A pass for producing i-shaped steel and a rolling method for i-shaped steel

A type of steel and pass technology, applied in metal rolling, metal rolling, metal rolling stands, etc., can solve the problem of high cost of recycling scrap rails, and achieve the advantages of saving resources, excellent mechanical properties, and reducing production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

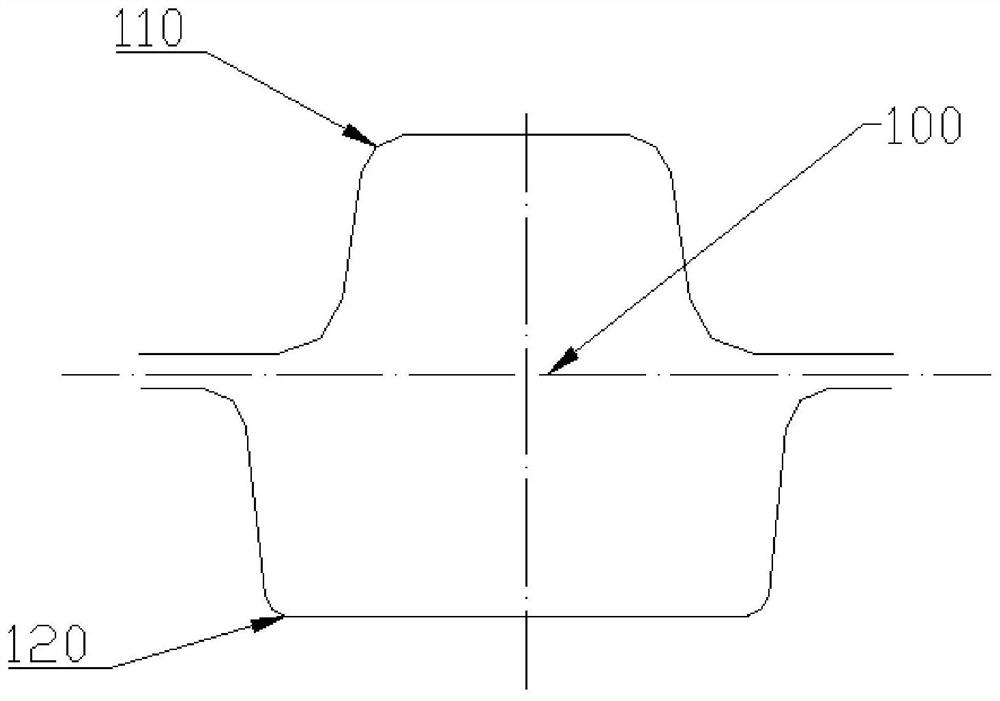

[0058] Please refer specifically to FIG. 1, the first upper rolling groove 110 and the first lower rolling groove 120 are opposite to each other, forming a

[0059] It should be noted that the openings of the first upper rolling groove 110 and the first lower rolling groove 120 are radially away from the opening

