Solar power generation panel waste heat recovery cleaning device and control method

A technology for solar power generation panels and waste heat recovery, applied in the energy field, can solve problems affecting the power generation efficiency of solar power generation panels, low efficiency of solar power generation panels, waste of resources, etc., and achieve the effects of strong independence, simple structure, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

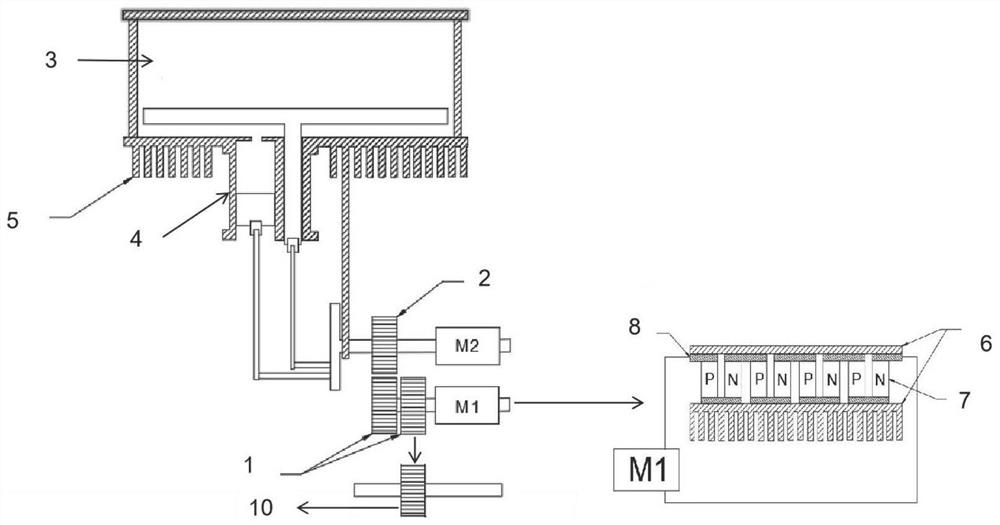

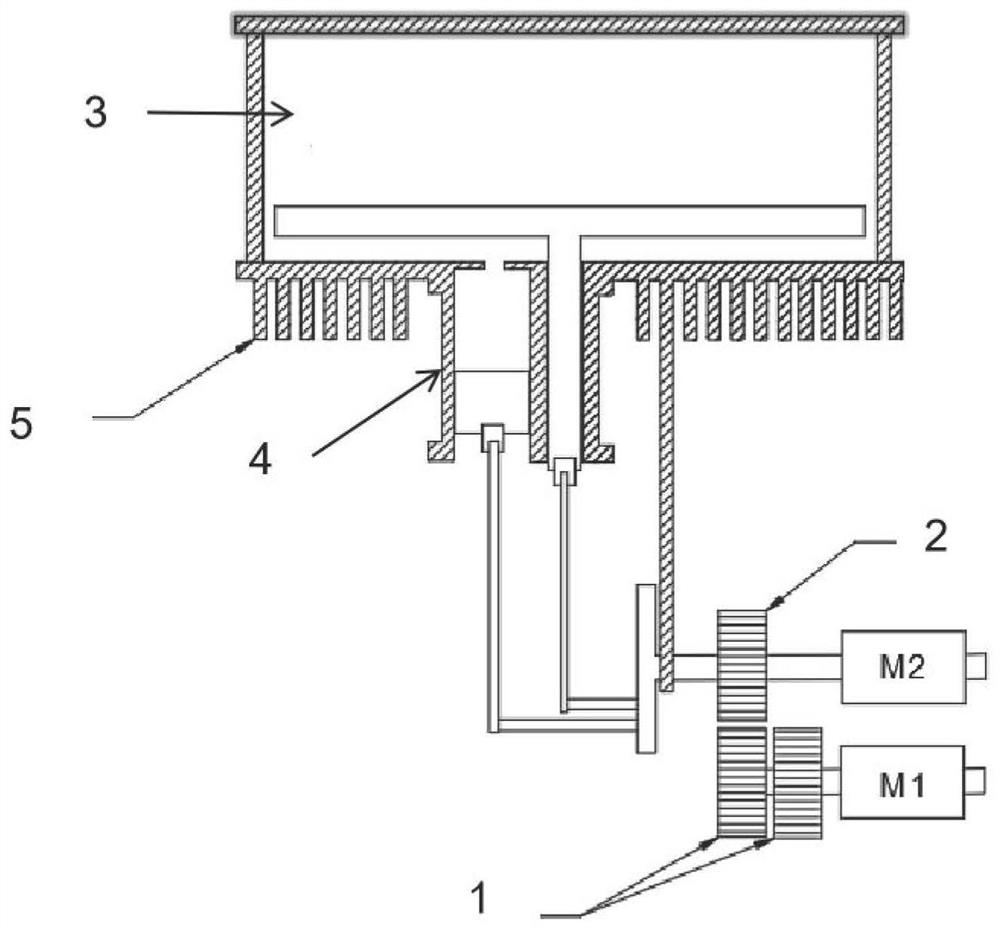

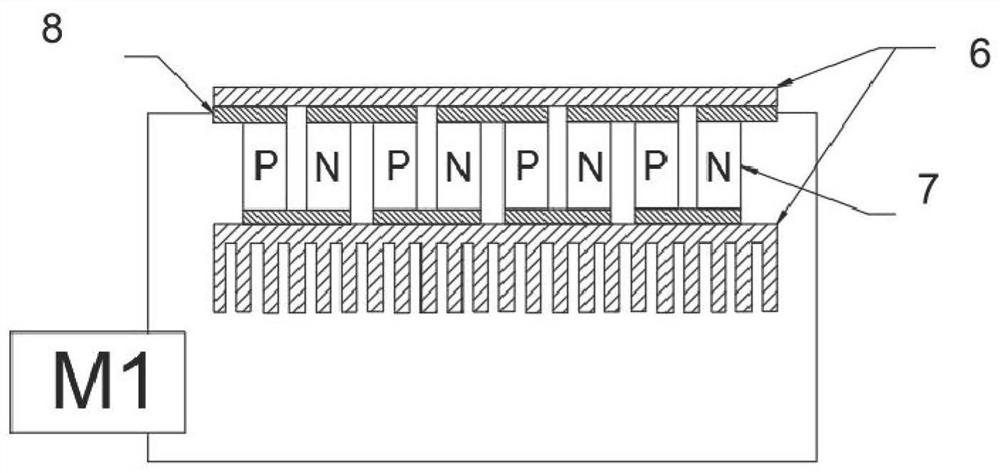

[0025] like Figure 1-7 As shown, the solar power generation panel waste heat recovery cleaning device of the present invention includes a Stirling heat engine, a starter motor M1, a DC generator M2, a solar power generation panel cleaner, and a low-speed transmission device 1; the thermal chamber of the Stirling heat engine 3 are distributed on one side of the heat dissipation plate of the solar power generation panel; the starter motor M1 includes a rotor, which is connected to the low-speed transmission device 1, and is connected to the transmission device 2 of the Stirling heat engine and the solar power generation device through the low-speed transmission device 1 respectively. The transmission wheel 10 of the panel cleaner is connected; the DC generator M2 is driven by a Stirling heat engine; the transmission wheel 10 of the solar panel cleaner is connected with the low-speed transmission device 1, and realizes power transmission; the After the solar power generation pan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com