Steel shell button cell and preparation method thereof

A technology of button battery and steel case, which is applied in the field of steel case button battery and its preparation, which can solve the problems of electrolyte residue, discoloration of weld seam surface, weld voids and other problems, so as to improve sealing performance and laser welding Stability, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

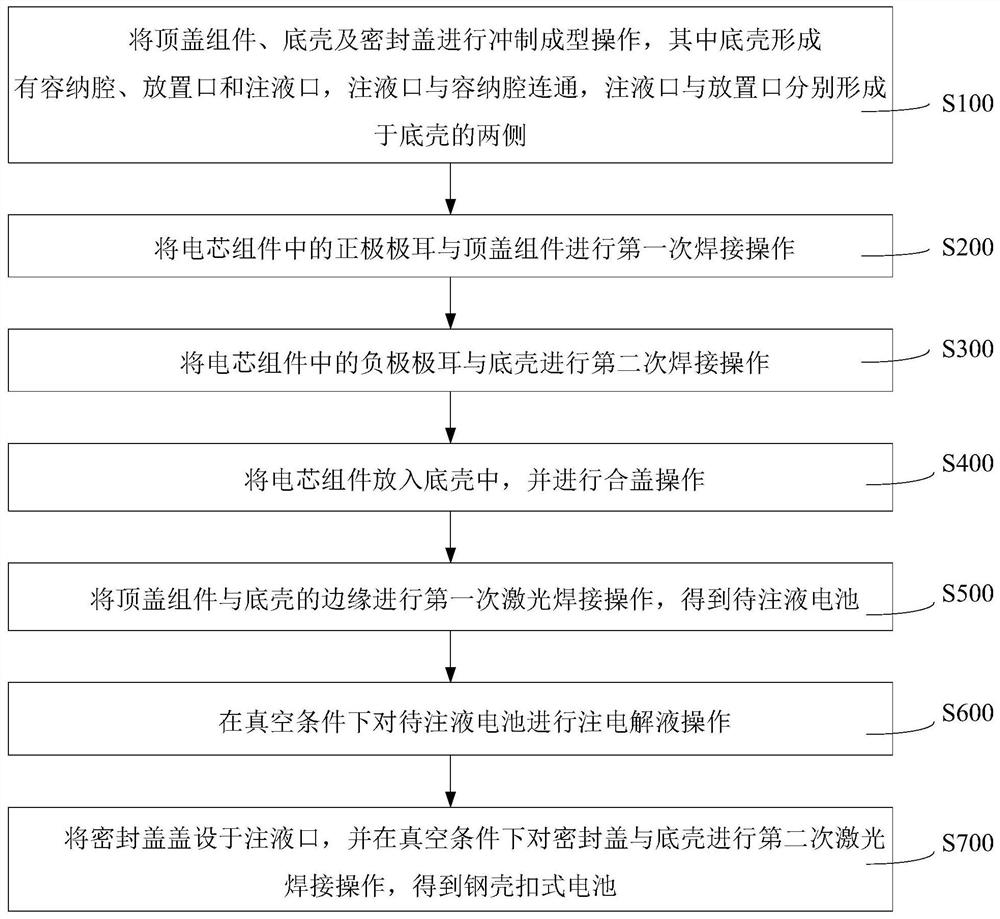

preparation example Construction

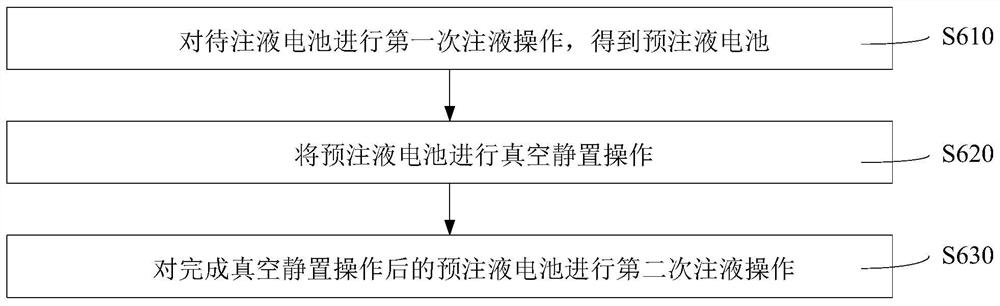

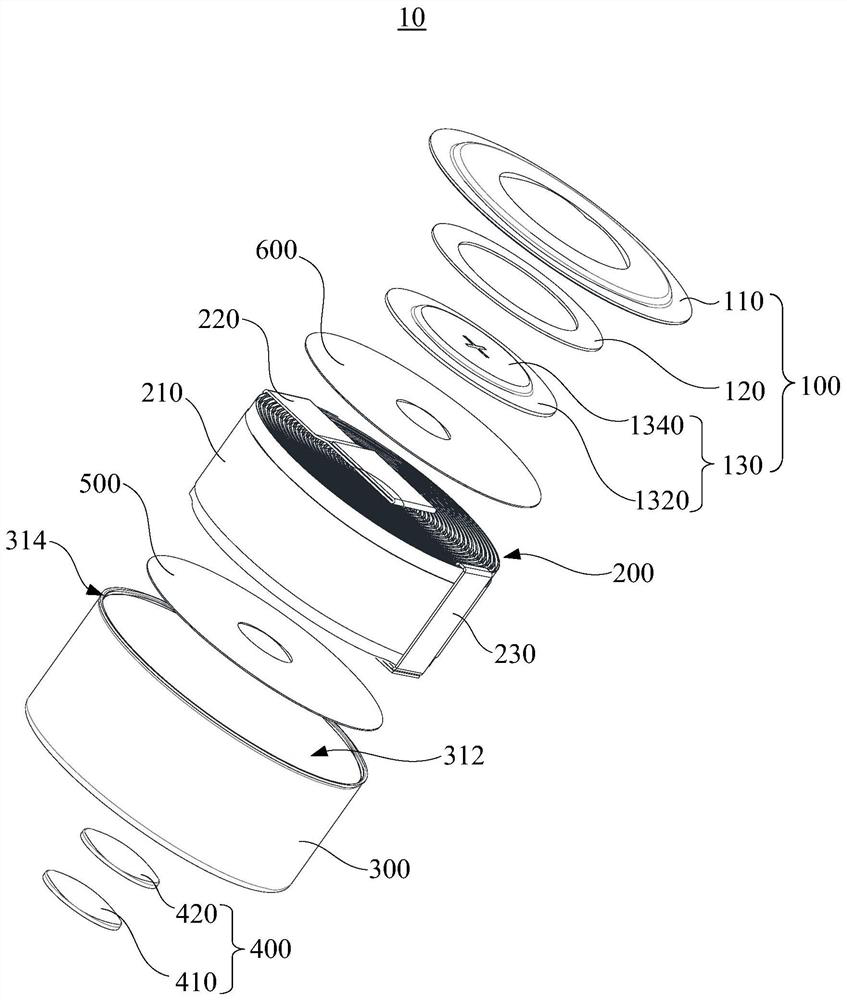

[0047]The present application provides a method for preparing a steel button cell. Steel coin cell prepared above method comprises the steps of: a header assembly, for punching the sealing cap and the bottom shell molding operation, wherein the bottom cover is formed with a receiving cavity, placing the liquid inlet port and the injection port in communication with said receiving chamber, said injection port and the liquid is placed on both sides of each opening formed in the bottom cover; the positive electrode cell tab assembly and the cap assembly is first welding operation; the cell assembly and said pan negative electrode tab a second welding operation; the cell assembly is placed in the bottom shell, and closing operation of the cover; and the cap assembly the first edge of the bottom case is a laser welding operation, the injection cell to be obtained; injection-electrolyte liquid injection operation of the battery to be under vacuum; sealing cap pouring port provided in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com