Method for producing ethanol through propagation fermentation of co-fermentation saccharomycetes

A yeast and ethanol production technology, applied in the direction of microorganism-based methods, fermentation, biochemical equipment and methods, etc., can solve the problems of low utilization efficiency of xylose and arabinose, low ethanol production rate, etc., and improve the utilization rate of equipment , increase ethanol yield, improve the effect of fermentation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0050] This preparation example is used to illustrate the preparation method of cellulose raw material enzymatic hydrolysis product

[0051] (1) Pretreatment of cellulose raw materials

[0052] Cut 1000 grams of impurity-free corn stalks (water content 10%) into small pieces not exceeding 1.2 cm x 0.5 cm x 1.0 cm, maintain a pressure of 1.70 MPa at 195 ° C for 5 minutes, and then release the pressure to complete steam explosion. Stir and mix the obtained steam explosion product with 70°C water at a mass ratio of 1:3 for 30 minutes, and then use a LW400 decanter centrifuge (Zhangjiagang Huada Centrifuge Manufacturing Co., Ltd.) to perform solid-liquid separation at a speed of 900 rpm , Obtain 3000 grams of water-washed steam explosion product (moisture content is 70% by weight) altogether.

[0053] (2) Enzymolysis

[0054] Add water in the enzymolysis tank, and under agitation, add the first batch of step (1) washed steam explosion product, the amount of the first batch of ad...

Embodiment 1

[0057] This embodiment is used to illustrate the method for ethanol production by yeast fermentation of the present invention

[0058] (1) activation

[0059] Yeast strain (S.C araABD) was activated with YEPX medium, and the activation conditions included: rotating speed 200 rpm, constant temperature shaker at 30°C, activation for 20 hours, to obtain an activation solution.

[0060] (2) Expansion training

[0061] The activation solution is inserted into the expansion tank equipped with primary expansion culture medium (yeast extract 10g / L, peptone 20g / L, glucose 20g / L) by 1.0% (V / V) and carries out expansion cultivation. 60% by volume, expansion conditions 30±1°C, pH 5.0±0.1 (adjusted by ammonia water), stirring speed 80-100rpm, no ventilation during the expansion process, expansion 12h, to obtain the primary expansion seed liquid.

[0062] The technical conditions and culture medium of the secondary expansion are the same as those of the primary, and the inoculum size is 2...

Embodiment 2

[0067] This embodiment is used to illustrate the method for ethanol production by yeast fermentation of the present invention

[0068] Carry out fermentation to produce ethanol according to the method described in Example 1, the difference is that sterile air is passed through during the primary expansion and secondary expansion, the ventilation rate is 0.05vvm, and the liquid filling volume is 65% by volume. The stirring speed is 60-80rpm.

[0069] After the secondary expansion, use an optical microscope to detect the number of yeast: 184 million / ml, budding rate: 18.3%, and mortality: 0.5%.

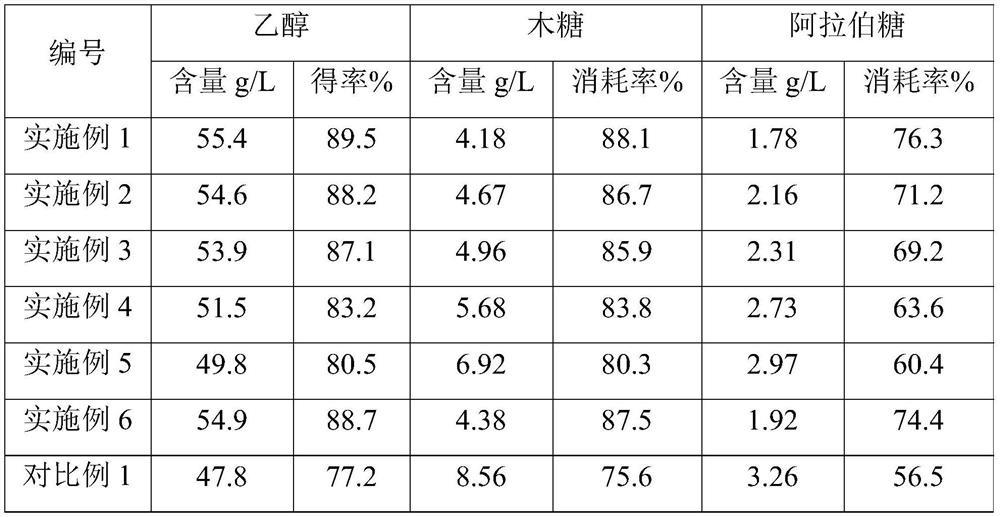

[0070] After the fermentation, the contents of ethanol, glucose, xylose and arabinose in the fermentation products were measured, and the ethanol yield, xylose consumption rate and arabinose consumption rate were calculated. The specific results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com