Filtration equipment

A technology of filtration equipment and filtration materials, applied in filtration and separation, membrane filters, gravity filters, etc., can solve problems such as small effective filtration surface area, and achieve the effect of improving work efficiency, reducing time, and reducing the number of backwash operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

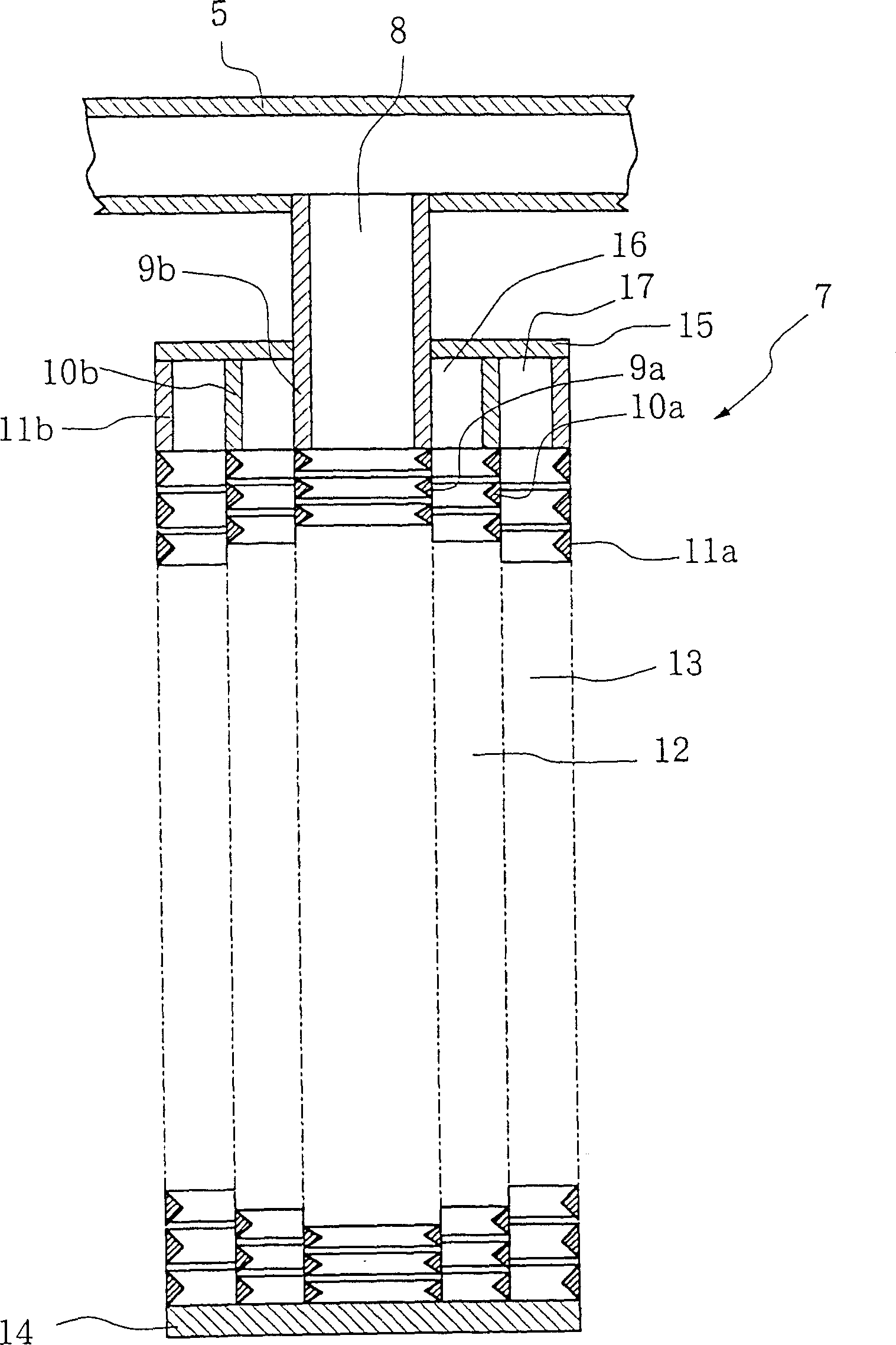

[0049] Figure 1-5 One embodiment of a filtration device manufactured according to the invention is described.

