Linear continuous filling peristaltic pump

A peristaltic pump, linear technology, applied in the field of linear continuous filling peristaltic pump, can solve the problems of waste, reduce filling efficiency, energy waste, etc., to save filling time, increase filling volume, reduce installation volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

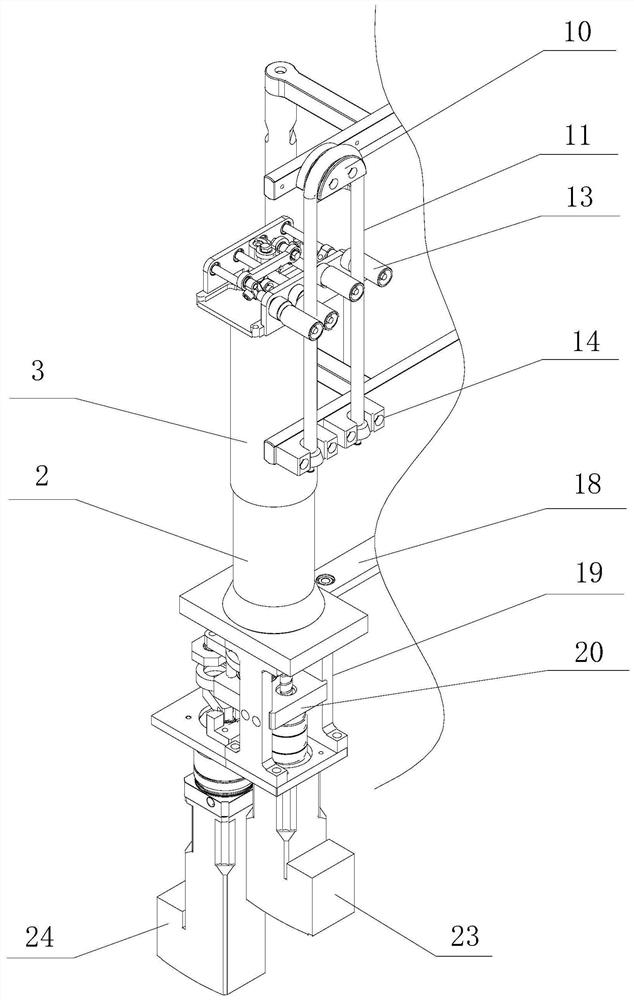

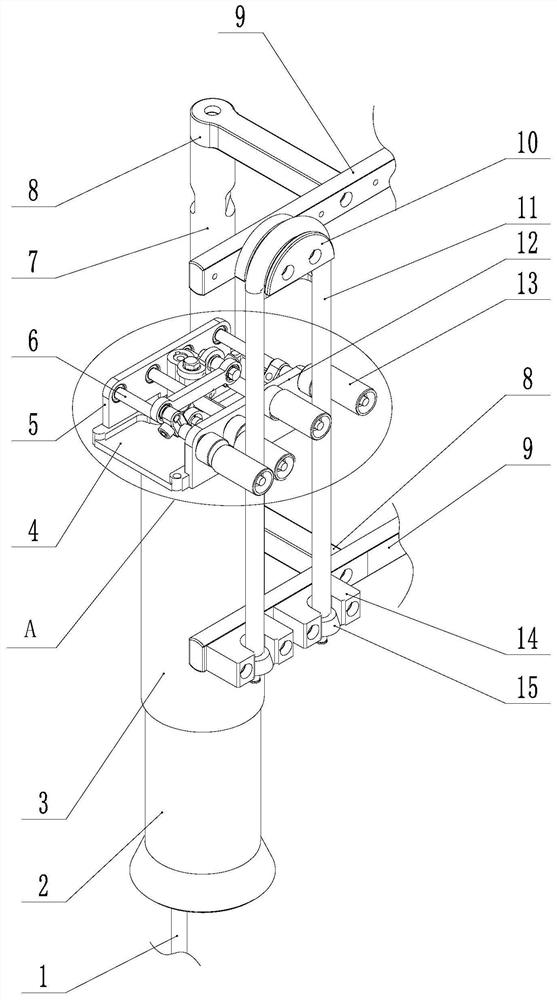

[0031] like Figure 1 to Figure 4As shown, a linear continuous filling peristaltic pump of the present invention includes: a pump body assembly, a pipeline assembly, a pressure tube assembly and a linear reciprocating assembly. The pipeline assembly includes a hose 11 and a hose bracket assembly. The hose bracket assembly is arranged on the side of the pump body. The middle part of the hose 11 is suspended on the top of the hose bracket assembly. The bottom end of the pipe bracket assembly is arranged in a straight line between the middle part and both ends of the flexible pipe 11 . Both the linear reciprocating assembly and the pressing tube assembly are installed on the pump body assembly, and the linear reciprocating assembly is used to drive the pressing tube assembly to perform linear reciprocating motion. In one cycle of the linear reciprocating movement of the compression tube assembly, the compression tube assembly first performs hose extrusion along the input end of ...

