Novel efficient methanol synthesis tower

A methanol synthesis tower and high-efficiency technology are applied in the field of new high-efficiency methanol synthesis towers, which can solve the problems of reduced conversion efficiency, low conversion efficiency, and low concentration of methanol synthesis reaction, and achieve accelerated heat dissipation, increased conversion efficiency and conversion rate, and increased The effect of conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

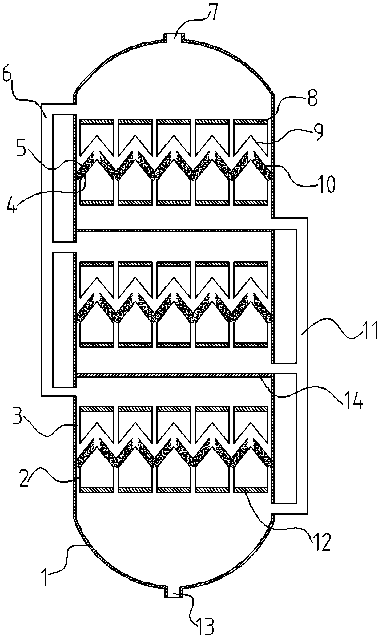

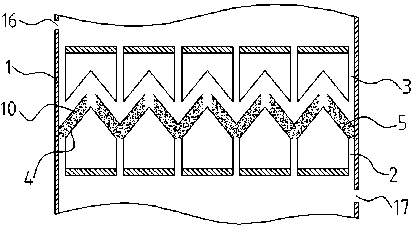

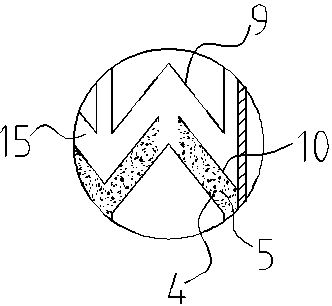

[0036] A new high-efficiency methanol synthesis tower, comprising a tower body 1, the top of the tower body 1 is provided with a gas supply nozzle 7, and the bottom is provided with a methanol outlet 13, and the tower body 1 is divided into several reaction chambers by partitions 14; The reaction chamber is communicated with the gas distribution pipe 6 and the liquid collecting pipe 11; the reaction chamber is provided with a combined tray; the combined tray includes a first tray 10 and a second tray 4; the first tray Tray 10 is positioned at the top of second tray 4; Described first tray 10 and second tray 4 are all provided with several conical cavities; The bottom opening of described conical cavity, and place tray The lower space of the first tray 10 is connected with the conical cavity on the first tray 10 and the conical cavity on the second tray 4 has the same shape size, quantity and open position; the first tray 10 and the second tray 4 The two trays 4 cooperate with ...

Embodiment 2

[0039] The difference between embodiment 2 and embodiment 1 is that the upper tube plate 8 is located above the first tray 10, and several inlet pipes 3 are vertically arranged between the upper tube plate 8 and the first tray 10; The upper end of the air inlet pipe 3 runs through the upper tube sheet 8 , and the lower end communicates with the second air inlet 19 on the first tray 10 . The arrangement of the upper tube sheet 8 can protect the first tray 10 to a certain extent, preventing the high-pressure low-temperature mixed gas from being directly sprayed onto the first tray 10 below the gas supply nozzle, causing damage to the first tray 10 . The upper tube sheet 8 is fixedly connected to the inner wall of the tower body. The low-temperature synthesis gas enters the tower from the gas supply nozzle 7 at the top of the methanol synthesis tower, passes through the upper tube plate 8, and is directly transported to the reaction layer by the inlet pipe 3 for reaction. The up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com