Juicer squeezing assembly

A juicer and component technology, which is applied in the field of juicer pressing components to achieve smooth slag discharge process, convenient loading and unloading, improving effect and juice quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

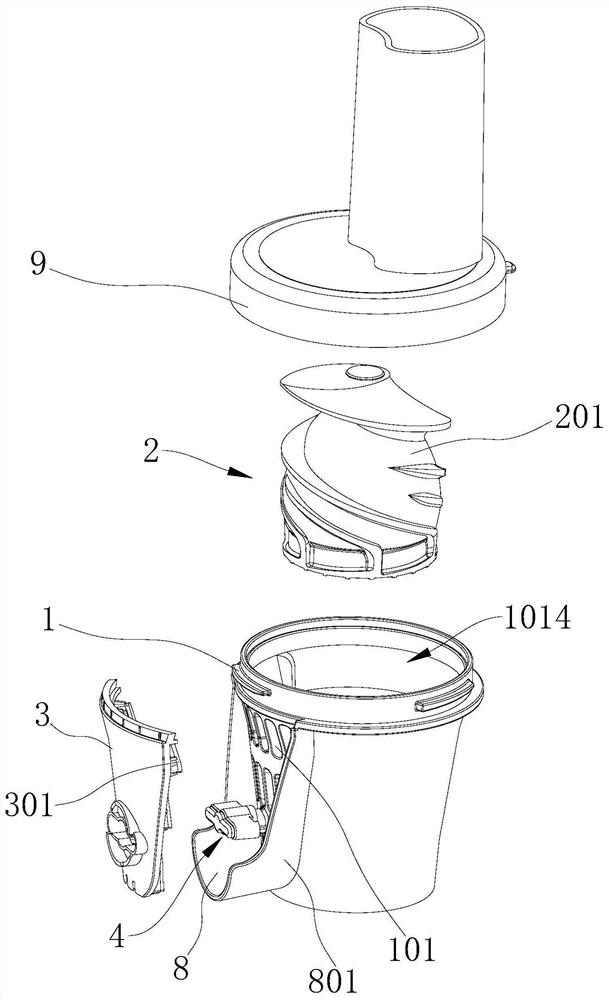

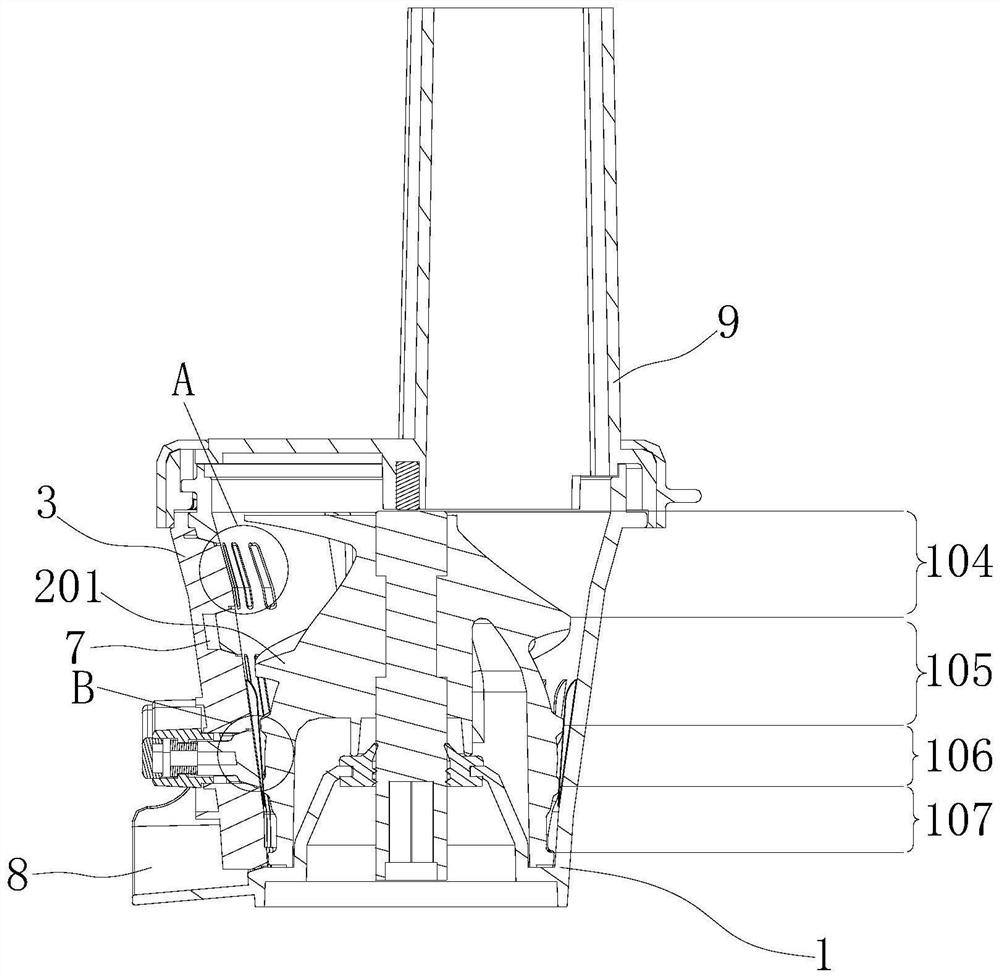

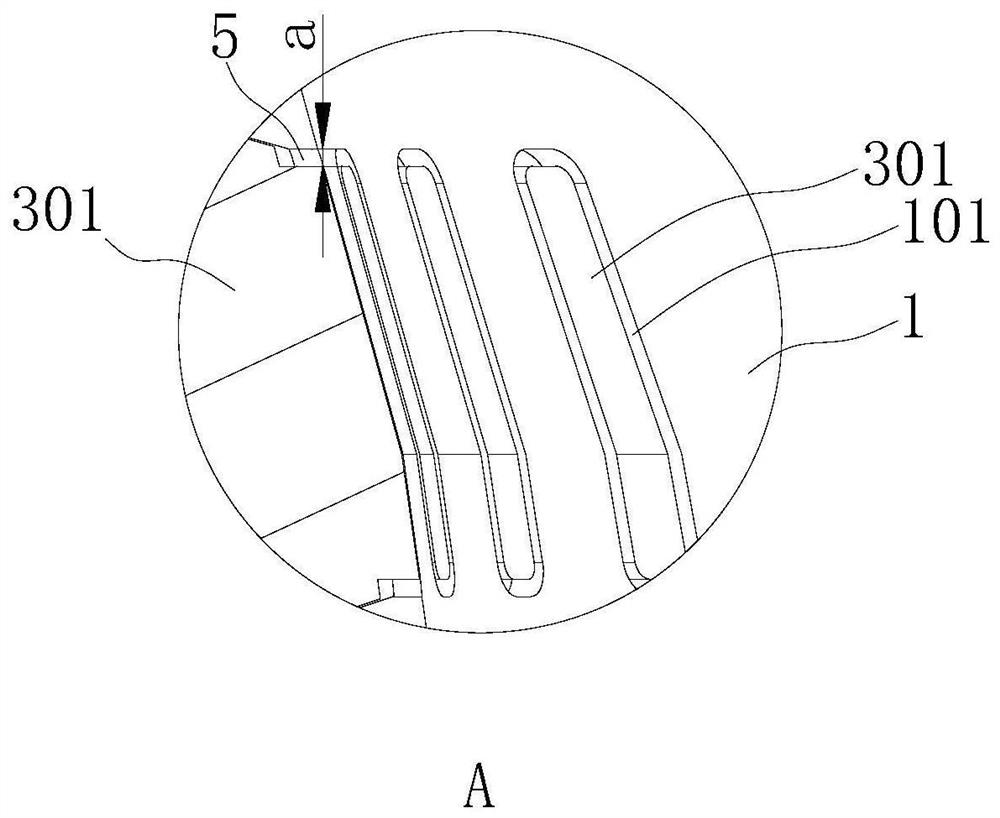

[0059] refer to Figure 1-18 , the present invention discloses a juicer pressing assembly, comprising: a juicer cup 1, a plurality of filter through holes 101 are provided through the wall of the juicer cup 1; a grinding assembly 2 arranged in the juicer cup 1; The filter baffle 3 on the outer wall 1013 of the juicer cup 1, the side of the filter baffle 3 facing the juicer cup 1 is provided with ribs 301; and the locking mechanism for locking the filter baffle 3 to the juicer cup 1 4; Wherein, the raised rib 301 is set corresponding to the filter through hole 101, and the raised rib 301 can be inserted into the filter through hole 101, so that the circumferential direction of the raised rib 301 and the inner wall 10104 of the filter through hole 101 form a gap for the juice to flow through. The filter gap 5 forms a filter structure.

[0060] Thus, by installing the filter baffle 3 on the outside of the juice cup 1 and fixing it by the locking mechanism 4, the ribs 301 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com