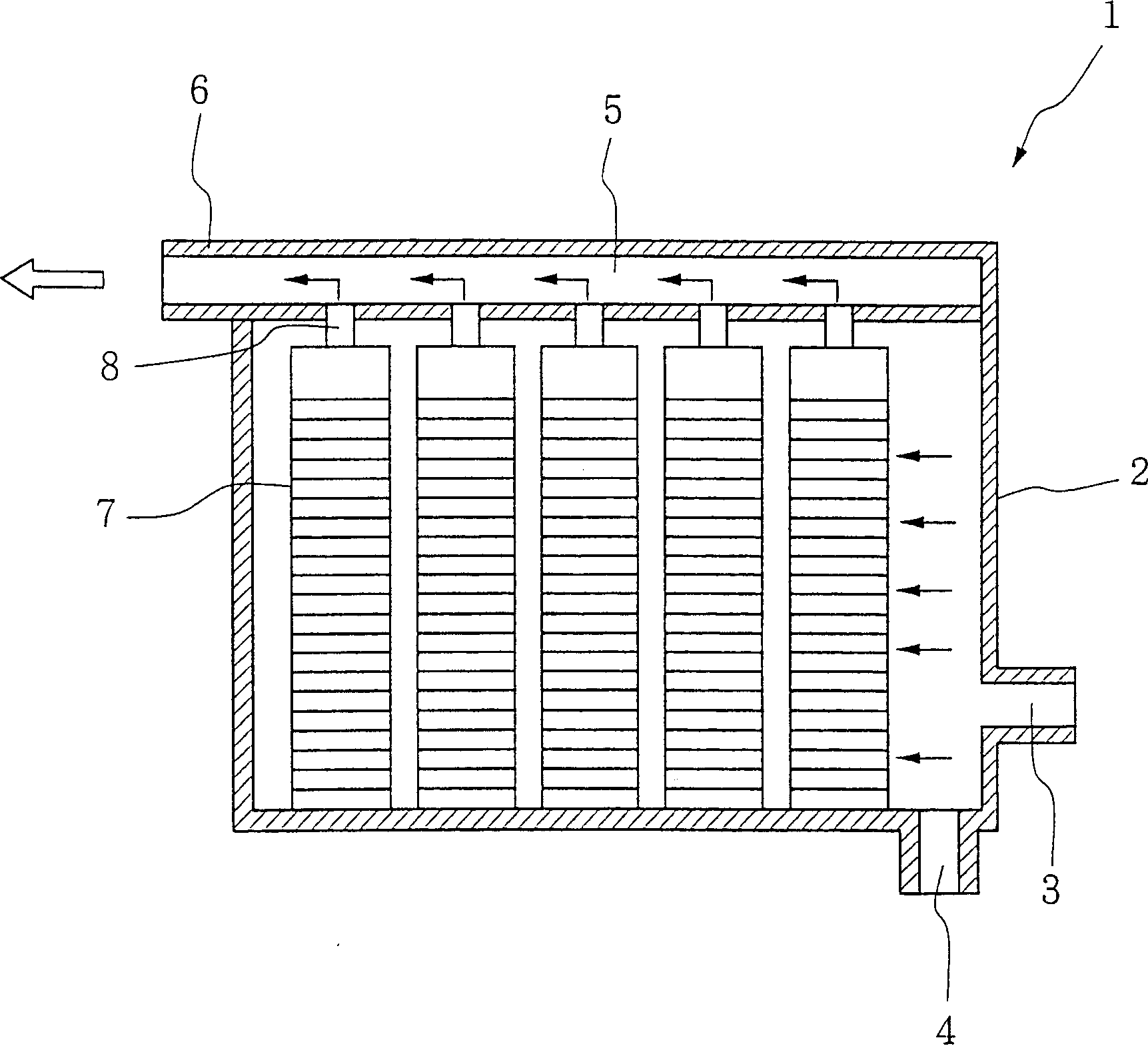

[0050] figure 1 The structure of the filter device 1 is schematically depicted. The container 2 is a box-like structure having a treatment liquid inlet 3 at the lower part of one side thereof and a discharge port 4 at the bottom thereof. The discharge port 4 is normally closed and is opened when solid foreign particles accumulated at the bottom of the container 2 are to be removed. The upper part of the container 2 is made as a process liquid discharge pipe 5 with an outlet 6 .

