Pressure-sensitive color developing protective film, preparation method thereof, and battery

A technology of protective film and color development, which is applied in the field of lithium-ion batteries, can solve the problems of inability to monitor the flatness of hot-pressing forming equipment in real time, and facilitate timely adjustment, save testing time, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

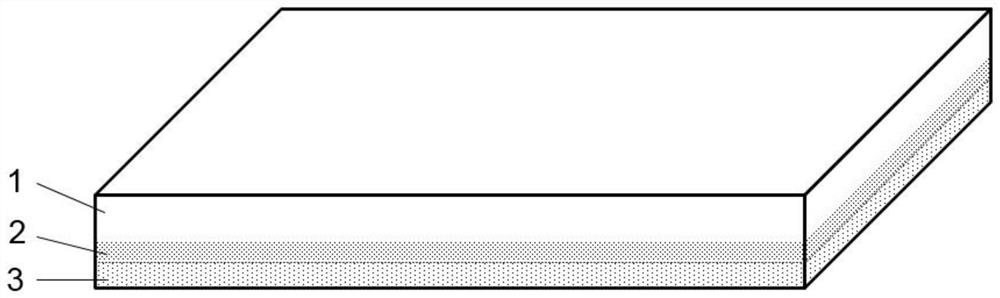

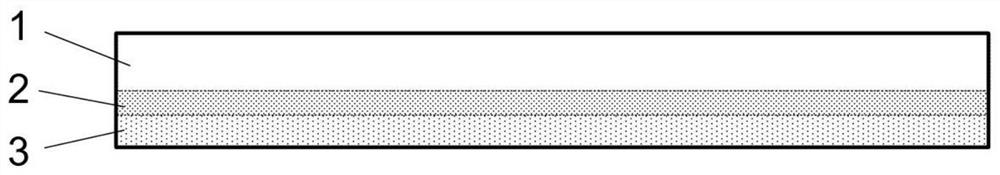

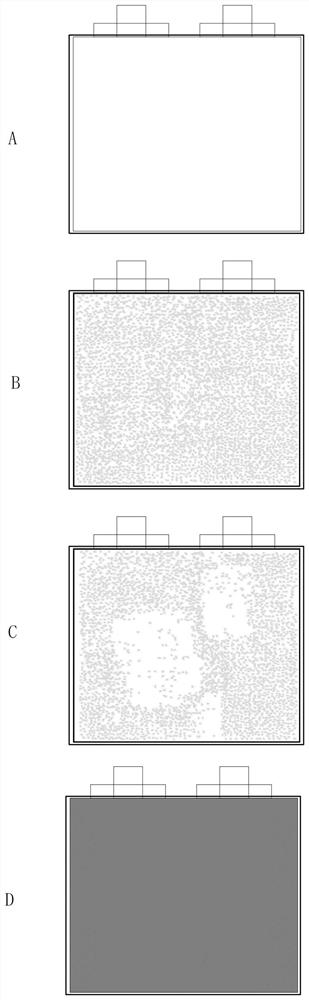

Embodiment Construction

[0035] Lithium battery manufacturing process generally comprises the steps of: mixing, coating, cold, pieces, winding (or laminate), injection, into and capacity. Wherein the formation is a critical step to improve the electrical performance of the lithium battery. It is first formed into a battery across the electrodes into the appropriate low current inside the battery activation process of the active material. Soft package lithium ion battery into a hot press, the battery can be removed prior shaping process into the baking process, while reducing the working period, reduce battery production cycle, a significant reduction in labor, is more conducive to the battery after sealing the battery more smooth evacuation. In the hot pressing process into the lithium ion battery, the battery hot great influence on the flatness of the lithium ions into the device for pressing the pressure into a lithium ion battery, and hot pressing into a great pressure on the battery performance, Jorge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com