Thermal power plant electrical automation anti-electromagnetic interference control cabinet

An electrical automation and anti-electromagnetic interference technology, which is applied in the direction of electrical equipment shells/cabinets/drawers, electrical components, magnetic field/electric field shielding, etc. problem, to achieve the effect of reducing electromagnetic interference, enhancing anti-electromagnetic interference ability, and enhancing regularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

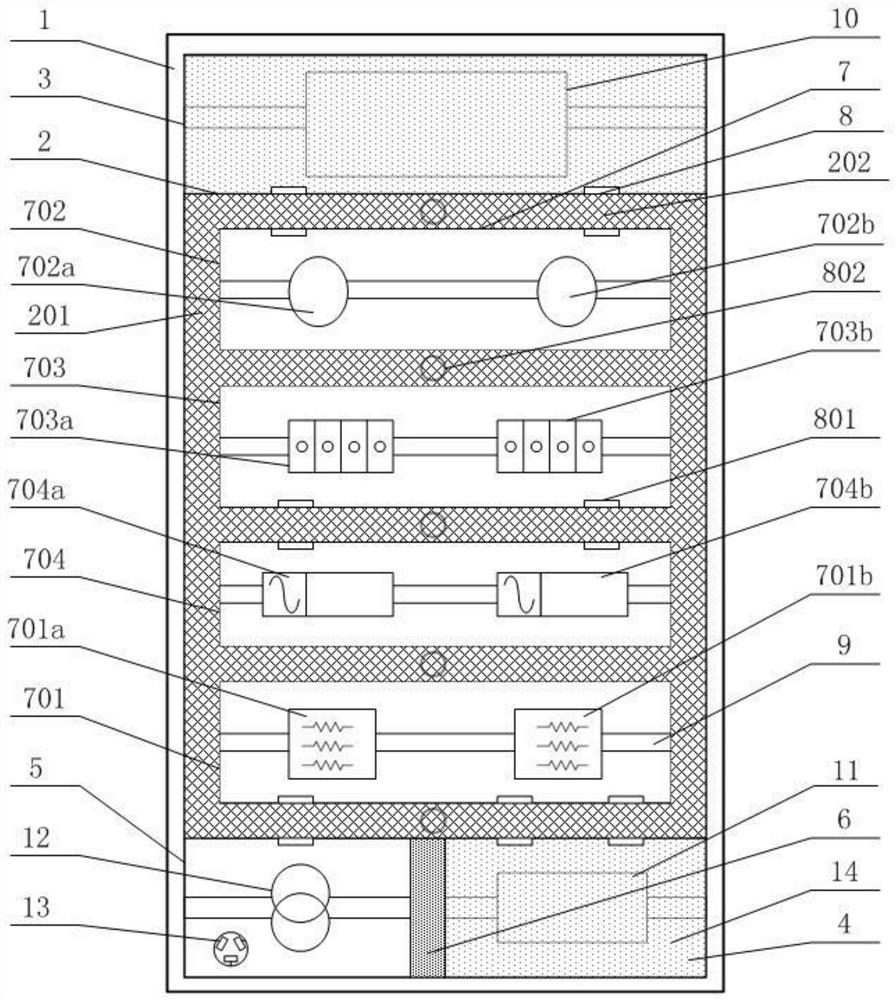

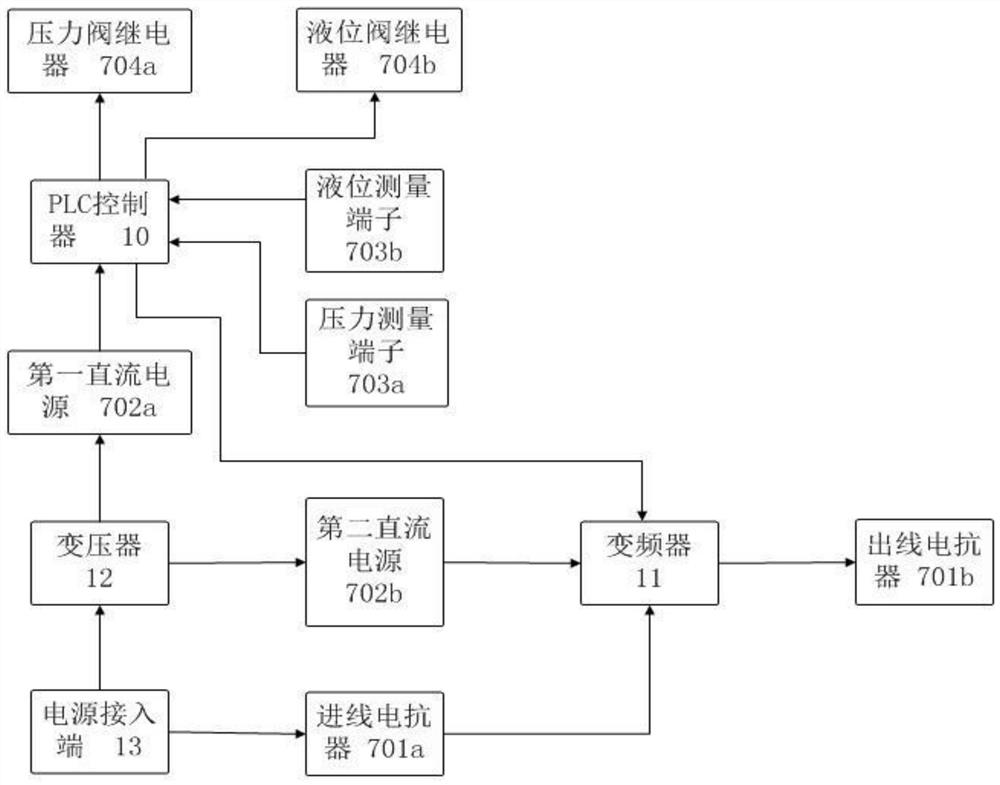

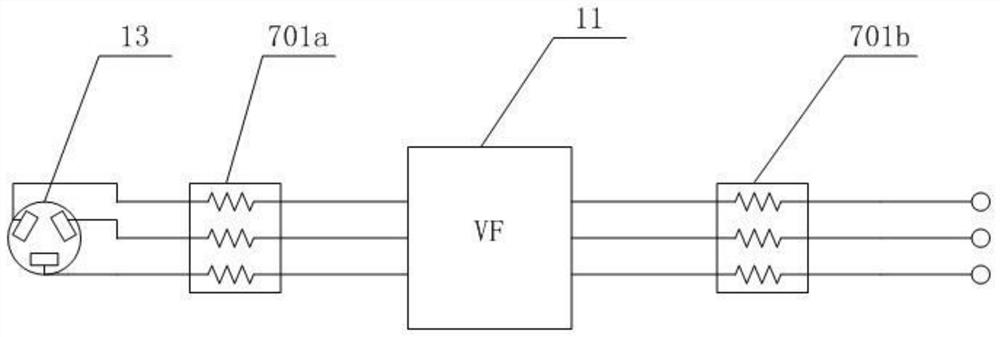

[0031] Such as Figure 1 to Figure 3 As shown, this embodiment provides a thermal power plant electrical automation anti-electromagnetic interference control cabinet, including a stainless steel cabinet body 1, a wiring trough device 2, a wiring hole 8, a PLC controller 10, a frequency converter 11, a transformer 12, a power connector The input terminal 13, wherein, the PLC controller 10 is connected with the frequency converter 11 and the transformer 12 respectively, the power input terminal 13 is connected with the frequency converter 11 and the transformer 12 respectively, and the stainless steel cabinet body 1 is divided into an area divided by the wiring trough device 2 It includes a PLC controller placement area 3 for arranging a PLC controller 10 located above the wiring trough device 2, a frequency converter placement area 4 for arranging a frequency converter 11 and a transformer 12 located below the wiring trough device 2 And the transformer placement area 5 of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com