Conveyor rack sheet metal part welding jig

A welding jig and sheet metal technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low assembly efficiency and poor accuracy, improve assembly efficiency and accuracy, and expand the scope of application , Improve the effect of assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

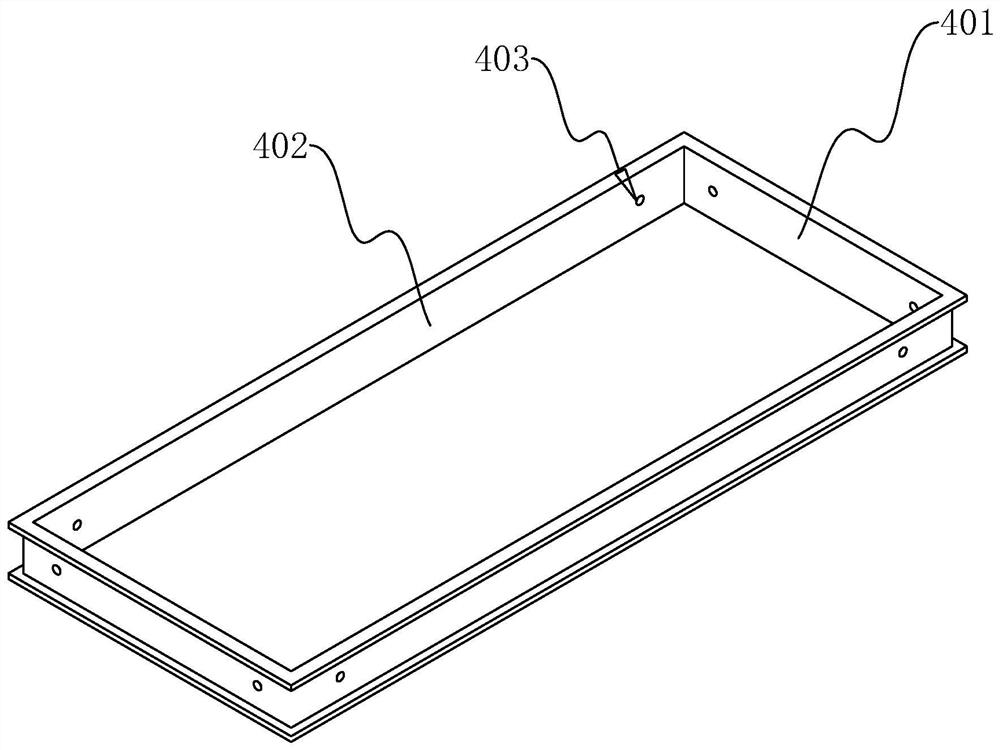

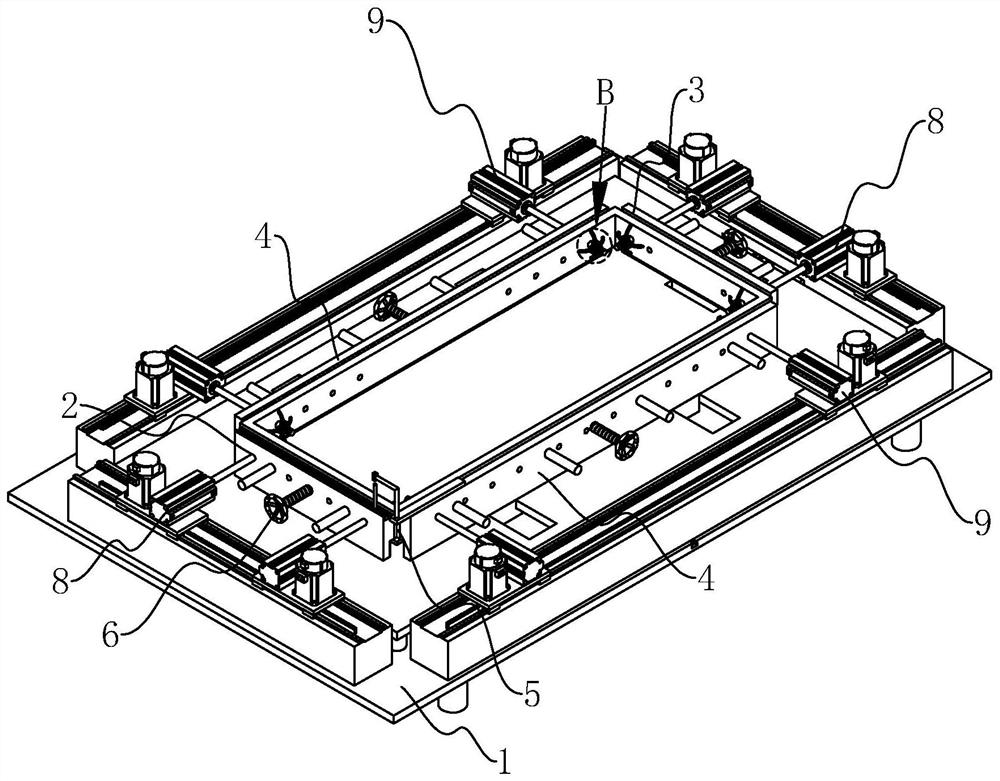

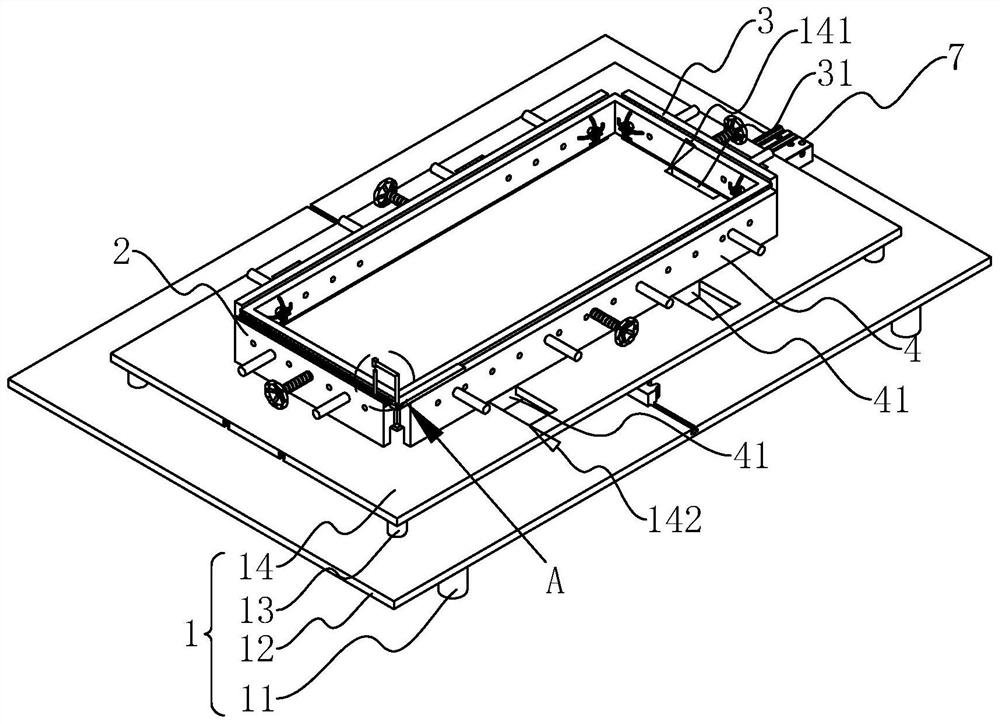

[0042] The following is attached Figure 2-9 The application is described in further detail.

[0043] The embodiment of the present application discloses a welding jig for sheet metal parts of a conveyor frame. refer to figure 2 and image 3 The conveyor frame sheet metal parts welding fixture includes a clamp body 1, including a plurality of first support legs 11, a first mounting plate 12 welded to the top ends of the plurality of first support legs 11, and welded to the first mounting plate 12. The second supporting legs 13 on the surface and the second mounting plate 14 welded to the tops of the multiple second supporting legs 13, the first mounting plate 12 and the second mounting plate 14 are both in the shape of a cuboid, and the length direction and the width direction are consistent.

[0044] refer to figure 2 and image 3 The positioning seat 2 and the first movable seat 3 are relatively arranged on the second mounting plate 14 , and the length direction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com