Rice production line

A production line and rice technology, applied in the directions of sound-producing equipment, pollution prevention methods, and sieves, etc., can solve the problems of unreasonable layout, large noise, and large floor space, and achieve the goal of ensuring processing quality, keeping quiet, and isolating noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

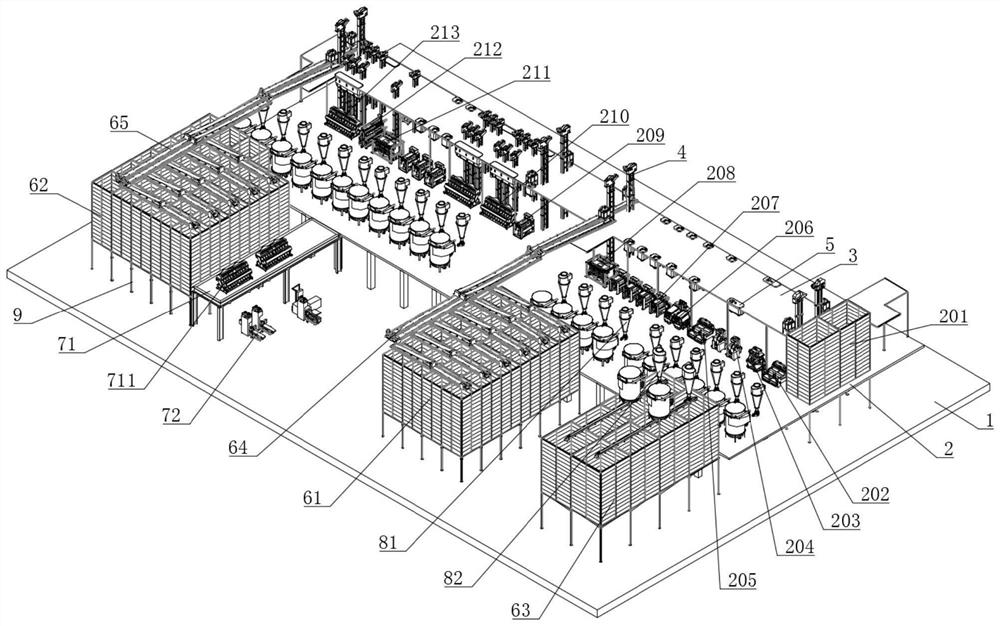

[0014] figure 1 Schematic diagram of the embodiment of the rice production line provided by the present invention, including an overhead layer 1, a processing layer 2, and a conveying layer 3 arranged sequentially from bottom to top, and the processing layer 2 is provided with rice barn equipment 201 and plane gyratory cleaning equipment in sequence according to the production sequence Ⅰ202, stone removing equipment 203, pneumatic hulling equipment 204, plane gyratory cleaning equipment Ⅱ205, gravity rice paddy separation equipment 206, double-roller wind jet rice milling equipment 207, sieving equipment Ⅰ208, polishing equipment 209, color sorting equipment Ⅰ210, sorting equipment Sieve equipment II 211, drum selection equipment 212, and color sorting equipment II 213. The discharge port of each device is connected to the conveying layer 3 through the lifting device 4, and the feed port of each device is connected to the conveying layer 3 through the hopper 5. Layer 1 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com