Printer internal ink conveying pipe auxiliary device with automatic heating and anti-blocking functions

A technology of automatic heating and auxiliary devices, which is applied in the direction of mixers, printing and mixers with rotating stirring devices, which can solve the problems of no anti-blocking devices, lack of automatic heating devices for ink delivery tubes, etc., and achieve the effect of avoiding flow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

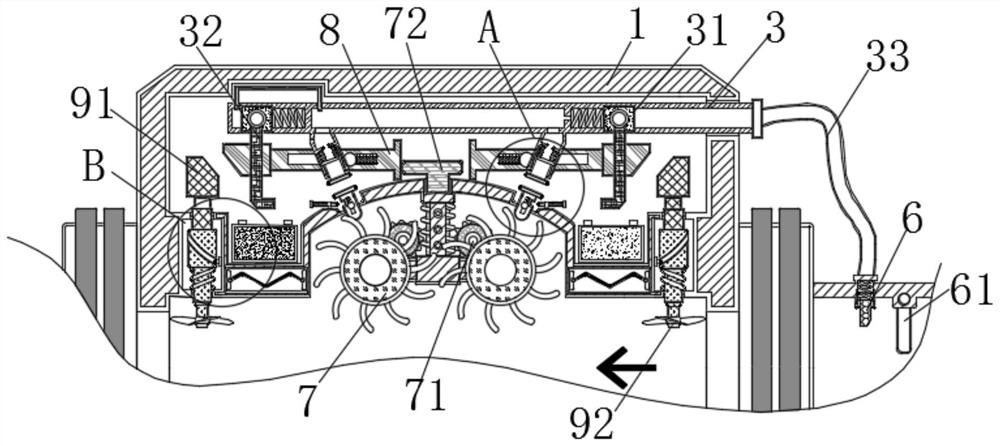

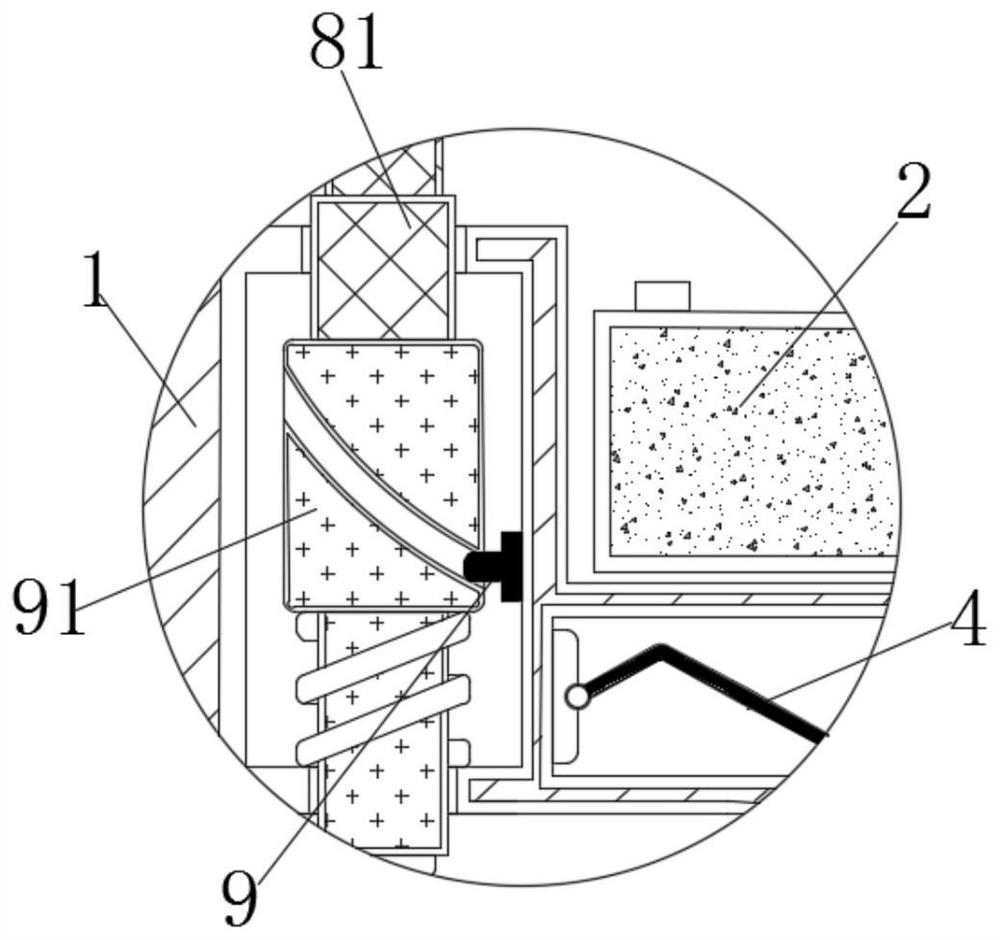

[0024] see Figure 1-2 , an automatic heating and anti-blocking auxiliary device for ink delivery tubes inside the printer, including a casing 1 and a power supply 2, a support mechanism 3 is fixedly connected to the upper part of the casing 1, and a slider 31 is slidably connected to the inside of the support mechanism 3. The slider 31 A fixed rod 32 is fixedly connected to the surface, an air pipe 33 is fixedly connected to the right side of the support mechanism 3 , and a heating mechanism 4 is arranged at the bottom of the power supply 2 .

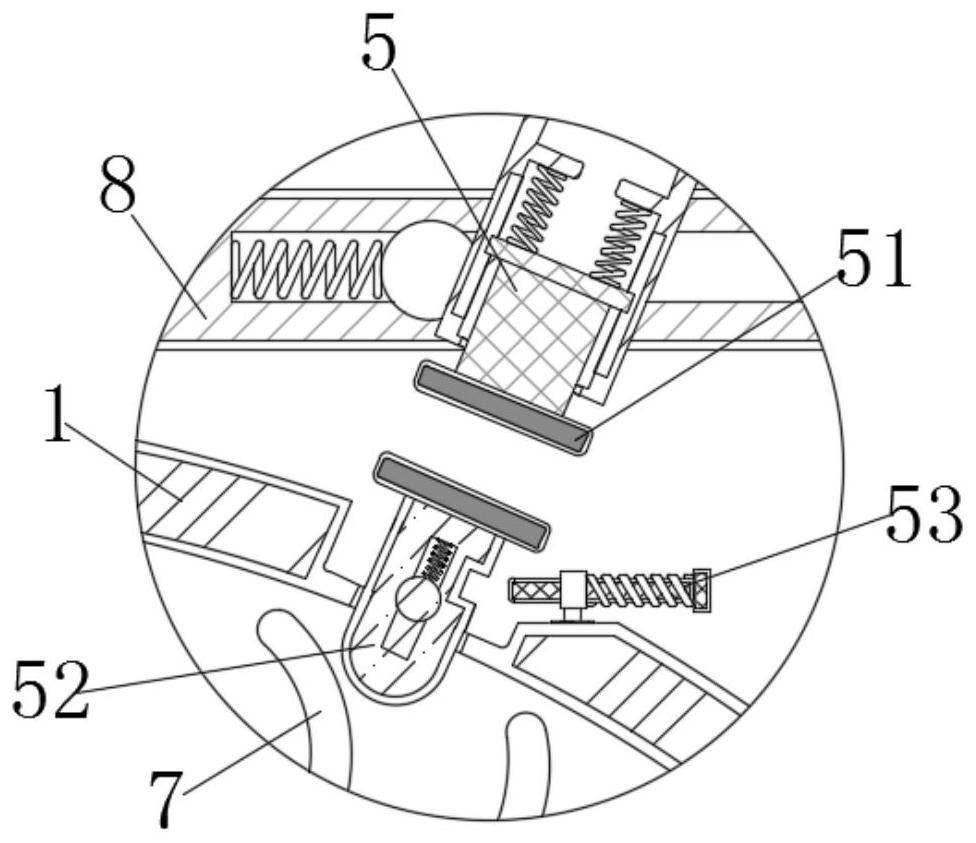

[0025] Further, the end of the fixed rod 32 away from the inner wall of the casing 1 is provided with a first push block 5, the bottom end of the first push block 5 is fixedly connected with a contact 51, and the bottom of the contact 51 is provided with a second push block 52, the second push block 5 A notch is provided on the surface of the block 52, and the second push block 52 is provided with a blocking rod 53 near one end of the ...

Embodiment 2

[0029] see Figure 3-4 , an automatic heating and anti-blocking auxiliary device for ink delivery tubes inside the printer, including a casing 1 and a power supply 2, a support mechanism 3 is fixedly connected to the upper part of the casing 1, and a slider 31 is slidably connected to the inside of the support mechanism 3. The slider 31 A fixed rod 32 is fixedly connected to the surface, an air pipe 33 is fixedly connected to the right side of the support mechanism 3 , and a heating mechanism 4 is arranged at the bottom of the power supply 2 .

[0030] Further, the bottom of the second push block 52 is provided with a roller 7, and the back of the roller 7 is provided with a runner 71, and the tooth grooves on the surface of the runner 71 match the tooth grooves on the back of the roller 7, and the runner 71 is arranged at an end far away from the roller 7. There is a movable rod 72, the ink drives the roller 7 to rotate, so that the roller 7 drives the runner 71 to rotate thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com