[0051] Within the container 2 are located one or more pre-filled annular multi-layer screen packs (five screen packs in the illustrated embodiment), which packs are identified by reference numeral 7 . Each screen assembly 7 has an outlet 8 at its upper portion, and the outlet 8 communicates with the treatment liquid discharge pipe 5 .

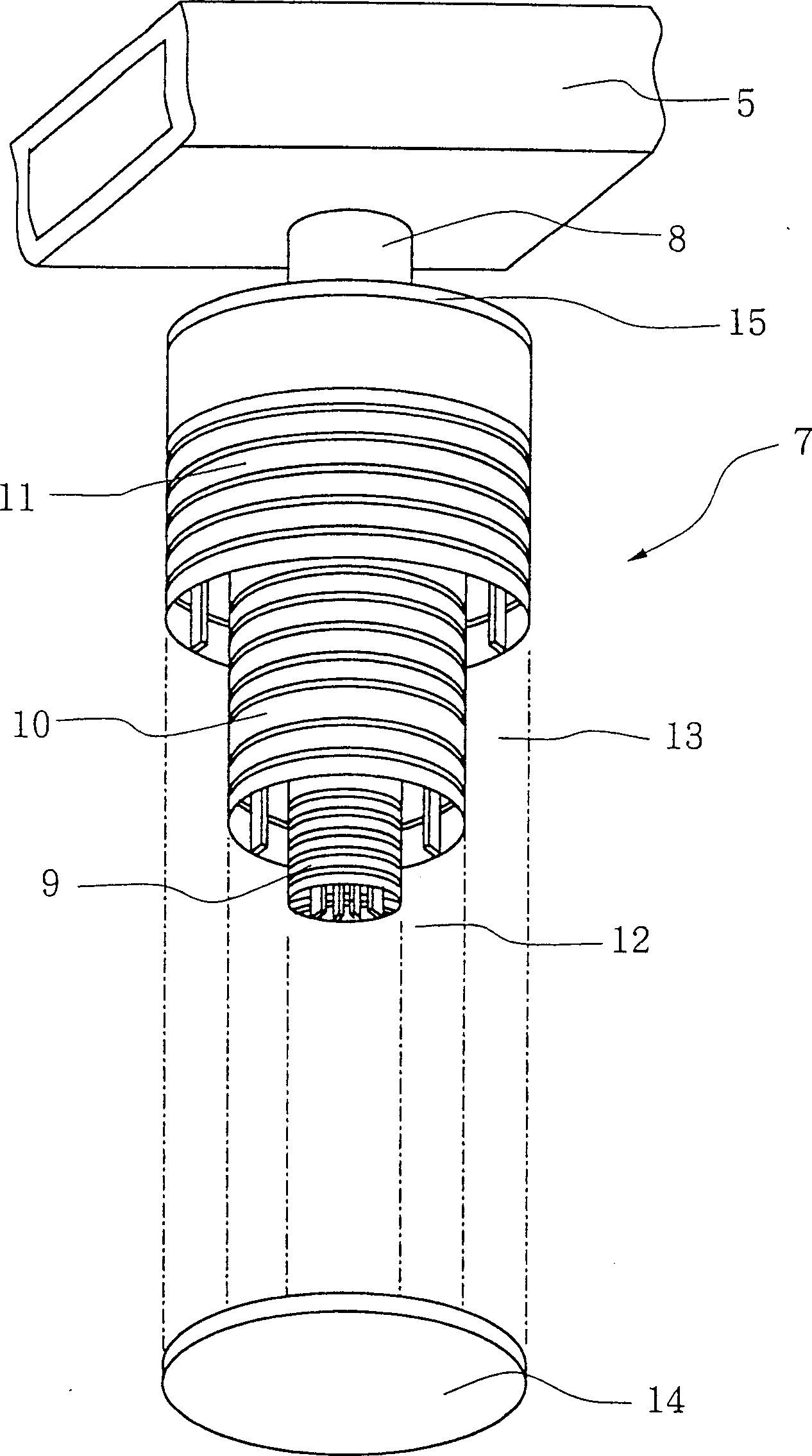

[0052] figure 2 An example of a pre-packed ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com