Ceramic product production device

A technology for producing devices and ceramic products, applied in ceramic molding machines, manufacturing tools, auxiliary molding equipment, etc., can solve the problems of inability to adjust the liquid concentration on the surface of the clay, and achieve the effects of convenient operation, improved smoothness, and improved flatness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

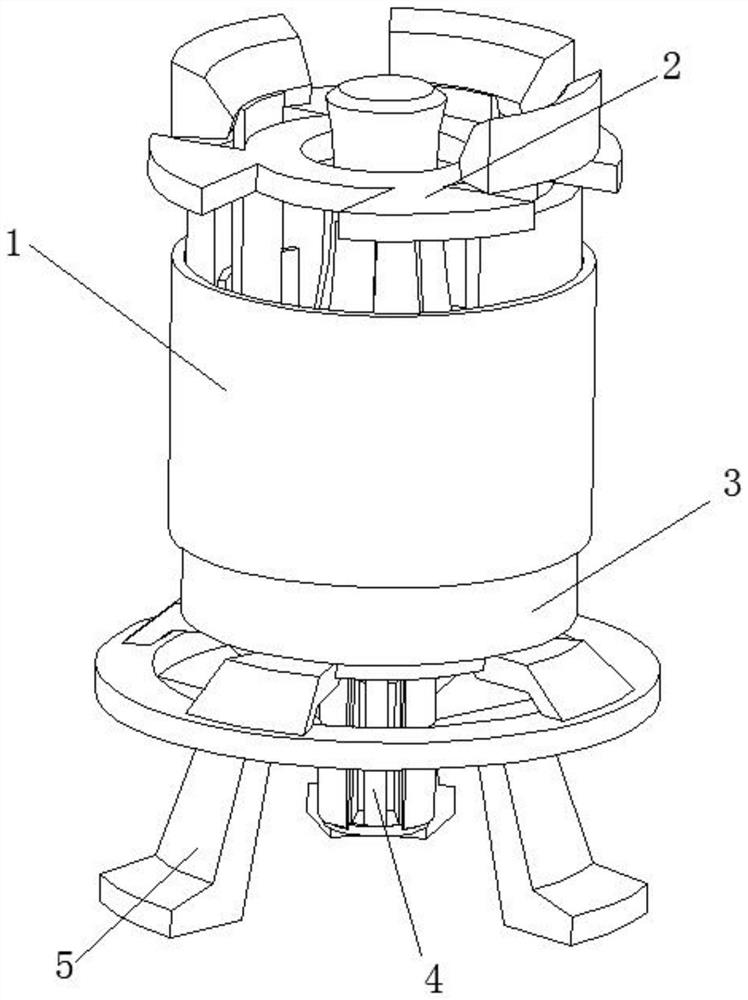

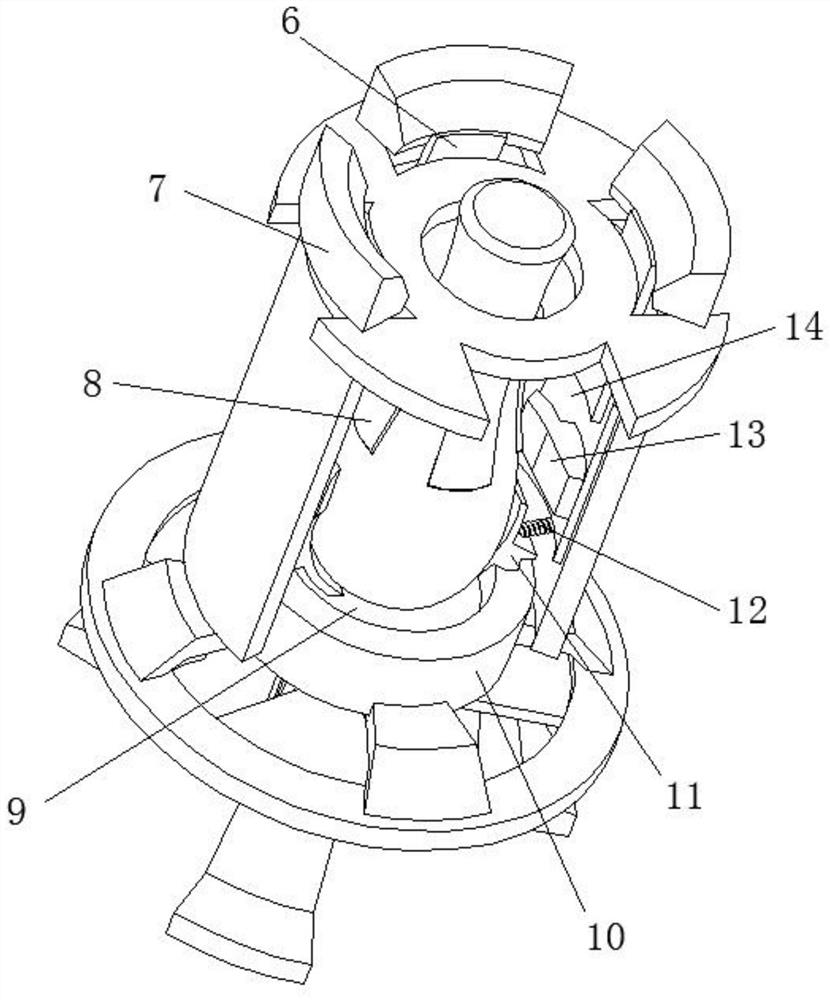

[0033] Such as Figure 1-2 As shown, the present invention provides a technical solution: a device for producing ceramic products, including an operation case 3, the bottom of the operation case 3 is fixedly connected with a support base 5, and the outer surface of the operation case 3 is sleeved with Sliding housing 1, a rotating motor 4 is fixedly connected to the middle of the bottom of the supporting base 5, and is characterized in that: the output end of the rotating motor 4 is fixedly connected to a rotating base plate 9, and the outer surface of the rotating base plate 9 is sleeved with The socket bottom ring 10, the outer surface of the socket bottom ring 10 is sleeved at the inner cavity of the operation case 3, the bottom of the socket bottom ring 10 is fixedly connected to the top of the support base 5, the socket bottom A fitting block 11 is fixedly connected to the top of the ring 10;

[0034] The outer surface of the fitting block 11 is fixedly connected with a ...

Embodiment 2

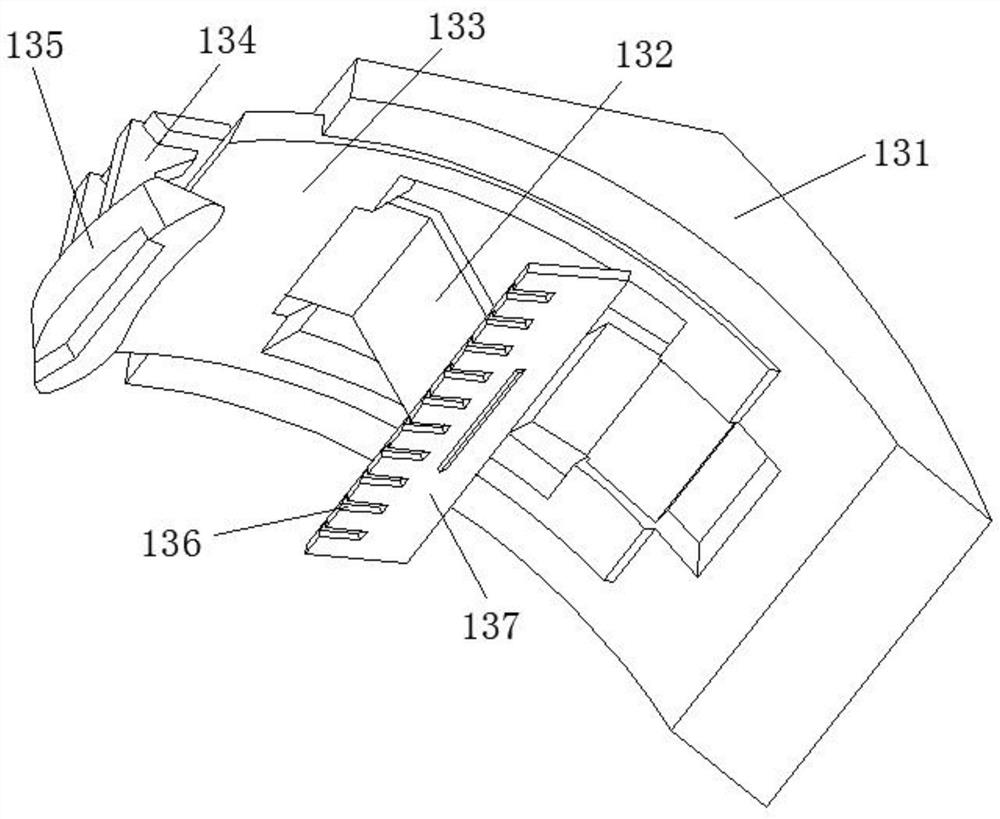

