Concrete pouring device and method for shield launching base

A concrete and foundation technology, which is applied in the direction of earth drilling, mining equipment, tunnels, etc., can solve the problems affecting the pouring quality of the starting foundation of shield tunneling, the difficulty of keeping the concrete in a fixed position, and the restriction of the layout of detection points, etc., to ensure the pouring Quality, installation is simple and convenient, and the effect of controlling construction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

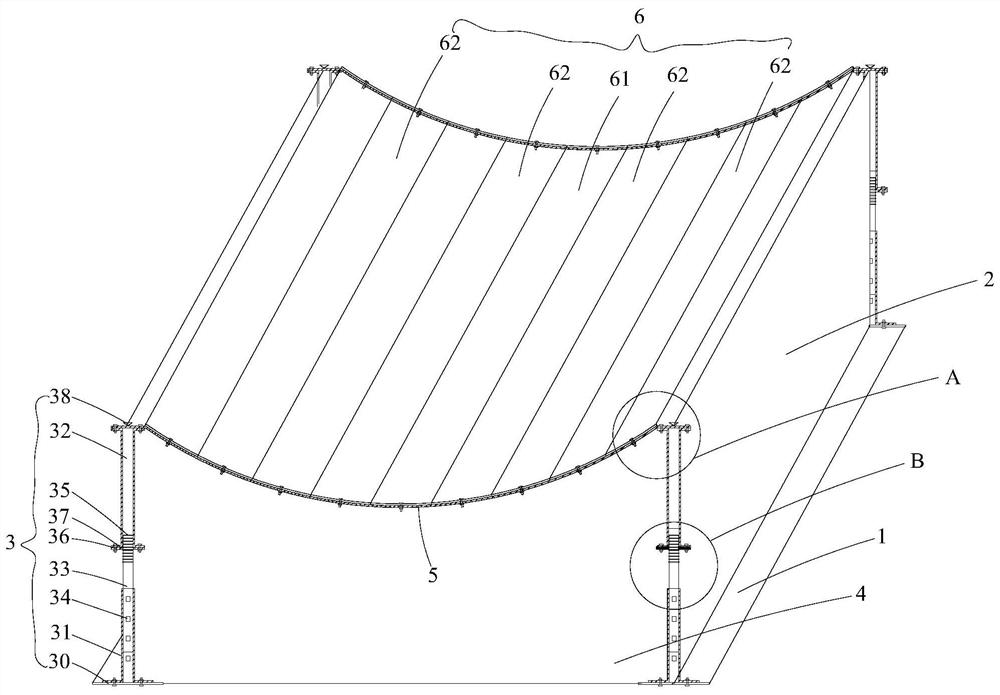

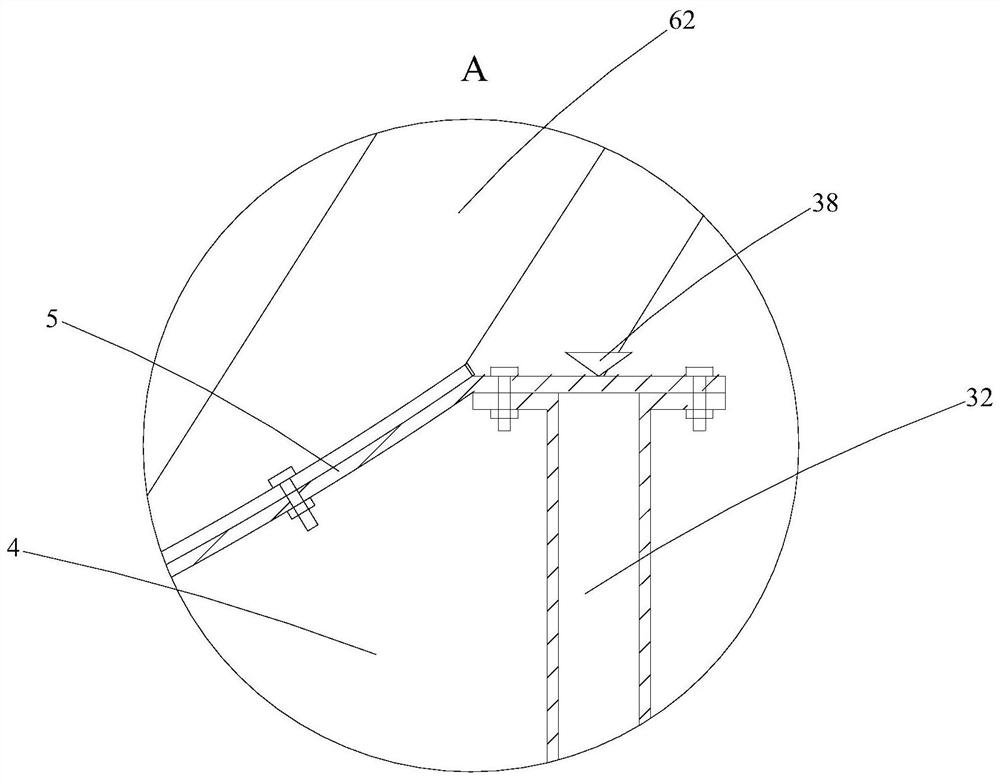

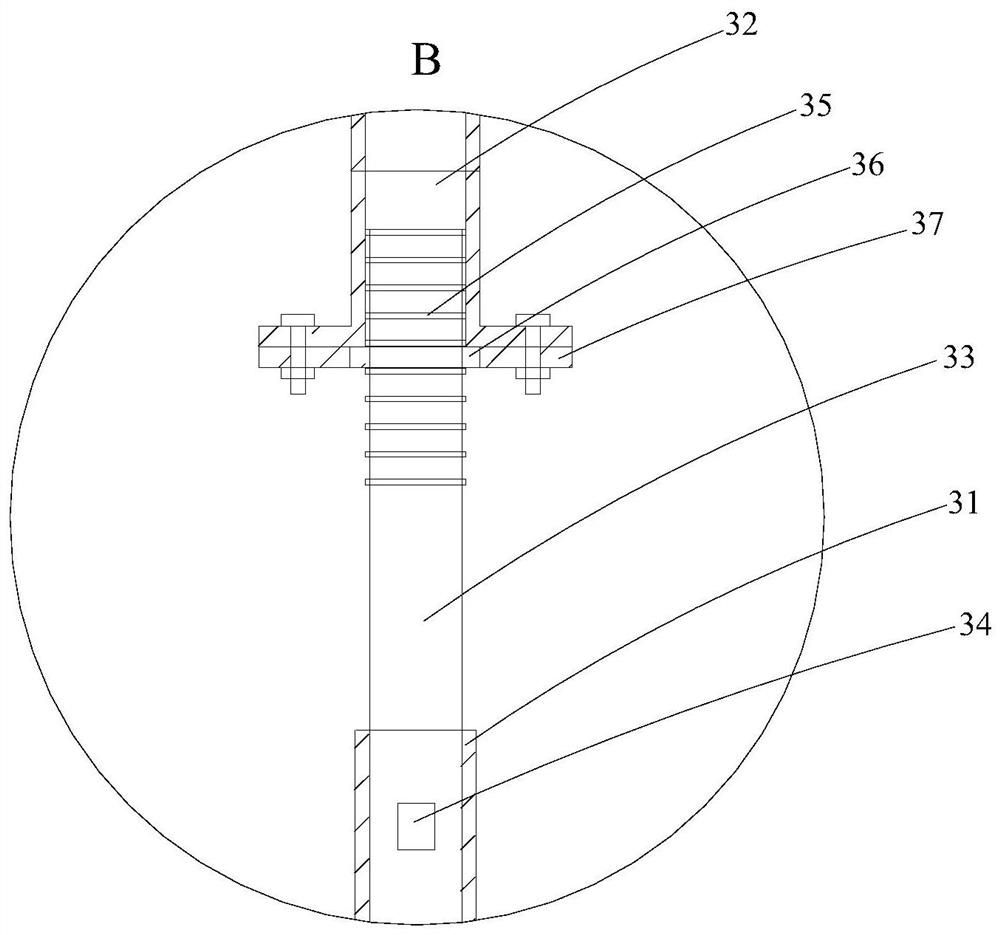

[0037] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0038] The invention relates to the improvement of the concrete pouring of the starting base of the shield machine, so as to solve many problems existing in the arc surface pouring of the current starting base of the shield machine. The present invention innovatively proposes a concrete pouring device for the starting base of the shield machine. The formwork body, arc-shaped top beam and multiple top plates arranged on the basis of the side plates can form a circular-arc surface at the top for pouring. When pouring, it is only necessary to install the formwork body and the arc-shaped top beam, and then pour concrete while installing the top plate, which can effectively ensure the quality of concrete pouring on the arc surface.

[0039] see Figure 1-3 As shown, a concrete pouring device for the starting base of the shield machine is shown, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com