Novel green lithium iron phosphate precursor as well as preparation method and application thereof

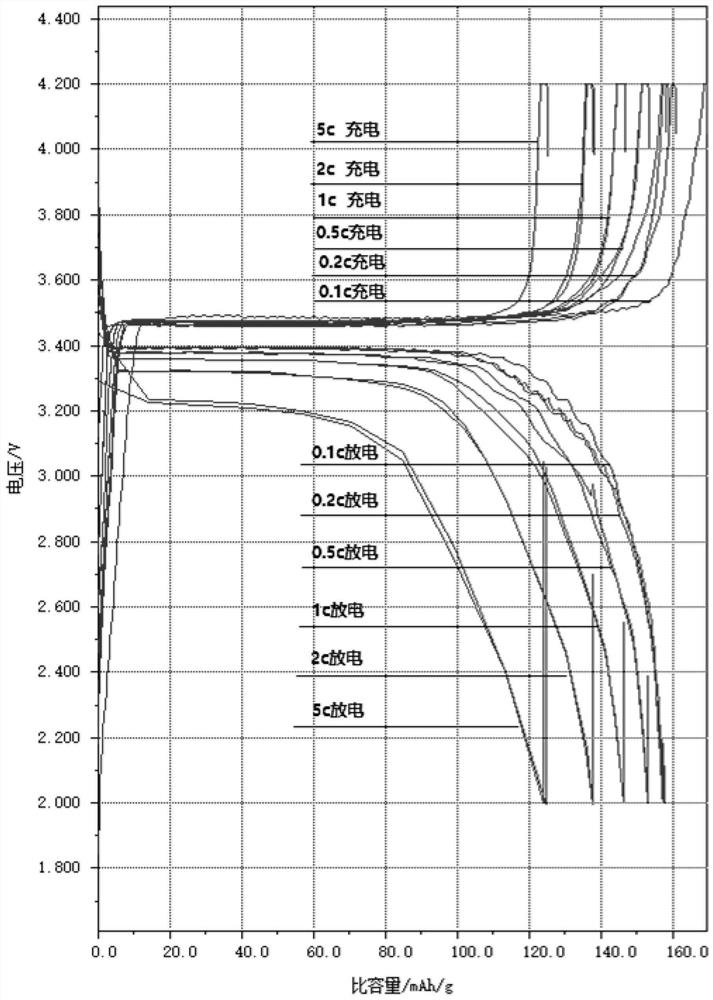

A lithium iron phosphate and precursor technology, which is applied in the field of new green lithium iron phosphate precursor and its preparation, can solve the problems that the solid content of lithium iron phosphate is difficult to control, the viscosity cannot be stirred, and the process cost is high, and the solid content can be improved. , low cost, high charge and discharge rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] (1) According to the molar ratio of iron element to phosphorus element is 0.96:1, add 6.895kg of 85% industrial grade phosphoric acid into 5L deionized water and stir to dilute to 49% concentration, slowly add 3.25kg of 200 mesh, The secondary reduced iron powder with a purity of 99% is reacted at 45°C, some gas will be generated during the reaction, and the color of the reactant will gradually change from gray black to gray white. When there is no gas generated in the reaction, put the material into the sand mill for sand grinding. The grinding beads in the sand mill are 0.3mm zirconia beads. During the sand grinding process, the viscosity gradually increases to 15000cps, and the color gradually becomes pure white. , to obtain product A.

[0062] 2. According to the molar ratio of lithium and phosphorus elements of 1.04:1, dissolve 4kg of citric acid in 3.25kg of deionized water to make a solution, and gradually add 2.3kg of battery-grade lithium carbonate and 1kg of s...

Embodiment 2

[0069] 1. According to the molar ratio of iron element to phosphorus element is 0.98:1, add 13.8kg of 85% food-grade phosphoric acid into 5L deionized water and stir to dilute to 62.4% concentration, slowly add 6.6kg of 250 mesh, purity 99.5% secondary reduced iron powder is reacted at 35°C, some gas will be generated during the reaction process, and the color of the reactant will gradually change from gray black to gray white. When there is no gas generated in the reaction, put the material into the sand mill for sand grinding. The grinding beads in the sand mill are 0.4mm zirconia beads. During the sand grinding process, the viscosity gradually increases to 20000cps, and the color gradually becomes pure white. Product A is obtained.

[0070] 2. According to the molar ratio of lithium and phosphorus elements of 1.03:1, dissolve 4kg of citric acid and 4kg of oxalic acid in 5kg of deionized water to make a solution, and mix 2kg of glucose and 5.18kg of industrial grade lithium ...

Embodiment 3

[0075] 1. According to the molar ratio of iron element to phosphorus element is 1:1, add 27.6kg of 85% food-grade phosphoric acid into 12L deionized water and stir to dilute the concentration to 59.2%. Slowly add 13.5kg of 300-mesh phosphoric acid with a purity of 99.7% while stirring. % electrolytic iron powder, react at 55°C, some gas will be generated during the reaction, and the color of the reactant will gradually change from gray black to gray white. When no gas is generated during the reaction, the material is put into a ball mill for ball milling. During the ball milling process, its viscosity gradually increases to 10,000 cps, and its color gradually turns into pure white to obtain product A.

[0076] 2. According to the molar ratio of lithium and phosphorus elements of 1.02:1, dissolve 6kg of malic acid and 7kg of tartaric acid in 5kg of deionized water to make a solution, and gradually mix 4kg of polyethylene glycol and 9.03kg of industrial grade lithium carbonate un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com