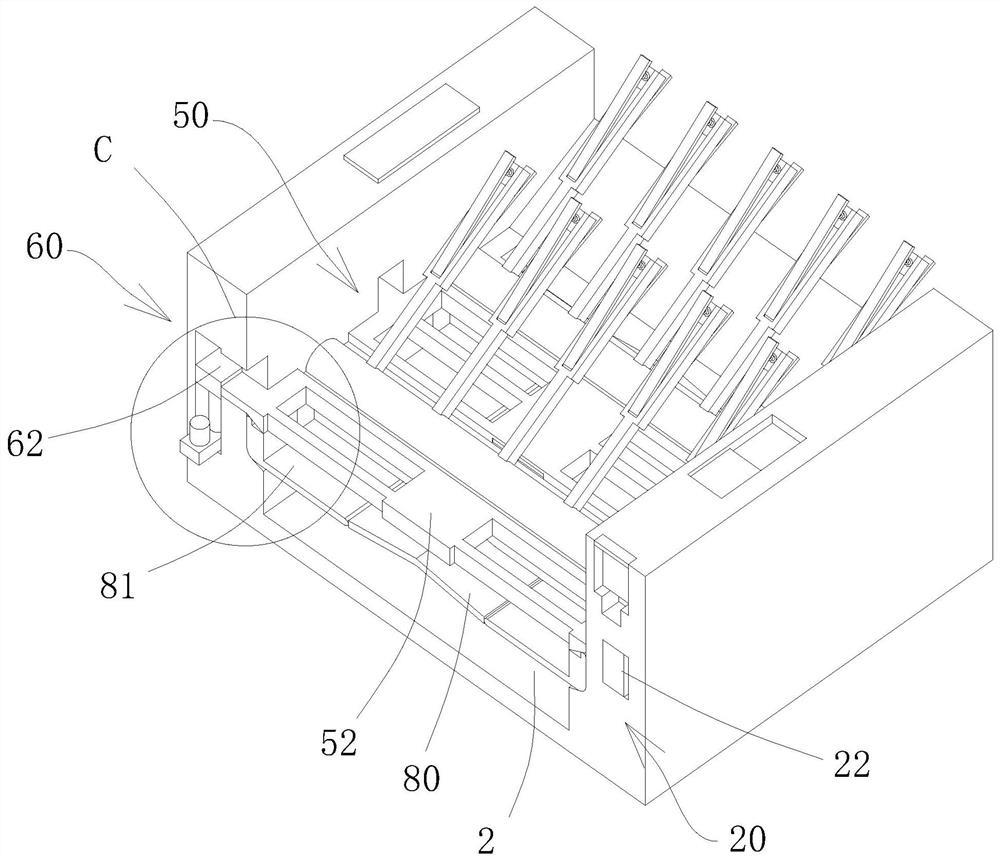

[0036] A kind of Ganoderma lucidum drying equipment, such as Figure 1 to Figure 3 As shown, it includes a frame 1, the lower end of the frame 1 is provided with a collection chamber 2, and the middle of the frame 1 is connected with three uniformly distributed main rods 3 through bearing rotation, and the main rod 3 is embedded with five uniformly distributed struts 4 Ganoderma lucidum is placed between the adjacent poles 4 on the left and right sides, the top of the poles 4 is provided with a flexible clamping mechanism 10 that contacts the cap of the Ganoderma lucidum, and the frame 1 is provided with a power mechanism 20 that drives the main pole 3 to turn over. The front end of the frame 1 is provided with a water storage tank 5, and the water storage tank 5 is provided with a water-absorbing sponge 6. The frame 1 is provided with a pressure sensing mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com