Connecting structure for binding belt and hook

A technology of connecting structure and binding belt, applied in the field of connecting structure between binding belt and hook, can solve the problems of unable to replace the hook, unable to replace the hook, increase the user's input cost, etc., to achieve a large market promotion prospect, low manufacturing cost, practical strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

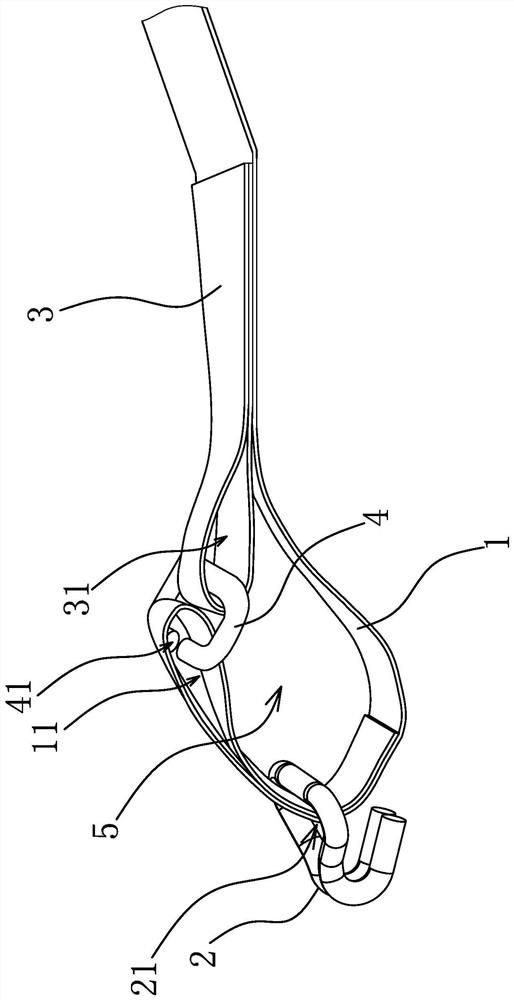

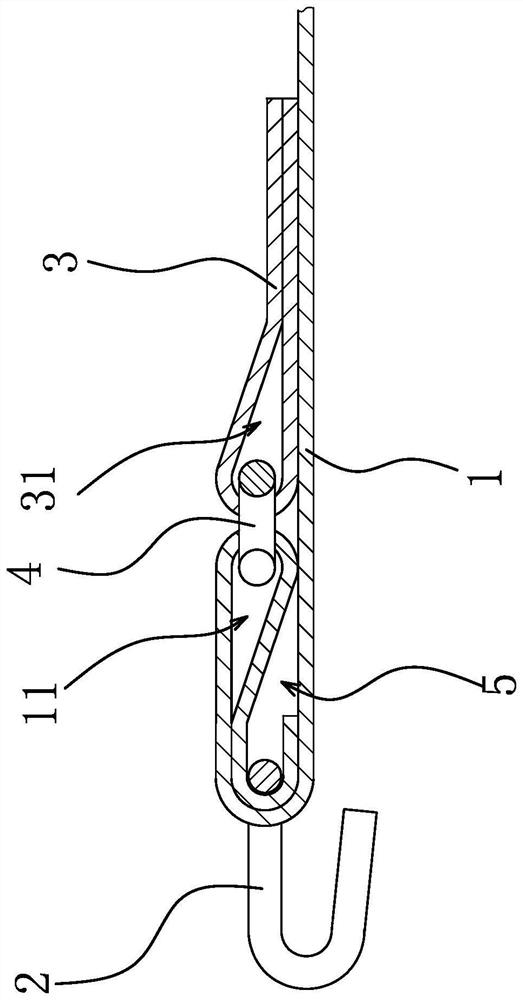

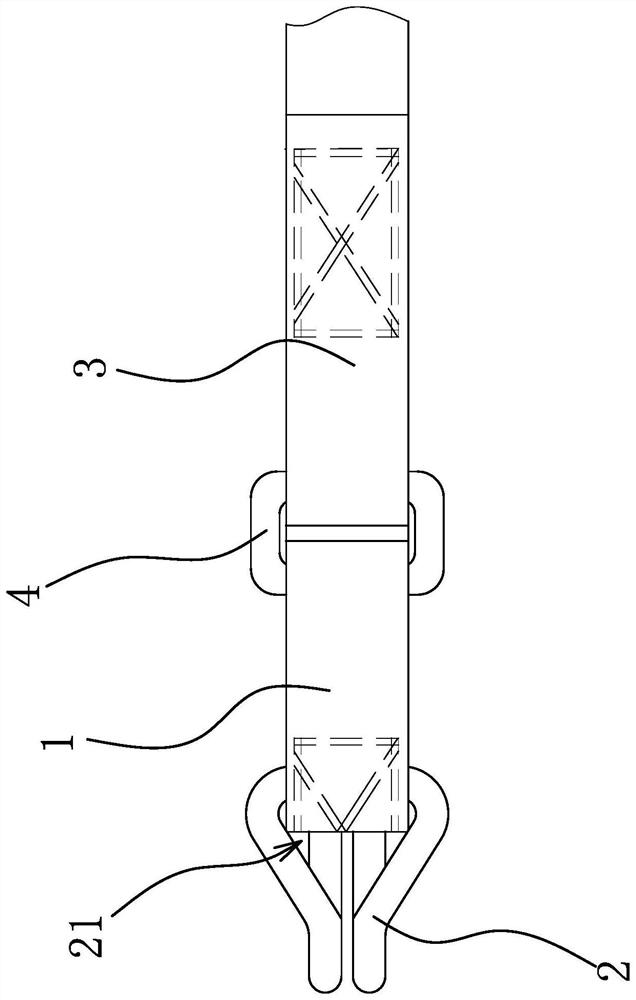

[0038] Such as Figure 1 to Figure 3 As shown, the connection structure between the binding belt and the hook includes a main belt body 1, an auxiliary belt body 3 and a hook 2, the end of the main belt body 1 has a closed socket ring 11, and the auxiliary belt body 3 is fixedly connected to the main belt body 1, the end of the auxiliary belt body 3 also has a closed sleeve ring 2 31, and the sleeve ring 11 and the sleeve ring 2 31 are connected through a connecting ring 4 with a gap 41, thereby forming a large ring 5 , the hook 2 is threaded on the large ring 5 .

[0039] Specifically, continue to refer to Figure 1 to Figure 3 After the end of the main belt body 1 is folded in half along the length direction, the folded part is partially sewed to form the above-mentioned sleeve ring 11, and the binding belt is tightened by the hook 2 to form the suture of the hook 2 and the end of the main belt body 1 when tensioned. Part contact, because the suture part is a double-layer ...

Embodiment 2

[0043] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: Figure 9 As shown, the connecting ring 4 is an integrally formed circular metal ring. The connecting ring 4 is an integrally formed circular metal ring, which is more convenient to manufacture and can reduce manufacturing costs. At the same time, the connecting ring 4 has a relatively high tensile strength due to the integral forming, and is not easily deformed during the binding process.

Embodiment 3

[0045] The structure and principle of this embodiment are basically the same as that of the first embodiment, except that the length of the inner hole of the connecting ring 4 is equal to the width of the main belt body 1 and the auxiliary belt body 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com