Workpiece unloading device of semi-automatic lathe for machining tricycle accessories

A workpiece unloading, semi-automatic technology, used in metal processing machinery parts, metal processing, metal processing equipment and other directions, can solve the problems of workpiece surface heating, workpiece surface damage, easy to hit the workpiece, etc., to improve quality, improve work efficiency, height reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

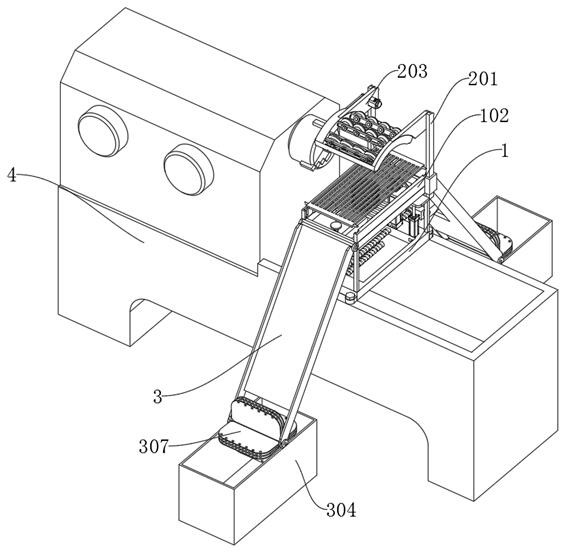

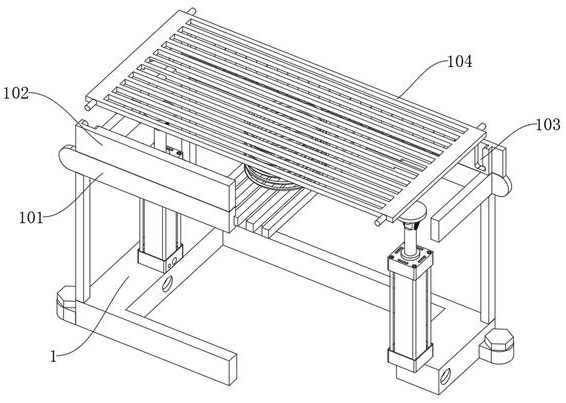

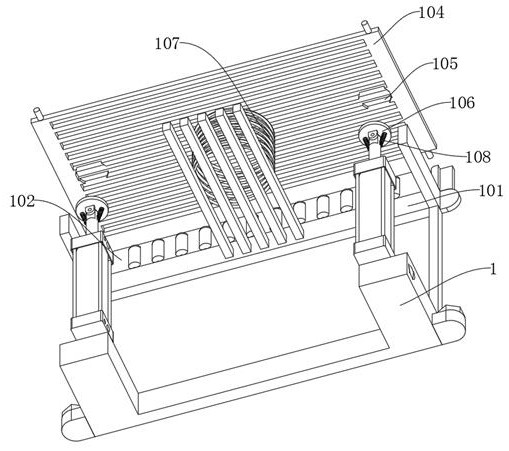

[0042] Example: Please refer to Figure 1 to Figure 8 :

[0043] The present invention proposes a workpiece unloading device for tricycle accessories processing semi-automatic lathes, including: a main body 1, which is installed on the semi-automatic lathe body 4 through a threaded rod, and three hydraulic cylinders are installed on the top of the main body 1, and the side of the main body 1 is provided with threaded holes, and the top plate 101 on the top of the main body 1 and the side of the guide plate 102 are installed with side plates 2; The top of the cylinder; the slideway 3, the slideway 3 is an inclined structure, and the top of the slideway 3 is installed on the two ends of the guide plate 102 through the rotating shaft, and the workpiece processed by the lathe is pushed to the supporting plate 104 by the pulley inside the horizontal plate 206 , and slide down through the slideway 3 into the material storage box 304 for storage.

[0044] Furthermore, according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com