Production process of feed-grade copper glutamate

A production technology of copper glutamate, which is applied in the field of production technology of feed grade copper glutamate, can solve problems such as being difficult to apply to actual production, and achieve the effects of low equipment cost, environmentally friendly process, and simple post-treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

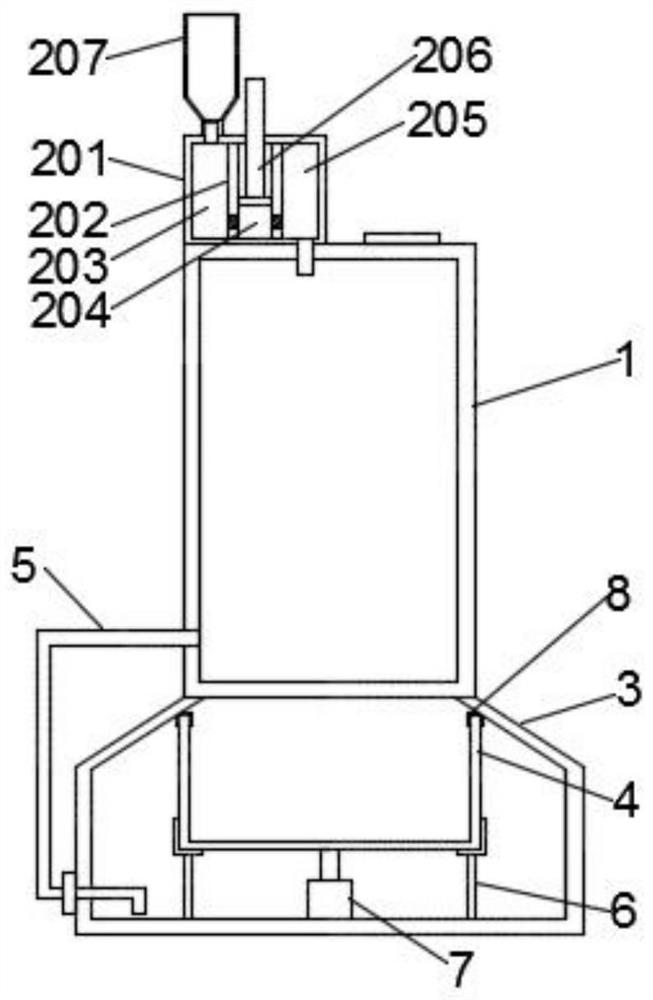

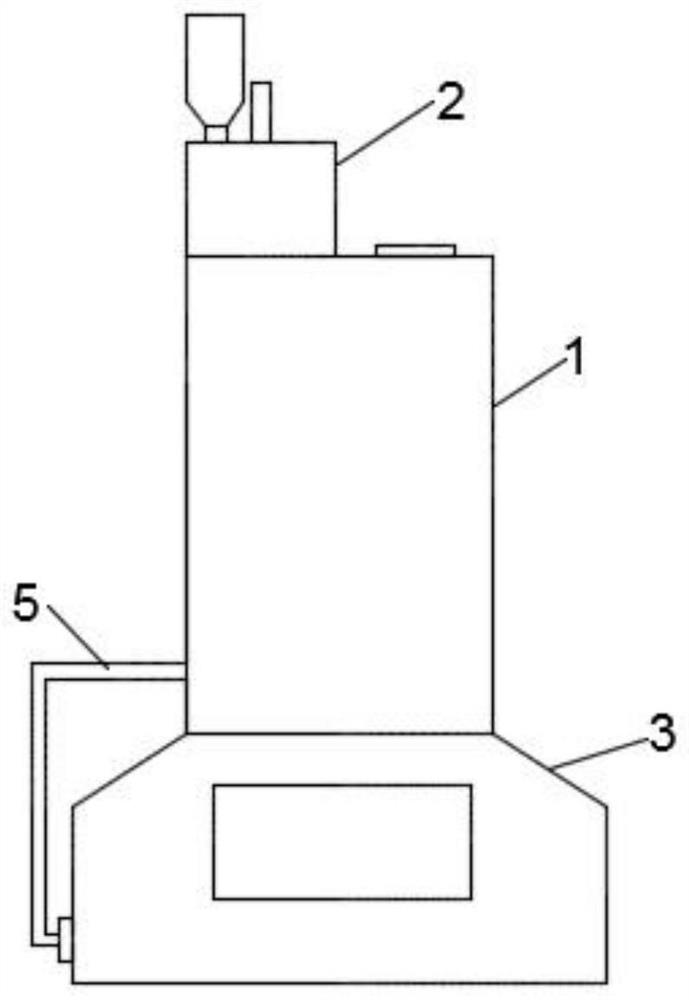

[0025] see Figure 1-2 :

[0026] (1) Add deionized water and feed grade glutamic acid in reactor 1;

[0027] (2) Make the piston 206 move up in the buffer chamber 204, at this time the pressure valve on the side of the feed chamber 203 is opened, the pressure valve on the side of the discharge chamber 205 is closed, and the copper sulfate in the feed chamber 207 enters the buffer along the feed chamber 203 chamber 204, move up the piston 206, at this time the pressure valve on the side of the feeding chamber 203 is opened and closed, the pressure valve on the side of the discharging chamber 205 is opened, and the copper sulfate is output to the reactor 1 along the discharging chamber 205, driven by an electric telescopic rod Piston 206, control the moving speed of piston 206 to 2mm / s, the molar ratio of total copper content to glutamic acid is 1:1, stir in reaction kettle 1 and heat up to 55°C;

[0028] (3) continue to heat up, control reaction temperature 75 ℃, keep warm f...

Embodiment 2

[0032] see Figure 1-2 :

[0033] (1) Add deionized water and feed grade glutamic acid in reactor 1;

[0034](2) Make the piston 206 move up in the buffer chamber 204, at this time the pressure valve on the side of the feed chamber 203 is opened, the pressure valve on the side of the discharge chamber 205 is closed, and the copper sulfate in the feed chamber 207 enters the buffer along the feed chamber 203 chamber 204, move up the piston 206, at this time the pressure valve on the side of the feeding chamber 203 is opened and closed, the pressure valve on the side of the discharging chamber 205 is opened, and the copper sulfate is output to the reactor 1 along the discharging chamber 205, driven by an electric telescopic rod Piston 206, control the moving speed of piston 206 to 2mm / s, the molar ratio of total copper content to glutamic acid is 1:1, stir in reaction kettle 1 and heat up to 60°C;

[0035] (3) continue to heat up, control reaction temperature 80 ℃, keep warm fo...

Embodiment 3

[0039] see Figure 1-2 :

[0040] (1) Add deionized water and feed grade glutamic acid in reactor 1;

[0041] (2) Make the piston 206 move up in the buffer chamber 204, at this time the pressure valve on the side of the feed chamber 203 is opened, the pressure valve on the side of the discharge chamber 205 is closed, and the copper sulfate in the feed chamber 207 enters the buffer along the feed chamber 203 chamber 204, move up the piston 206, at this time the pressure valve on the side of the feeding chamber 203 is opened and closed, the pressure valve on the side of the discharging chamber 205 is opened, and the copper sulfate is output to the reactor 1 along the discharging chamber 205, driven by an electric telescopic rod Piston 206, control the moving speed of piston 206 to 2mm / s, the molar ratio of total copper content to glutamic acid is 1:1, stir in reaction kettle 1 and heat up to 65°C;

[0042] (3) continue to heat up, control reaction temperature 85 ℃, keep warm f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com