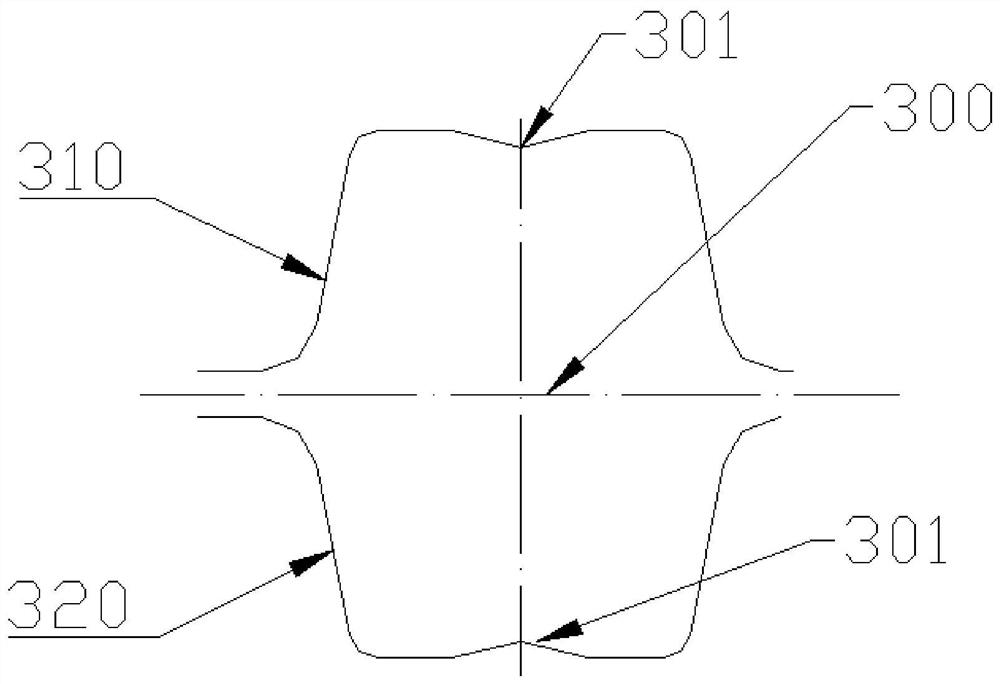

[0060] The third pass pass 300, the third pass pass 300 includes a third upper rolling groove 310 and a third lower rolling groove 320,

[0062] It should be noted that the openings of the third upper rolling groove 310 and the third lower rolling groove 320 are radially away from the opening

[0063] The fourth pass pass 400, the fourth pass pass 400 includes a fourth upper rolling groove 410 and a fourth lower rolling groove 420,

[0065] It should be noted that the openings of the fourth upper rolling groove 410 and the fourth lower rolling groove 420 are radially away from the opening.

[0067] Specifically, please refer to FIG. 5 , the fifth pass of the pass 500 is u...

Embodiment 2

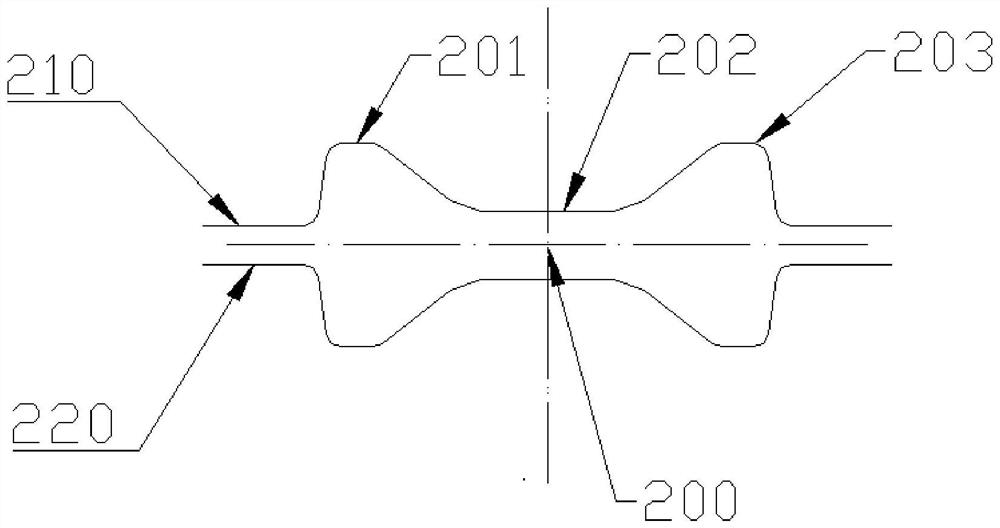

[0073] Please refer specifically to FIG. 2 , the openings of the second upper rolling groove 210 and the second lower rolling groove 220 are opposite, forming an opening

[0074] It should be noted that the openings of the second upper rolling groove 210 and the second lower rolling groove 220 are radially away from the opening

[0075] It should also be noted that the second pass pass is substantially the same as the fourth pass pass.

Embodiment 3

[0079] Specifically, please refer to FIG. 8 , the eighth pass pass 800 is used to incline the rough-rolled scrap rails

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com