A proppant for hydraulic fracturing of coalbed methane and shale gas and its preparation method

A hydraulic fracturing and proppant technology, which is used in earth-moving drilling, production of fluids, wellbore/well components, etc., can solve the problems that the upper part cannot be effectively filled, the density of proppant is high, etc., and improve the sand-carrying capacity. , the effect of increasing the filling volume and improving the flow conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

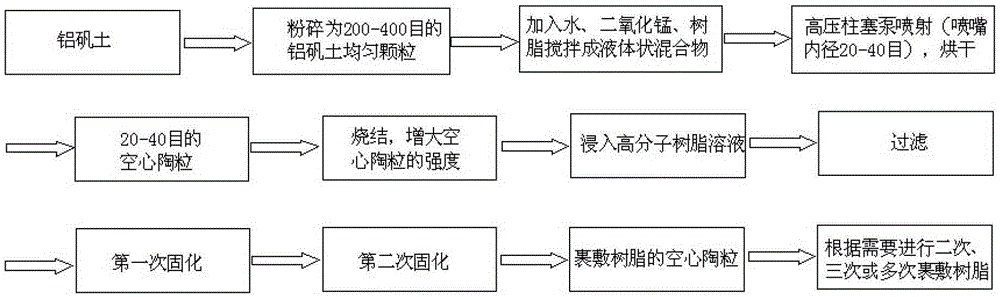

[0045] The preparation steps of proppant used in coalbed methane and shale gas hydraulic fracturing are as follows:

[0046] 1) Crush the bauxite into 200-300 mesh uniform particles, add water and manganese dioxide powder to the above uniform particles according to the weight ratio of bauxite, water, manganese dioxide and resin at 39:60:0.5:0.5 , resin, stirred to a liquid mixture; using a high-pressure plunger pump with a plunger pump nozzle inner diameter of 20-40 mesh to spray the liquid mixture onto a drying tower with a height of 20 meters, and dry it at 800 ° C , forming 20-40 mesh hollow ceramsite;

[0047] 2) Put the hollow ceramsite prepared in step 1) into a rotary kiln, sinter at 1300°C for 4 hours, and then cool to obtain 20-40 mesh high-strength hollow ceramsite;

[0048] 3) Put the 20-40 mesh high-strength hollow ceramsite prepared in step 2) into 10% ethanol solution of phenolic resin and soak for 24 hours. The hollow ceramsite soaked in the ethanol solution i...

Embodiment 2

[0053] 1) Crush bauxite into 300-400 mesh uniform particles, add water and manganese dioxide powder to the above uniform particles according to the weight ratio of bauxite, water, manganese dioxide and resin at 39:60:0.5:0.5 , resin, stirred to a liquid mixture; using a high-pressure plunger pump with a plunger pump nozzle inner diameter of 20-30 mesh, spray the liquid mixture onto a drying tower with a height of 20 meters, and dry it at 1000 ° C , forming 20-30 mesh hollow ceramsite;

[0054] 2) Put the hollow ceramsite prepared in step 1) into a rotary kiln, sinter at 1500°C for 5 hours, and then cool to obtain 20-30 mesh high-strength hollow ceramsite;

[0055] 3) Put the 20-30 mesh high-strength hollow ceramsite prepared in step 2) into 15% ethanol solution of phenolic resin and soak for 18 hours. The hollow ceramsite soaked in the ethanol solution is put into the curing equipment with a stirring mechanism for the first curing, the curing temperature is 100°C, and the cur...

Embodiment 3

[0060] 1) Crush bauxite into 300-400 mesh uniform particles, add water, manganese dioxide powder, and resin to the above uniform particles, and stir until a liquid mixture; use a plunger pump nozzle with a high-pressure plunger with an inner diameter of 30-40 mesh The pump sprays the liquid mixture onto a drying tower with a height of 20 meters, and dries at 900°C to form 30-40 mesh hollow ceramsite;

[0061] 2) Put the hollow ceramsite prepared in step 1) into a rotary kiln, sinter at 1200°C for 5 hours, and then cool to obtain 30-40 mesh high-strength hollow ceramsite;

[0062] 3) Put the 30-40 mesh high-strength hollow ceramsite prepared in step 2) into 20% ethanol solution of phenolic resin and soak for 15 hours. The hollow ceramsite soaked in the ethanol solution is put into the curing equipment with a stirring mechanism for the first curing, the curing temperature is 60°C, and the curing time is 3 hours;

[0063] 4) After the first curing, raise the temperature of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com