Solder resist resin composition, solder resist structure, dry film and printed wiring board

A technology of resin composition and structure, applied in printed circuit, printed circuit manufacturing, printed circuit parts, etc., can solve the problems of high cost and complicated OLED display manufacturing process, and achieve the effect of excellent dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0082] The solder resist resin composition of the present invention may contain an organic solvent for the purpose of preparation of the composition, viscosity adjustment at the time of coating on a substrate or a carrier film, and the like. As the organic solvent, known and commonly used organic solvents can be used, such as esters; aliphatic hydrocarbons such as octane and decane; petroleum solvents such as petroleum ether, petroleum naphtha, and solvent naphtha. These organic solvents can be used individually or in combination of 2 or more types.

[0083] The solder resist resin composition of the present invention may contain an antioxidant. Usually, since an antioxidant is included to prevent oxidative deterioration of curable resins, etc., it has the effect of suppressing discoloration and the effect of improving heat resistance and resolution (line width reproducibility). That is, depending on the type of white colorant, the resolution may be deteriorated by reflecting...

Embodiment

[0104] Hereinafter, the present invention will be described in detail using examples.

[0105] Preparation of Fluorescent Particles Containing Phosphors and Colorants

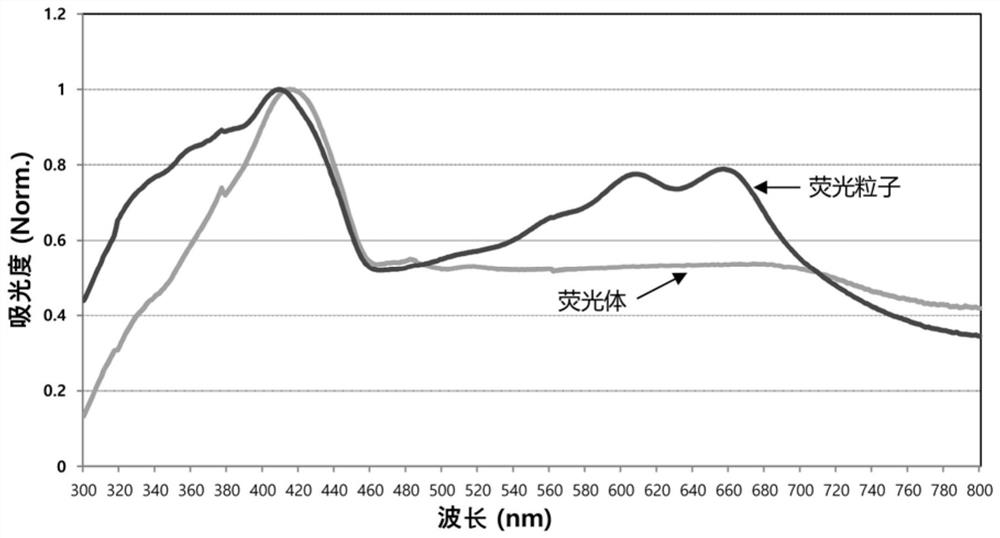

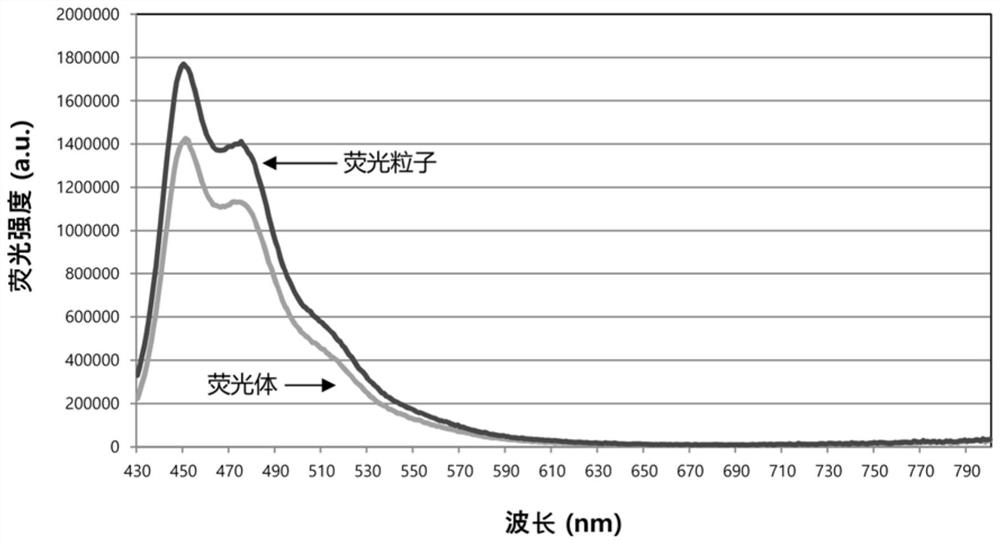

[0106] Prepared phosphor 1,4-bis(2-benzoxazolyl)naphthalene with 90-92 mass percent, 4,4'-bis[2-(2-methoxyphenyl) with 7-8 mass percent ) PhosphorBlue440, a particle-form phosphor mixture of vinyl]-1,1'-biphenyl.

[0107] Phosphor Blue OEF-BTS, the fluorescent particle, was prepared by coating the phosphor mixture PhosphorBlue440 with the colorant 1,4-bis(butylamino)anthracene-9,10-dione. The mass ratio of the above-mentioned phosphor mixture Phosphor Blue440 to the colorant coated with it is 100:0.2.

[0108] Size of Phosphors and Phosphor Particles

[0109]The size or diameter of the phosphor (Phosphor Blue440) and fluorescent particles (Phosphor Blue OEF-BTS) can be measured using a particle size analyzer, a grinder, or the like. The size measurement result of the above phosphor Phosphor Blue440 was 5 μm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Emission peak | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap