Wear-resistant sealing structure of servo hydraulic cylinder

A servo hydraulic cylinder and sealing structure technology, applied in the field of hydraulic cylinders, can solve the problems of the protection structure and method without the wear-resistant sealing effect of the piston position, and the reduction of the sealing effect of the piston-piston position, etc. Wear-resistant use effect, improve the effect of sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

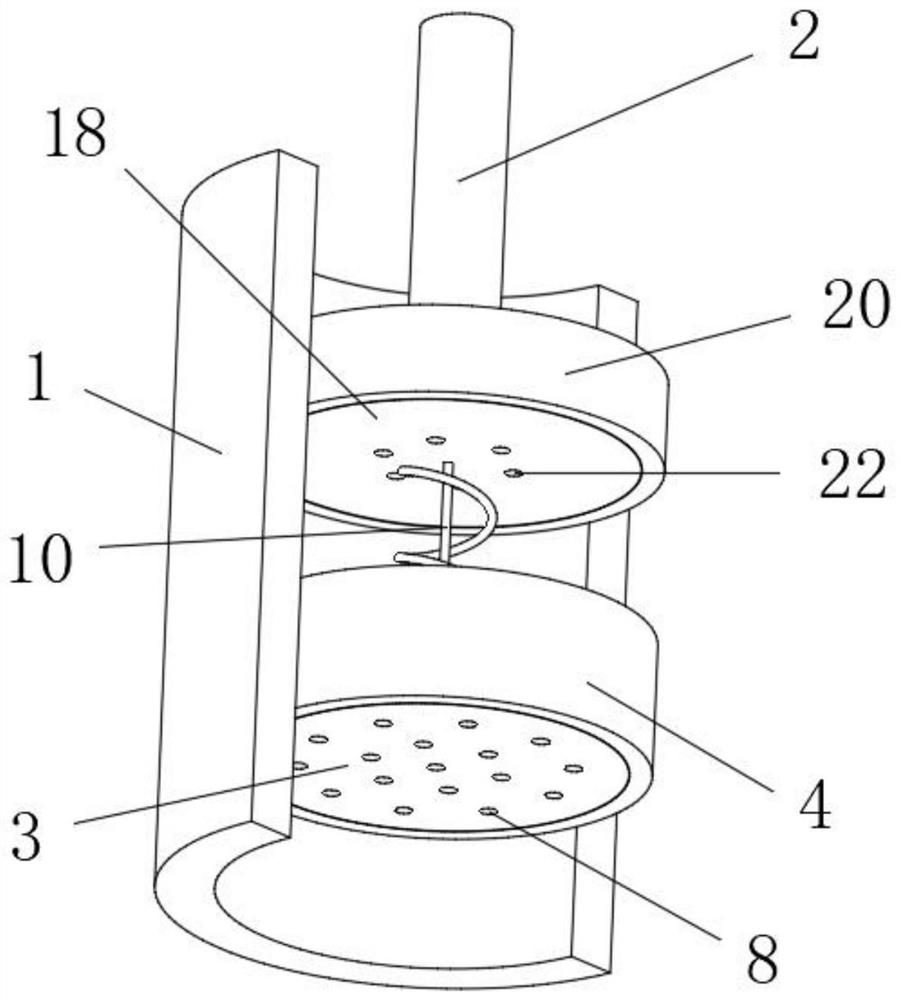

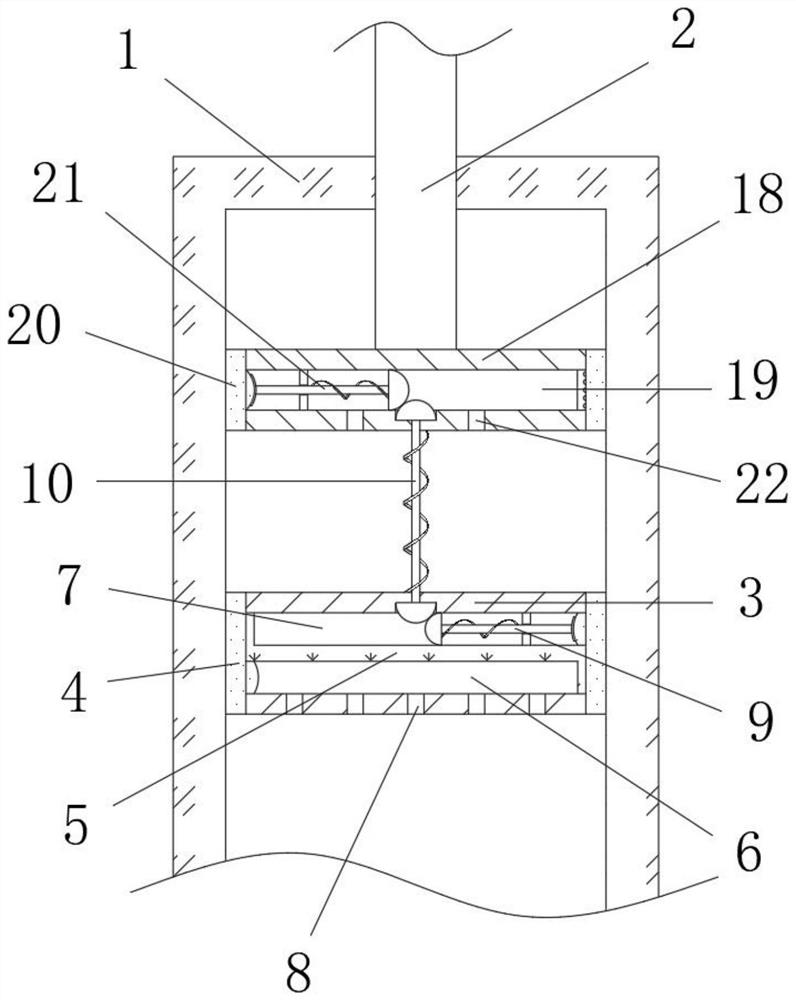

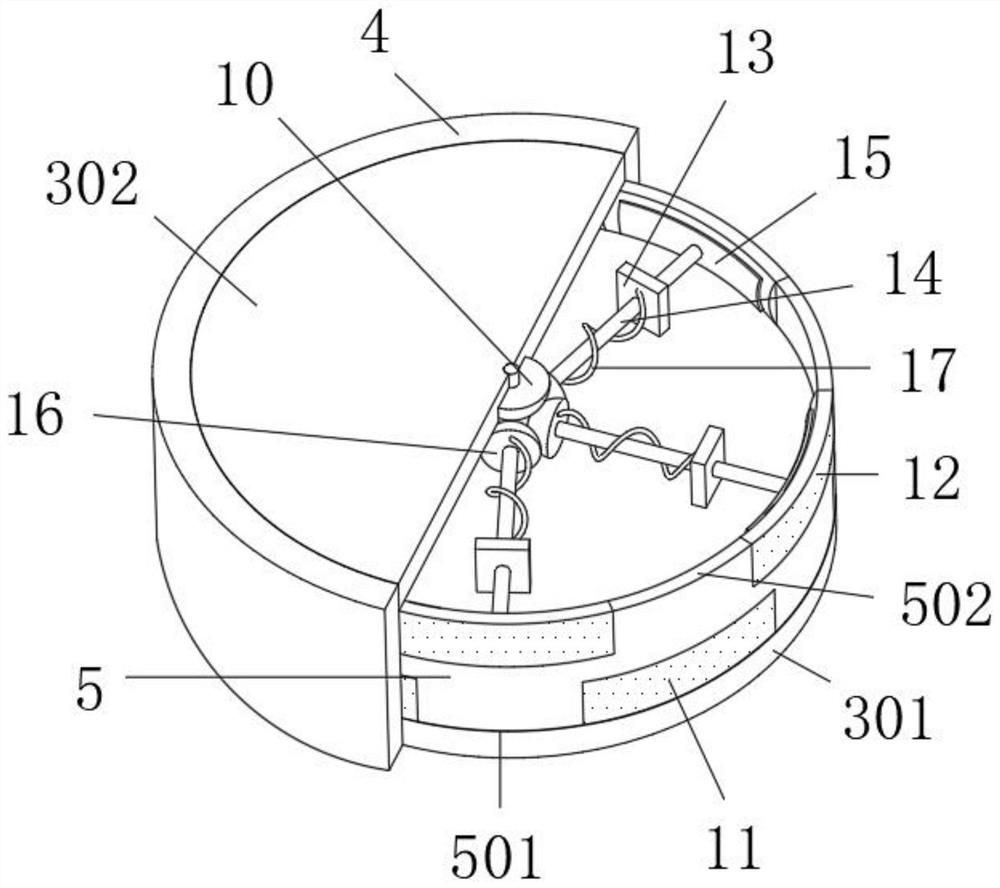

[0028] Refer Figure 1 - Figure 4A servo hydraulic cylinder wear-resistant sealing structure, including the cylinder 1 and the telescopic rod 2, and the bottom end of the telescoping rod 2 is fixedly connected to the inner wall of the cylinder 1, and the outer wall sleeve of the piston member 3 is fixed. The first rubber sleeve 4 of the case is provided with a hydraulic chamber 6 in the bottom of the piston member 3, and the bottom of the hydraulic chamber 6 is in communication with the bottom of the cylinder 1, and the liquid is injected into the liquid and the pressing of the piston member 3 is telescopically. The liquid and the air pressure will enter the hydraulic chamber 6 and extruded the bottom of the inner wall of the first rubber sleeve 4, and the top portion of the piston member 3 is provided with an extruded chamber 7, and the position corresponding to the first rubber sleeve 4 is provided in the extruder 7. Mechanical buffer structure, the piston frame 3 is extruded dur...

Embodiment 2

[0033] Example 2 includes all structures and methods of Example 1, reference Figure 1 - Figure 6 A servo hydraulic cylinder wear-resistant sealing structure, further comprising, the bottom end of the telescoping rod 2 fixes a fixing member 18, and the outer wall of the fixing member 18 has a second rubber sleeve 20 of the annular structure, the bottom of the fixture 18 A connecting buffer mechanism 10 is connected between the intermediate position of the piston member 3, and the inside of the fixing member 18 is opened, and a plurality of horizontal placed second extrudation mechanisms 21, the second extrusion 19 are provided in the connection chamber 19. The mechanism 21 is adapted to the connection buffer mechanism 10, and the second extrusion mechanism 21 and the first extrusion mechanism 9 are arranged to be spaced apart from the circumferential surface, thereby constituting a fixed plug and a moving plug through the fixing member 18 and the piston member 3. To achieve the buf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com