[0040] Such as Figure 3-5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the surface treatment device 13 includes a treatment scraper 131, the surface of the treatment scraper 131 is fixedly connected to the inner surface of the slide 14, The front of the processing scraper 131 is fixedly connected with an inner contact plate 133, and the inside of the inner contact plate 133 is provided with a convex folded plate 132, and the end of the convex folded plate 132 is fixedly connected to the surface of the inner contact plate 133. place.

[0041] The side of the convex fold plate 132 away from the inner contact plate 133 is fixedly connected with a transmission rod 134, the end of the transmission rod 134 is fixedly connected with a concentration processing device 135, and the bend of the convex fold plate 132 is fixedly connected with a A lamination plate 137 , a coarse filter scraper groove 136 is fixedly connected to the surface ...

Embodiment 3

[0050] Such as Figure 6 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the feeding device 8 includes a feeding convex bucket 81, and the outer surface of the feeding convex bucket 81 is fixedly connected with a fixed Block 82, the inside of the fixed block 82 is provided with a feeding hole 84, the inner wall of the feeding convex bucket 81 is fixedly connected with a one-way feeding buckle 85, and the inner cavity surface of the feeding convex bucket 81 is covered An outer support plate 83 is provided. In the process of feeding into the feeding convex bucket 81, the outer support plate 83 can be pressurized and formed on the outside when the internal material increases, and the energy-saving effect of the device can be improved by using its own gravity; at the same time, when the material increases, the feeding hole 84 will squeeze out Materials are processed to prevent excessive waste of materials.

[0051] Pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com