Double-layer DP connector and manufacturing process thereof[

A connector and double-layer technology, which is applied in the field of double-layer DP connectors and its manufacturing process, can solve the problems of high production cost, difficult realization, and disconnection, and achieve ingenious and reasonable design of positioning relationship and assembly method. Good controllability of position accuracy, ensuring the effect of combining reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

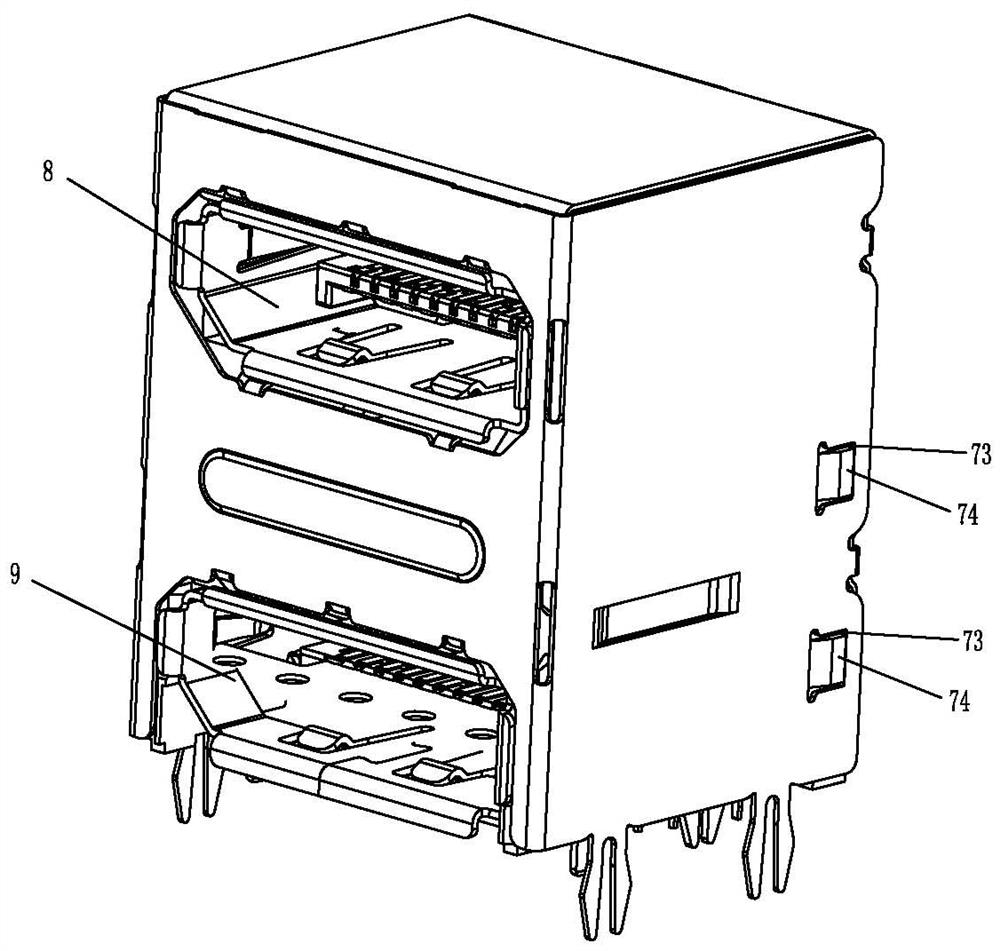

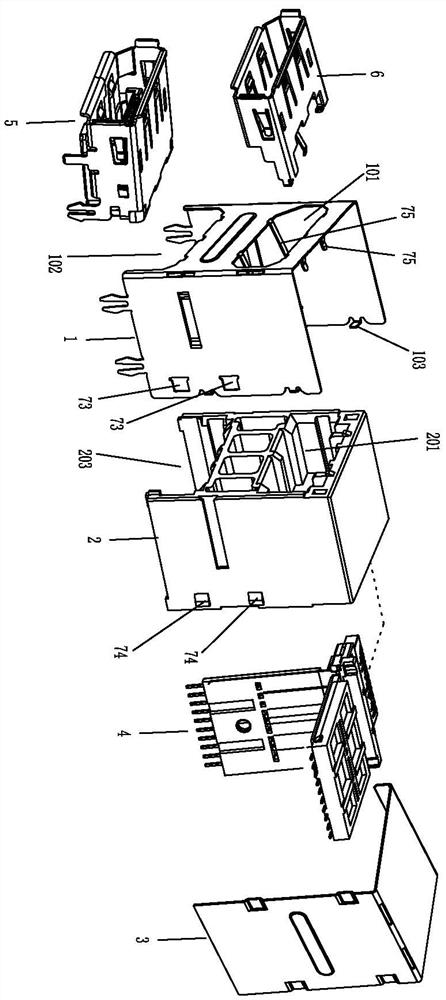

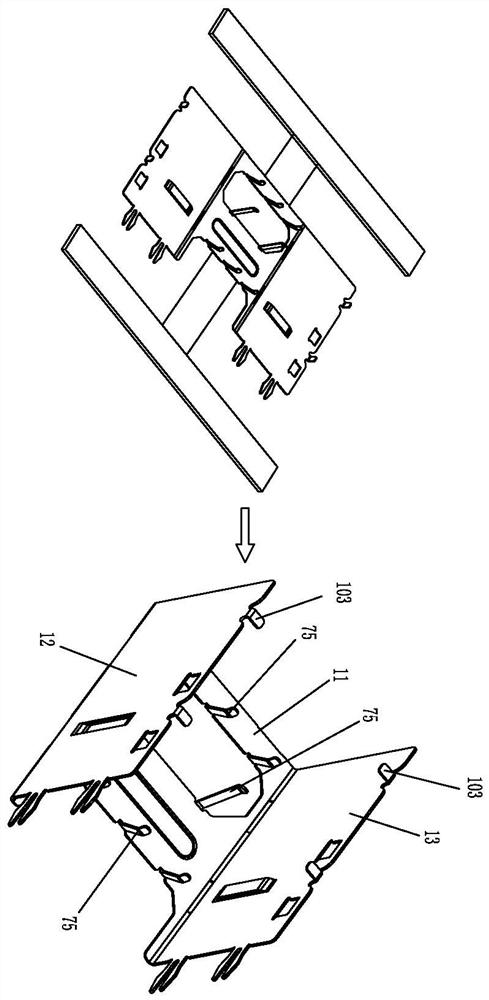

[0056] Please refer to Figure 1 to Figure 16 As shown, it shows the specific structure of the embodiment of the present invention.

[0057] A double-layer DP connector, including a DP shell 1, a DP plastic body 2, a rear cover 3, an upper DP shell 6, an upper DP Molding component 4, and a lower DP connector module 5; wherein, the DP shell 1 covers Outside the DP plastic body 2, the rear cover 3 is covered on the rear side of the DP plastic body 2 and spliced with the DP shell 1, so as to cover the multiple sides of the DP plastic body 2 (mainly referring to the front, rear, left, right and top, bottom for terminal's solder leg sticking out). The upper DP shell 6 is installed in the upper area of the DP plastic body 2 , the upper DP Molding component 4 is installed in the upper DP shell 6 , and the lower DP connector module 5 is installed in the lower area of the DP plastic body 2 . The upper-layer DP Molding assembly 4 and the upper-layer DP shell 6 form an upper-laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com