Connector with improved air tightness

A connector and air-tightness technology, applied in the direction of connection, two-part connection device, and parts of the connection device, can solve the problems of insufficient air-tightness, heat generation, moisture and moisture, etc., and extend the path of gas passage. , The effect of reducing the air gap area and improving the air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

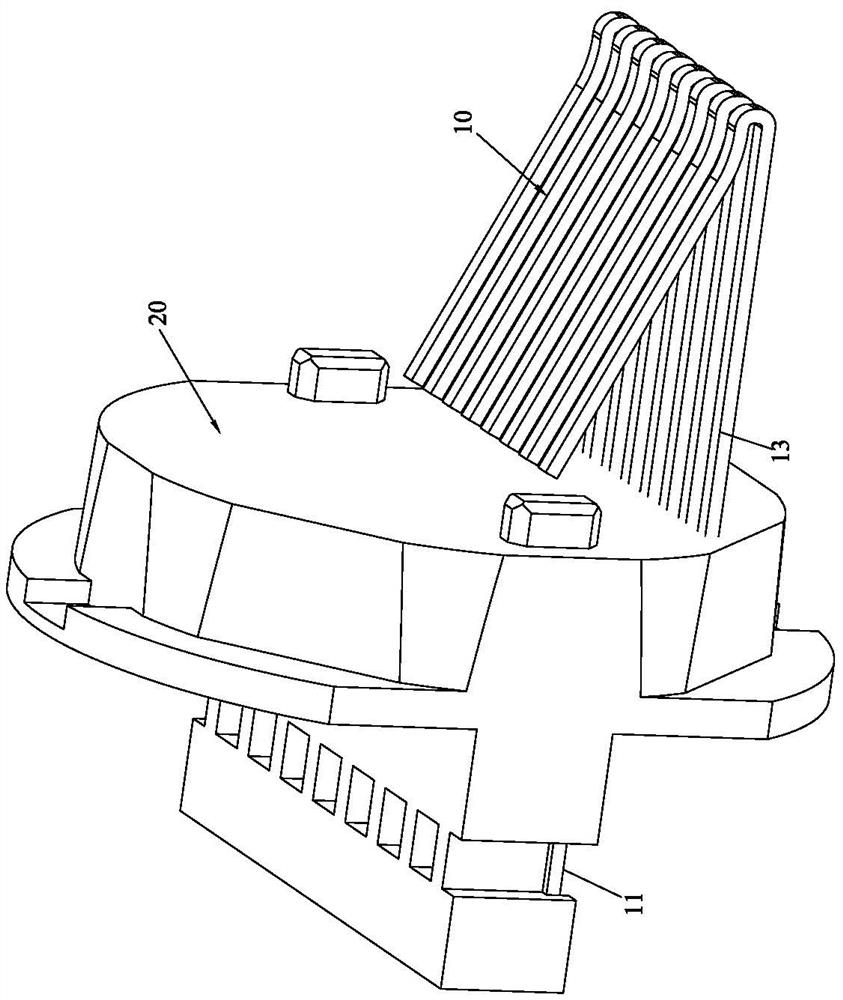

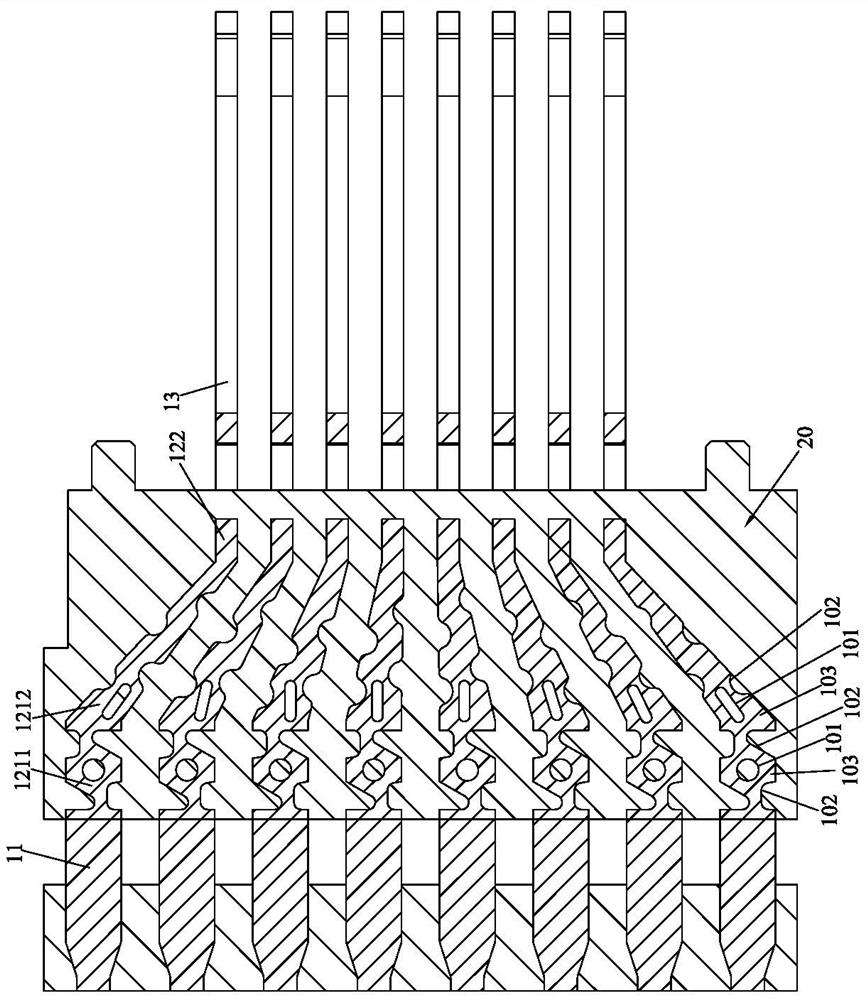

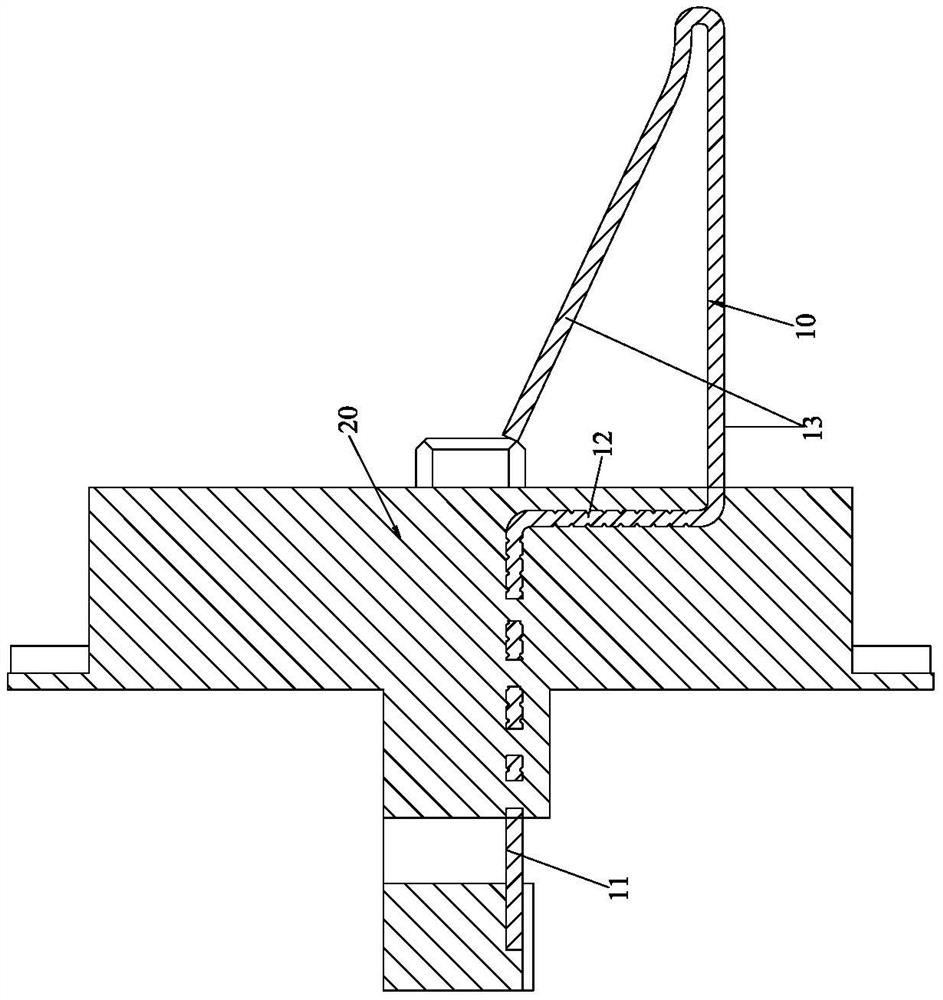

[0036] Please refer to Figure 1 to Figure 6 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a terminal group 10 and a terminal seat 20 integrally injection molded outside the terminal group 10, each terminal in the terminal group 10 includes The solder leg part 11, the fixed part 12, and the contact part 13 are connected in sequence. The solder leg part 11 protrudes backward from the terminal base 20, the fixed part 12 is buried in the terminal base 20, and the contact part 13 is forward extending out of the terminal block 20;

[0037] The fixing part 12 is provided with a through hole 101 penetrating through the upper surface and the lower surface of the fixing part 12, and the left side and the right side of the fixing part 12 are provided with a plurality of recesses arranged at intervals along the extending direction of the fixing part 12. 102, a protrusion 103 is formed between adjacent concave positions 102; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com