Safety helmet assembling equipment and assembling method thereof

A technology for assembling equipment and assembling methods, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as low assembly efficiency, large labor consumption, and difficulty in meeting, so as to reduce labor consumption, ensure qualified rate, and ensure The effect of assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

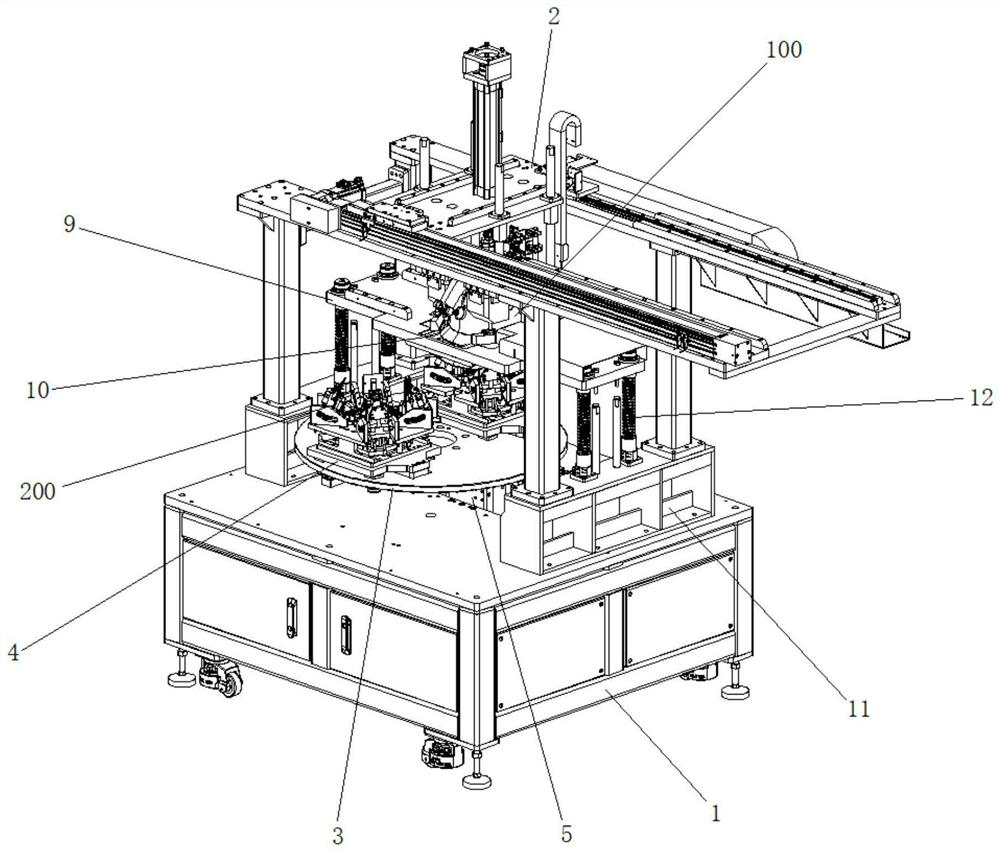

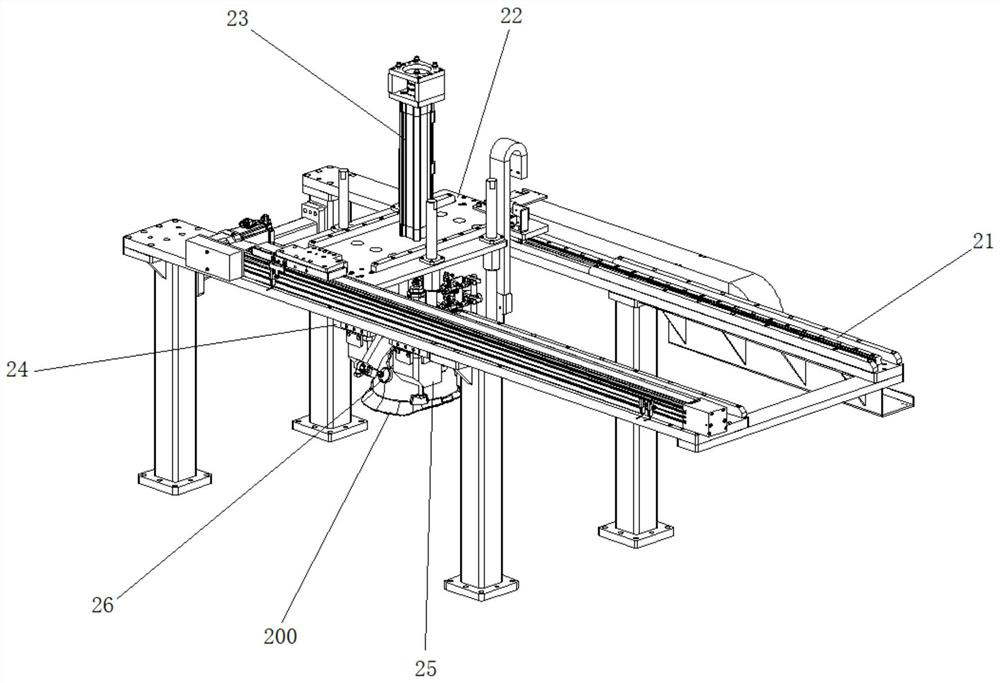

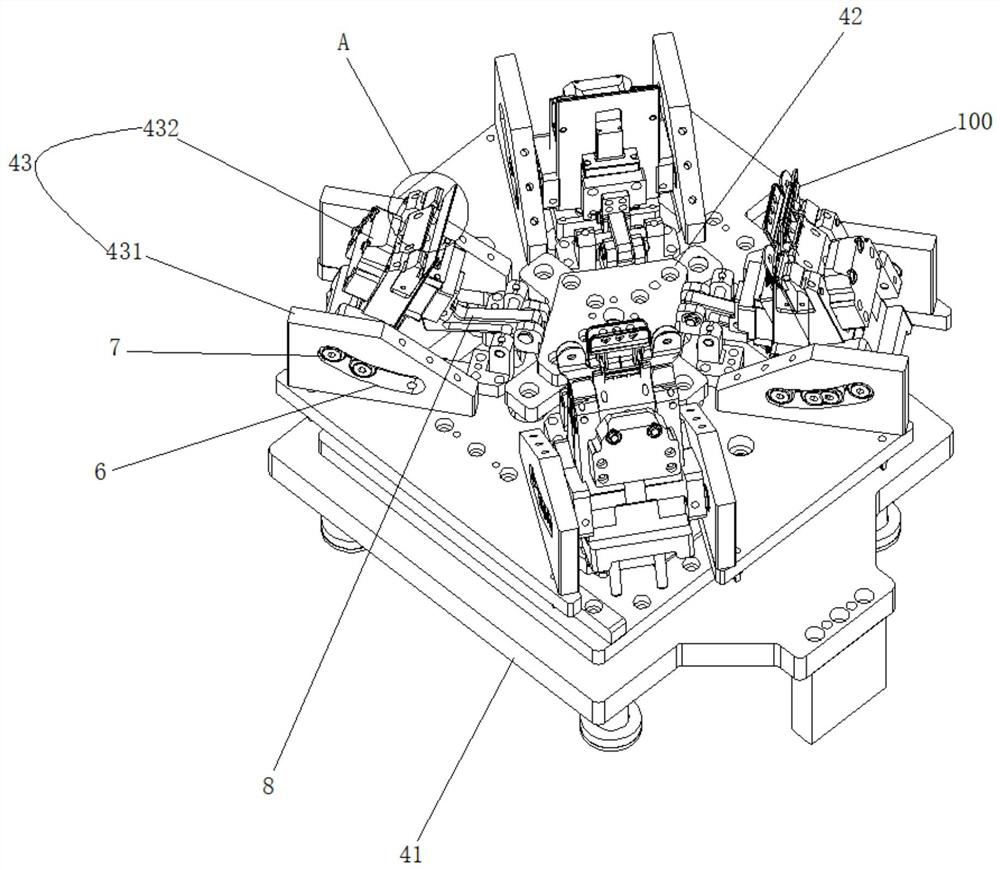

[0034] Such as figure 1 As shown, a safety helmet assembly equipment, the headliner 100 is loaded into the helmet shell 200 of the safety helmet, including a frame 1, a feeding assembly 2 for loading the cap shell 200, and an assembly turntable located on the frame 1 3 and an assembly component 4 for press-fitting the cap liner 100.

[0035] combine figure 1 and Figure 5 As shown, the frame 1 is provided with a jacking assembly 5, the jacking assembly 5 lifts the assembly assembly 4, and presses the cap liner 100 into the cap shell 200. The jacking assembly 5 includes a jacking module 51, a jacking The jacking platform 52 that moves in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com