Inflatable water-jet propeller

A water jet propulsion, inflatable technology, applied in the direction of ship propulsion, propulsion components, ship components, etc., to achieve the effects of suppressing collapse strength, improving acoustic stealth performance, and improving cavitation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

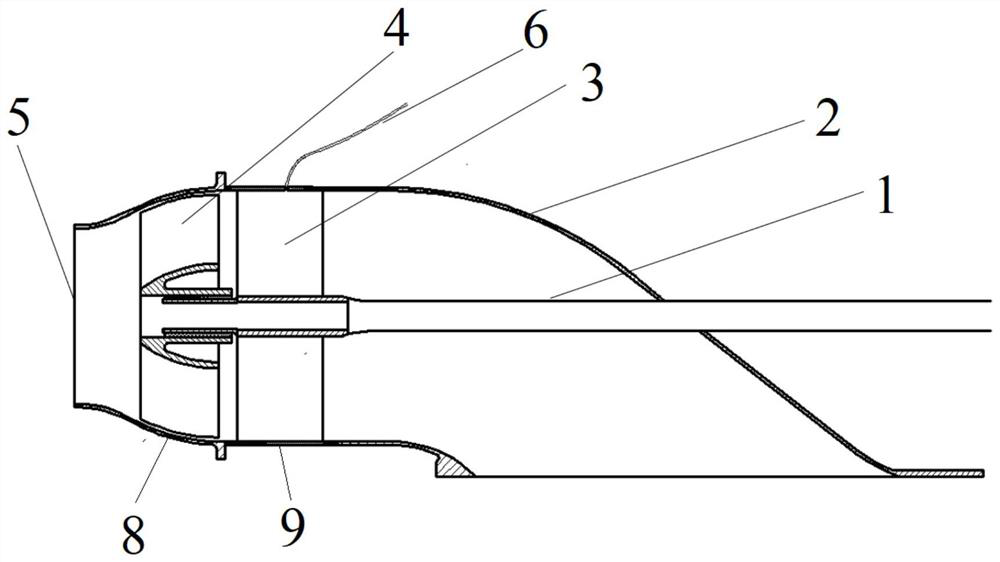

[0028] The invention provides an inflatable water jet propeller, such as figure 1 As shown, it includes shaft 1, inlet channel 2, guide vane 3, impeller 4, nozzle 5, air supply pipe 6, pump casing, one end of the pump casing is provided with nozzle 5, and the pump casing is provided with impeller 4 and inlet flow 2, the impeller 4 is set between the nozzle 5 and the inlet flow channel 2, and the impeller 4 is fixed on the shaft 1 that can drive the impeller 4 to rotate. Between Road 2. The pump casing includes an inlet channel 2, a guide vane housing 9 and an impeller housing 8. One end of the inlet channel 2 is connected to one end of the impeller housing 8 through the guide vane housing 9, and the other end of the impeller housing 8 is provided with a nozzle. 5. The guide vane housing 9 is provided with a guide vane 3, the guide vane 3 is fixed on the shaft sleeve, and the shaft sleeve is sleeved on the shaft 1, so that the shaft 1 can rotate in the shaft sleeve. Guide van...

