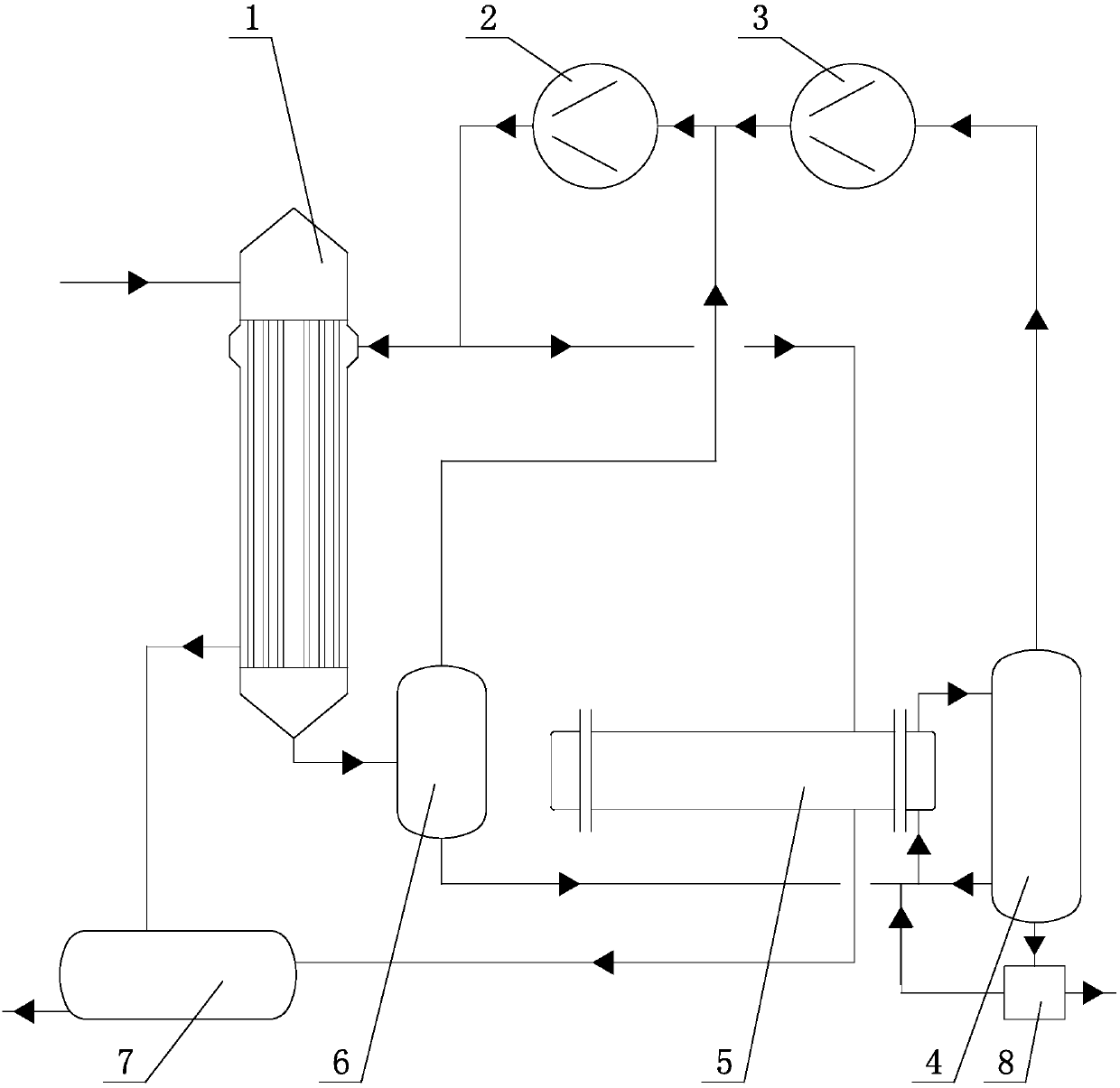

Double-stage MVR evaporation and crystallization process and equipment

An evaporation crystallization and two-stage evaporation technology, which is applied in the direction of evaporation, multi-effect evaporation, evaporator accessories, etc., can solve the problems of large investment in production technology equipment, complicated process operation and control, and high energy consumption of the process, and achieve simplified process operation and Effect of controlling, reducing process energy consumption and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] The raw material liquid contains 32%wt of dimethyl sulfoxide and 15%wt of sodium nitrate, which is subjected to desalination treatment, and the dimethyl sulfoxide therein is recovered and reused. The raw material liquid is input into the primary evaporator 1 through the raw material pipeline (processing capacity 1500kg / h), the temperature of the raw material liquid is 57°C, and the operating parameters of the primary separation chamber 6 are: evaporation pressure 7kPa, evaporation temperature 98°C; secondary separation chamber 4 The operating parameters are: evaporation pressure 3kPa, evaporation temperature 98°C. In this embodiment, what is collected by the condensate storage tank 7 is the dimethyl sulfoxide product that needs to be recovered after desalination.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com