Turbine rotor locking plate assembling device and using method thereof

A technology for assembling devices and turbine rotors, which is applied in the direction of feeding devices, positioning devices, storage devices, etc., can solve the problems of blade bumping and blade 10 falling at the same time, so as to ensure the installation quality, improve the installation efficiency, and satisfy the flatness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

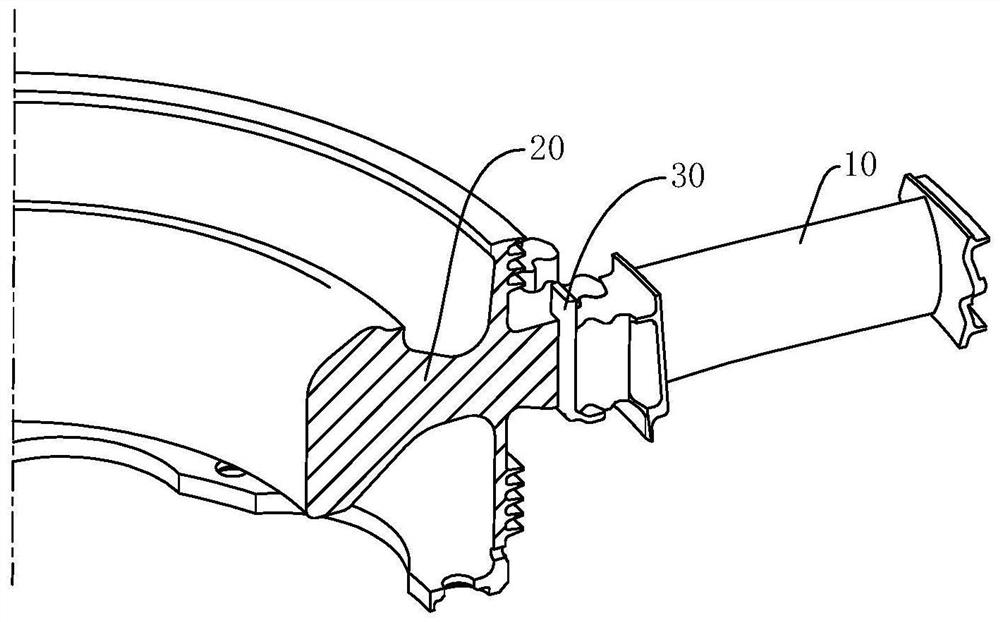

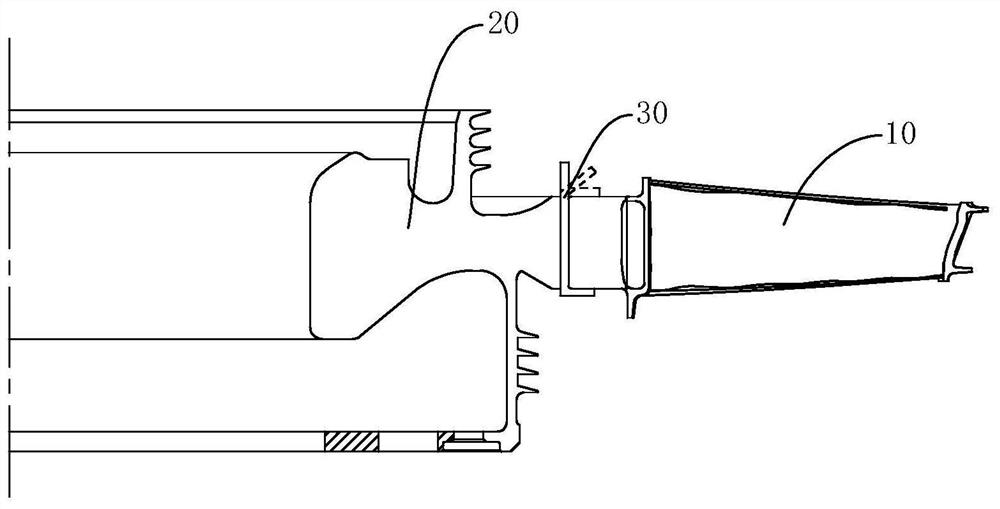

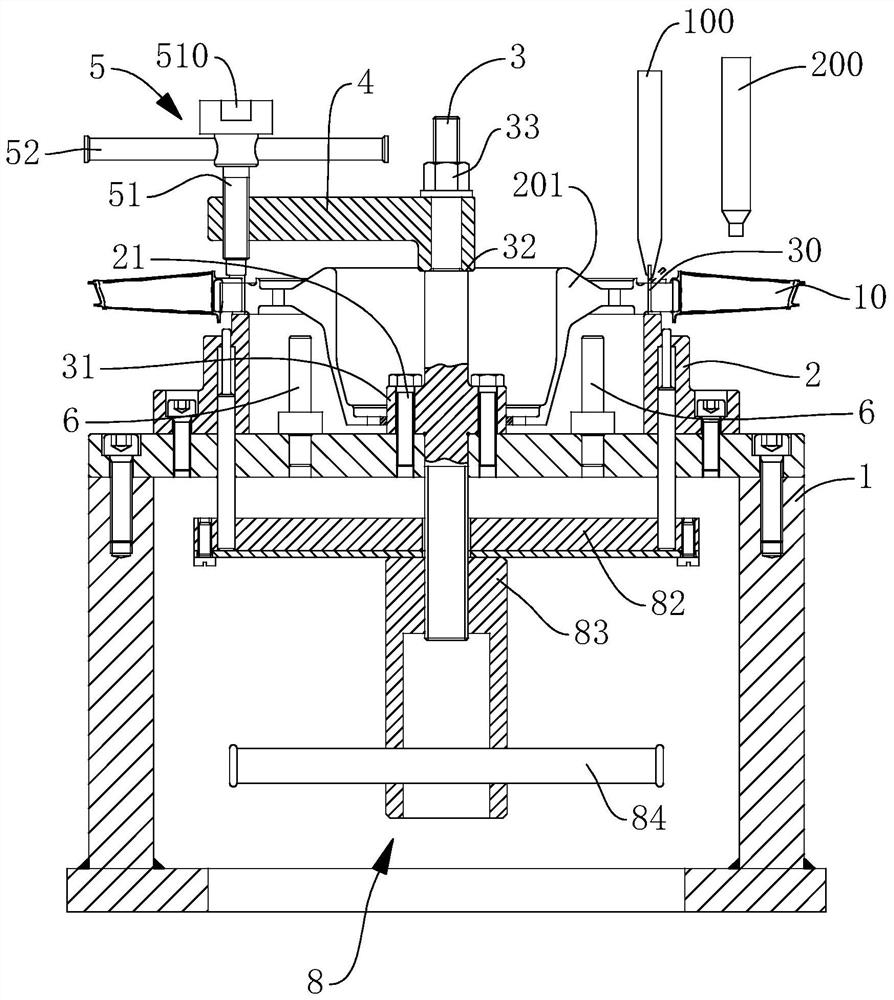

[0027] like image 3 As shown, the embodiment of the present invention provides a turbine rotor locking piece assembly device, which is used for assembling the blade 10 and the locking piece 30 on the turbine disk 20 . The turbine disk 20 is divided into a first-stage turbine disk 201 and a second-stage turbine disk 202 . The turbine rotor locking plate assembly device includes a base 1 , a support 2 , a pull rod 3 , a rotating arm 4 and a pressing assembly 5 . The support 2 is fixed on the base 1 , and the top surface of the support 2 is used to support the lower bent portion of each locking piece 30 on the first-stage turbine disk 201 . The pull rod 3 is vertically fixed on the horizontal support portion of the base 1 and arranged coaxially with the support 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com