Apple peeler

A peeling machine and apple technology, which is applied in the fields of vegetable or fruit peeling, fruit de-pitting device, food science, etc., can solve the problems of low standardization, low peeling efficiency, low safety performance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

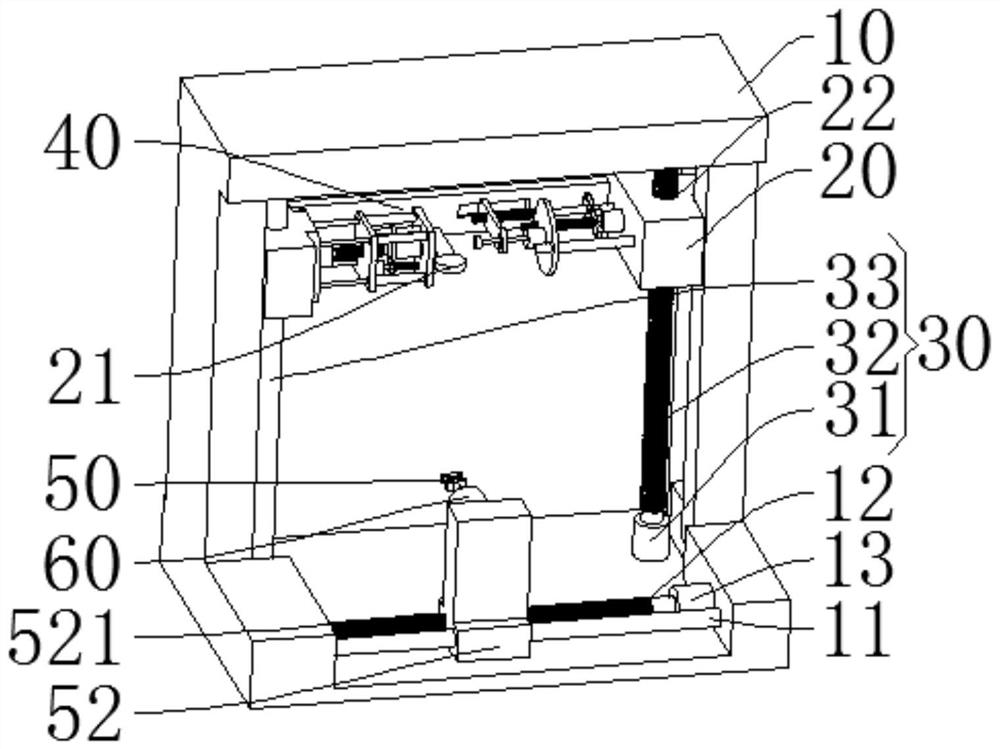

[0031] refer to Figure 1 to Figure 6 , the invention provides an apple peeler, comprising:

[0032] Frame 10, frame 10 is provided with elevating frame 20 and elevating mechanism 30, elevating frame 20 is movable and installed on the frame 10, elevating frame 20 is provided with the storage platform 21 that is used to put apple, elevating mechanism 30 is used for driving Lifting frame 20 moves;

[0033] Clamping assembly 40, the clamping assembly 40 is arranged on the elevating frame 20 and is used for clamping apples, and the clamping assembly 40 can drive the apples to rotate;

[0034] Knife rest 50, the knife rest 50 is arranged on the frame 10, and the knife rest 50 is provided with a knife rest 51 for peeling;

[0035] The feed mechanism 60, the feed mechanism 60 is arranged on the frame 10, the feed mechanism 60 is used to drive the knife rest 50 to move so that the knife rest 51 approaches or moves away from the apple;

[0036] An adjustment mechanism 70, the adjust...