Embodiment 2

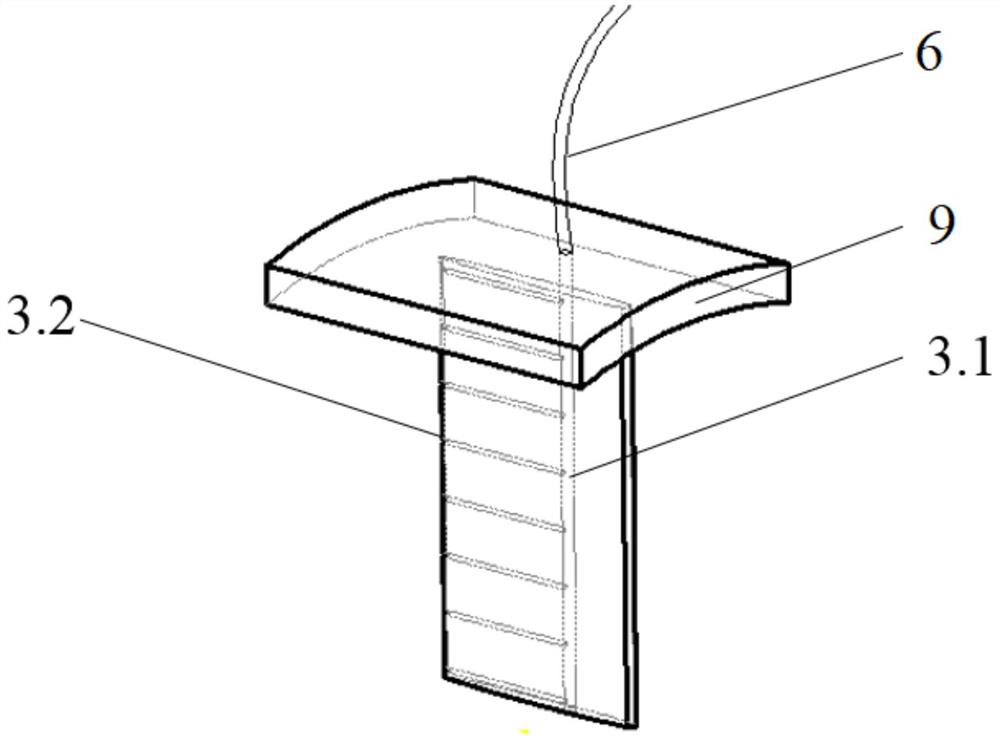

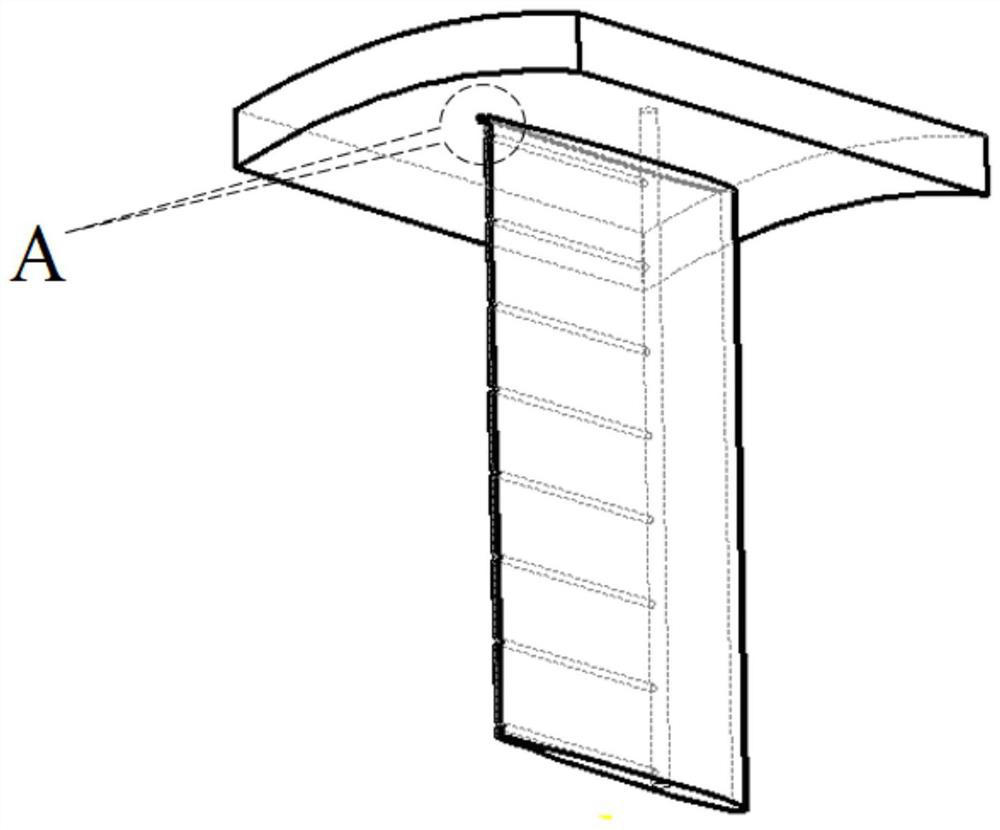

[0036] In this example, if Figure 5 As shown, the internal air supply pipeline 3.1 includes a plurality of individual pipelines, one end of each individual pipeline is respectively connected to the air supply pipeline 6, and the other end of each individual pipeline is respectively connected to an air injection port 3.2. Each pipeline can be controlled independently.

[0037] Others are the same as in Example 1.

Embodiment 3

[0039] In this example, if Image 6 As shown, the air charging hole is arranged at the entrance of the inlet flow channel 2, that is, the inflatable device is set at the entrance of the inlet flow channel 2, the connection position of the air supply pipeline 6 and the pump casing is located at the entrance of the inlet flow channel 2, and the air supply pipeline 6 One end passes through the pump casing at the inlet position of the inlet channel 2 and is connected with the inflation device. For some water jet propellers, the cavitation primary position is near the entrance of the inlet flow channel 2, that is, the inner wall of the inlet flow channel 2 near the position of the air supply pipeline 6 in the figure. At this time, the gas supply pipeline 6 can be arranged at the inlet of the inlet flow channel 2, and the generation of cavitation can be suppressed by means of inflation.

[0040] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com