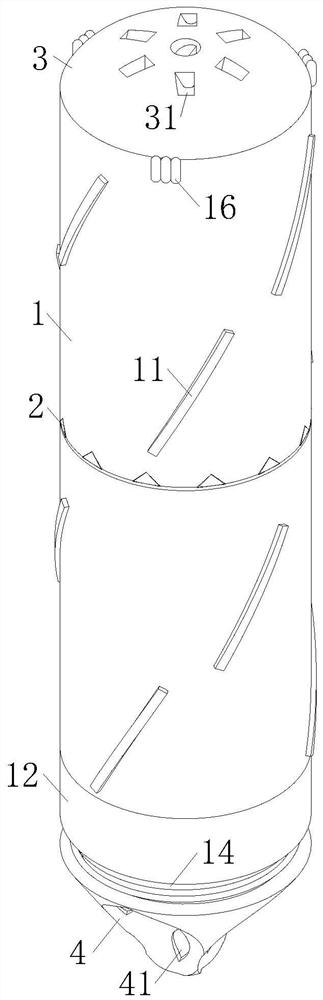

Combined foundation pile composed of steel pipe pile and cement soil pile

A technology of cement-soil piles and steel pipe piles, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of coating drainage, weakening soil arch effect, and not taking into account, so as to achieve the effect of stabilizing the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

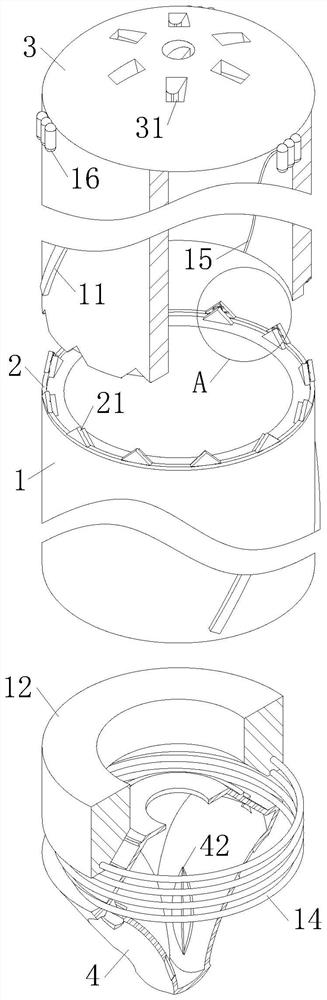

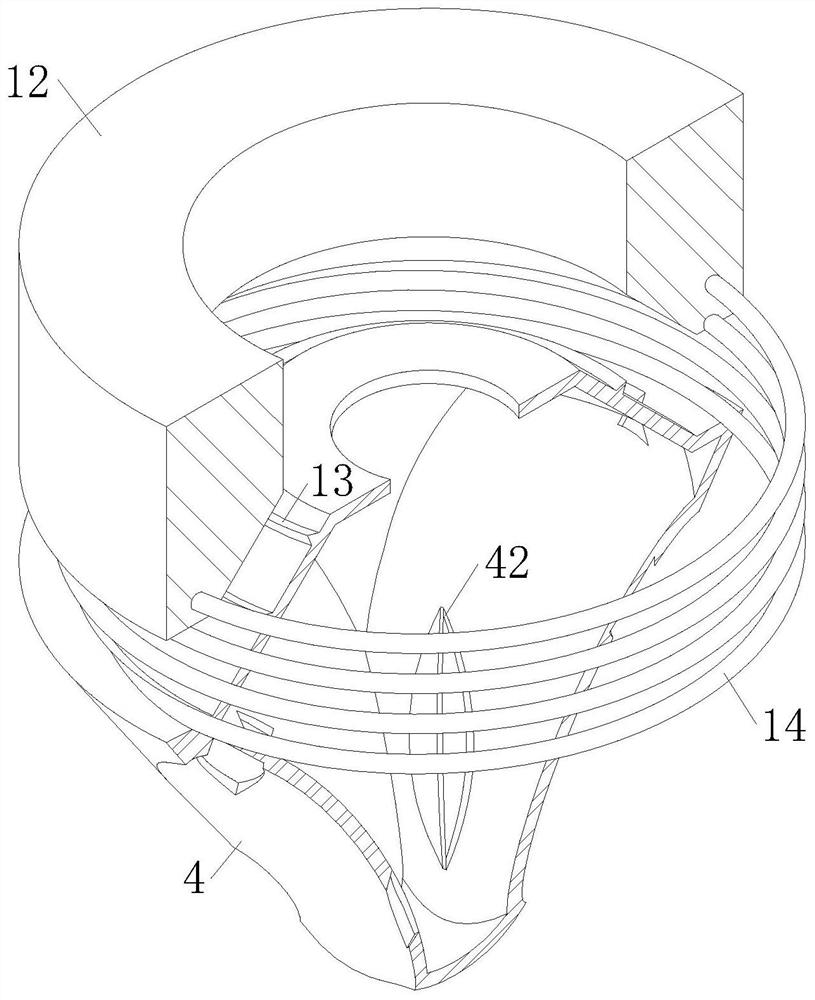

[0029] As an embodiment of the present invention, the bottom of the pile body 1 is also provided with a raised pile barrel 12, and the pile body 1 is in rotational contact with the pile corner 4 through the pile barrel 12; the pile barrel 12 wraps the pile corner 4 Get up, be provided with the spiral groove 13 that meshes between pile barrel 12 and the contact surface of pile angle 4, the circumferential outside of pile barrel 12 is provided with damping spring 14, and the two ends of damping spring 14 are respectively rotatably connected to pile body 1 and on the pile corner 4; when the steel pipe pile touches the changing soil profile during feeding, the pile corner 4 at the bottom of the pile body 1 is susceptible to a large deflection moment. On the pile barrel 12, cooperate with the shock absorbing spring 14 rotating therebetween, when the pile corner 4 contacts the variable section with increased hardness of the soil layer, the feed rate of the pile corner 4 is reduced by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com