Embodiment 2

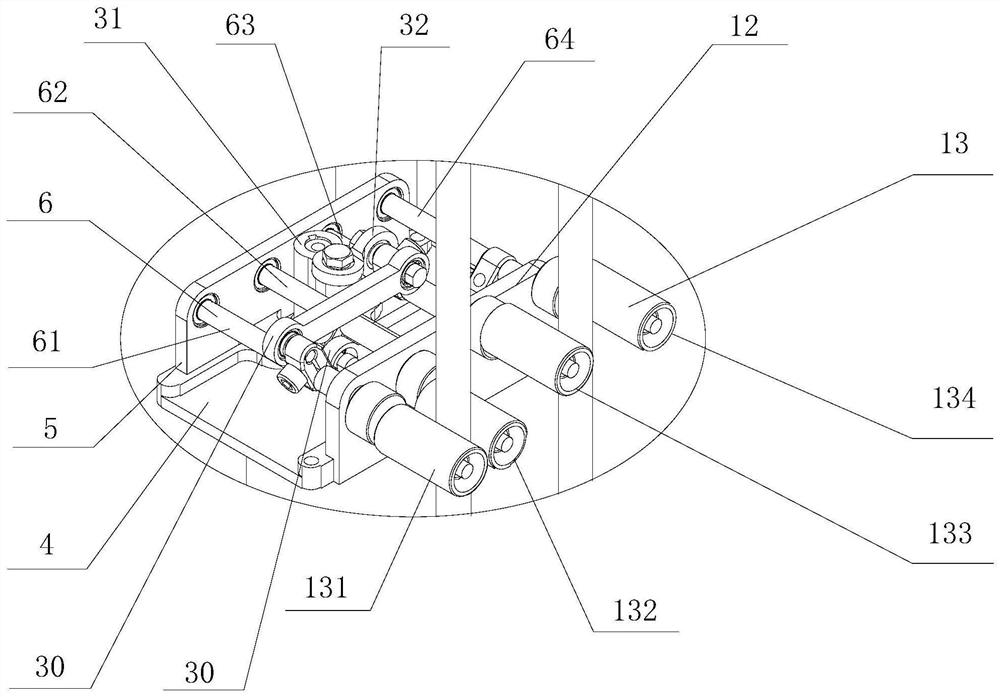

[0047] like Figure 5 As shown, the linear continuous filling peristaltic pump of the present invention has roughly the same structure and working principle as the linear continuous filling peristaltic pump in Embodiment 1, the difference is that the roller mounting shaft 6 includes the first roller mounting shaft 61 and the second roller installation shaft 62, the two ends of the first roller installation shaft 61 and the second roller installation shaft 62 are provided with rollers, that is, the two ends of the first roller installation shaft 61 are respectively provided with the second roller 132 and the second roller 132. Four rollers 134 , the first roller 131 and the third roller 133 are respectively provided at the two ends of the second roller installation shaft 62 . The first roller mounting shaft 61 and the second roller mounting shaft 62 are both eccentric shafts, and are connected to the spline shaft 1 through corresponding swing rod sleeves 31 , cross connecting r...

Embodiment 3

[0051] like Image 6 As shown, a linear continuous filling peristaltic pump of the present invention has substantially the same structure and working principle as the linear continuous filling peristaltic pump in Embodiment 1, the difference is that the roller mounting shaft 6 includes a first roller Installation shaft 61, the second roller installation shaft 62 and the third roller installation shaft 63, one end of three roller installation shafts is fixed on the rear seat 5, and the other end passes through the front seat 12 and is provided with rollers. That is, a first roller 131 is provided at the end of the first roller installation shaft 61 , a second roller 132 is provided at the end of the second roller installation shaft 62 , and a third roller 133 is provided at the end of the third roller installation shaft 63 . The hose 11 runs between the first roller 131 , the second roller 132 and the third roller 133 .

[0052] In this embodiment, the first roller mounting sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com