Tin-containing sludge treatment method

A treatment method and sludge technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve problems such as complex treatment process, high energy consumption, equipment corrosion, etc. Achieve the effect of simple process and low process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

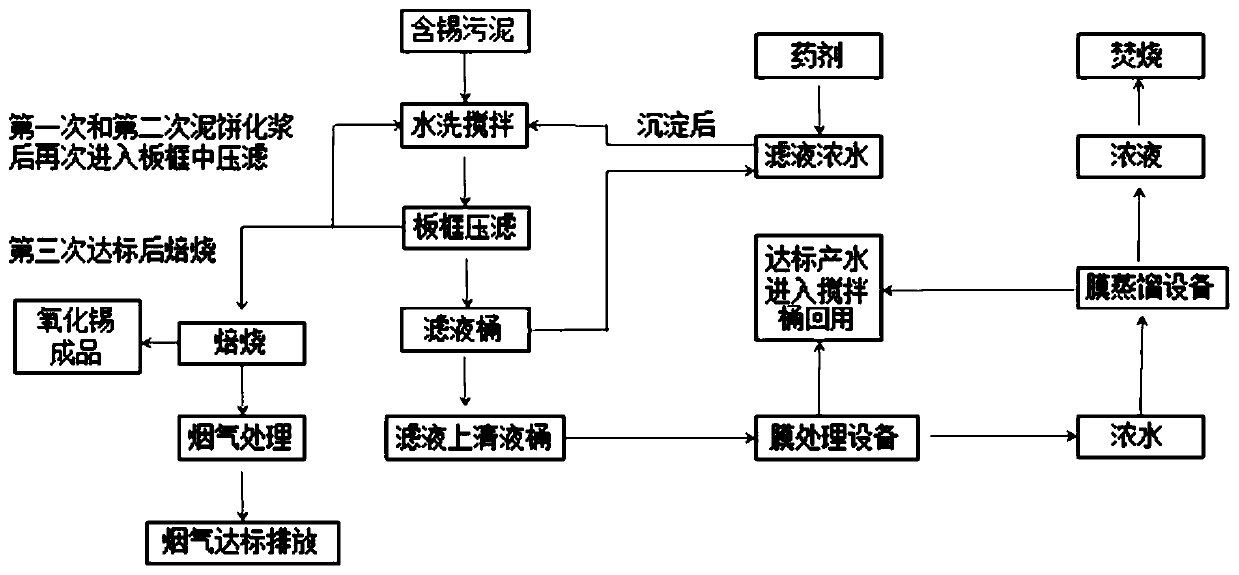

[0030] This embodiment relates to a treatment method of tin-containing sludge, such as figure 1 shown, including the following steps:

[0031] 1. The electroplating solution prepared with PSA as the solution is tested and analyzed on the tin-containing sludge after the electroplating production line. The detected pH value is 1-2, and the COD content is 3.5×10 4 mg / l, the moisture content is 50-65%, and the production line process parameters are adjusted to the parameters suitable for the production of this material;

[0032] 2. Mix tin-containing sludge and pure water, stir in a mixing tank for 30 minutes, and prepare a slurry with a solid content of 1-20%;

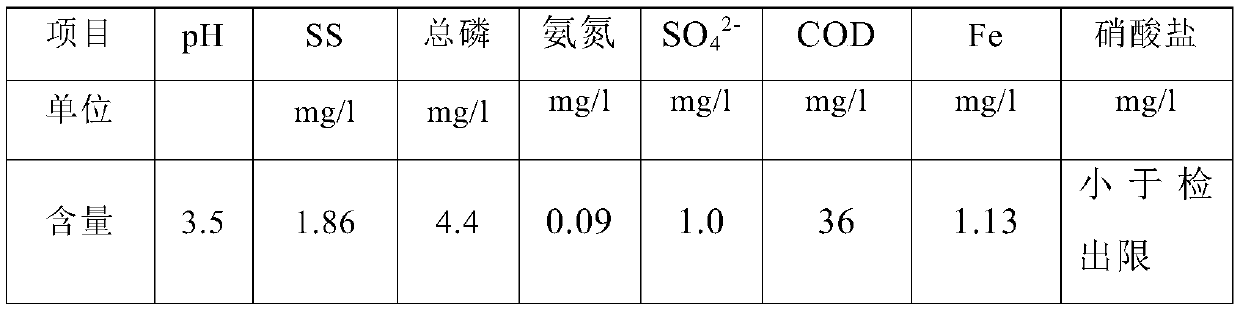

[0033] 3. Put the mud into the plate and frame filter press through the material pump, and separate it into filtrate and solid phase, wherein, the content of each component in the solid phase is shown in Table 3;

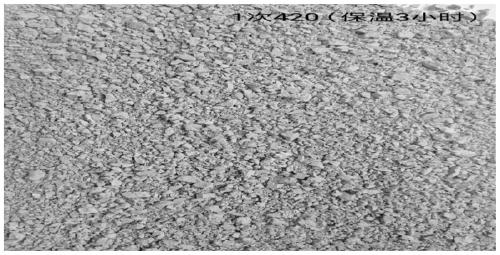

[0034] 4. Heat treatment at 300-650°C after the solid phase is collected to obtain a tin oxide product, wh...

Embodiment 2

[0038] This embodiment relates to a treatment method for tin-containing sludge, comprising the steps of:

[0039] 1. The electroplating solution prepared with sulfuric acid is tested and analyzed on the tin-containing sludge after the electroplating production line. The detected pH value is 1-2, and the moisture content is 50-65%. Adjust the process parameters of the production line to be suitable for this material production parameters;

[0040] 2. Mix the tin-containing sludge and pure water into slurry according to a certain weight ratio, and stir in the mixing tank for 30 minutes;

[0041] 3. Put the mud into the solid-liquid separation equipment through the material pump, and separate it into filtrate and solid phase, wherein the contents of each component in the solid phase are shown in Table 3;

[0042] 4. Heat treatment at 300-650°C after the solid phase is collected to obtain tin oxide products, which are packaged and put into storage;

[0043] 5. After the filtrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com