Embodiment 2

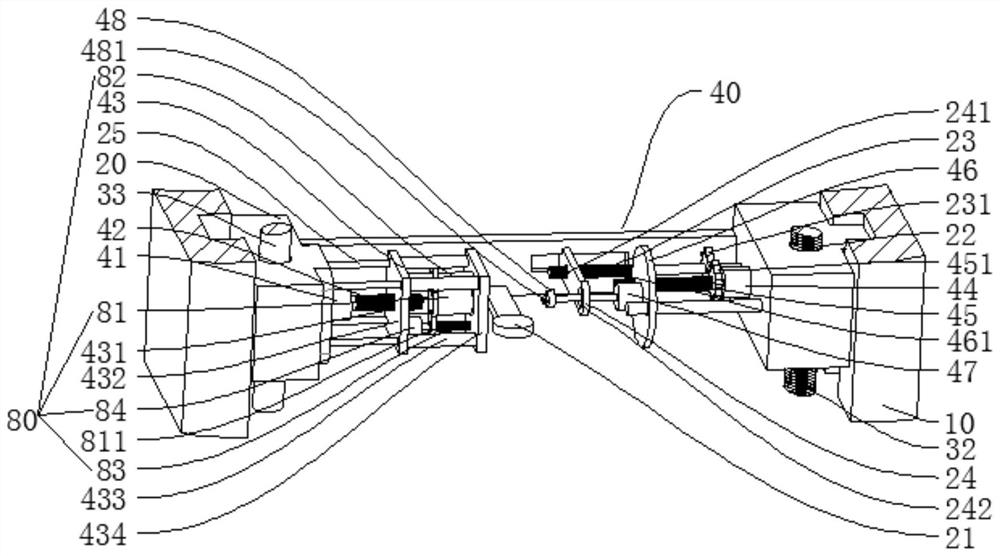

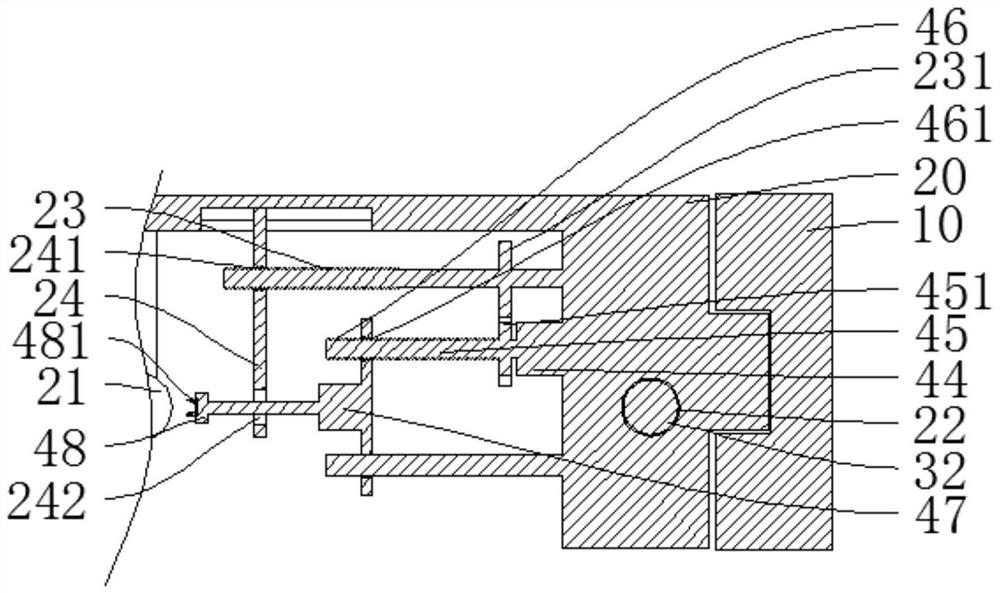

[0042] refer to Figure 1 to Figure 6 , in combination with the technical solution of Embodiment 1, in this embodiment, the clamping assembly 40 includes a first drive motor 41, a first threaded rod 42, a moving frame 43 for resisting apples, a second drive motor 44, a second screw thread Rod 45, moving plate 46, driving motor 47 and the rotating disk 48 that has claw 481, the first driving motor 41 and the second driving motor 44 are all arranged on the elevating frame 20, the first threaded rod 42 and the second threaded rod 45 They are all rotatably installed on the lifting frame 20, and the moving frame 43 and the moving plate 46 are all movable and installed on the lifting frame 20. There is a second threaded hole 461 matched with the second threaded rod 45, the first drive motor 41 is connected with the first threaded rod 42 and is used to drive the first threaded rod 42 to rotate, and the second drive motor 44 is connected to the second threaded rod 45 for transmission....

Embodiment 3

[0052] refer to Figure 1 to Figure 6 , in combination with the technical solutions of embodiment 1 and embodiment 2, in the present embodiment, the frame 10 is provided with a cross bar 11, a fourth threaded rod 12 and a fourth drive motor 13, and the knife rest 50 is provided with a base 52, the base 52 is movable and installed on the cross bar 11 , the fourth threaded rod 12 is arranged on the output shaft of the fourth drive motor 13 , and the base 52 is provided with a fourth threaded hole 521 matching with the fourth threaded rod 12 .

[0053] The fourth drive motor 13 drives the fourth threaded rod 12 to rotate to cooperate with the fourth threaded hole 521 to drive the base 52 to move, so that the base 52 drives the knife rest 50 to move laterally, and the knife rest 51 on the knife rest 50 cooperates with the clamping assembly 40. Apples are peeled.

[0054] Specifically, the feeding mechanism 60 is a driving cylinder, the driving cylinder is arranged on the base 52,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap