Yarn guiding equipment with carding function for textile cotton yarn feeding

A cotton yarn and textile technology, applied in the field of wire equipment, can solve the problems of incomplete surface treatment of textile cotton yarn, and achieve the effect of ensuring comprehensiveness and stability and facilitating processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

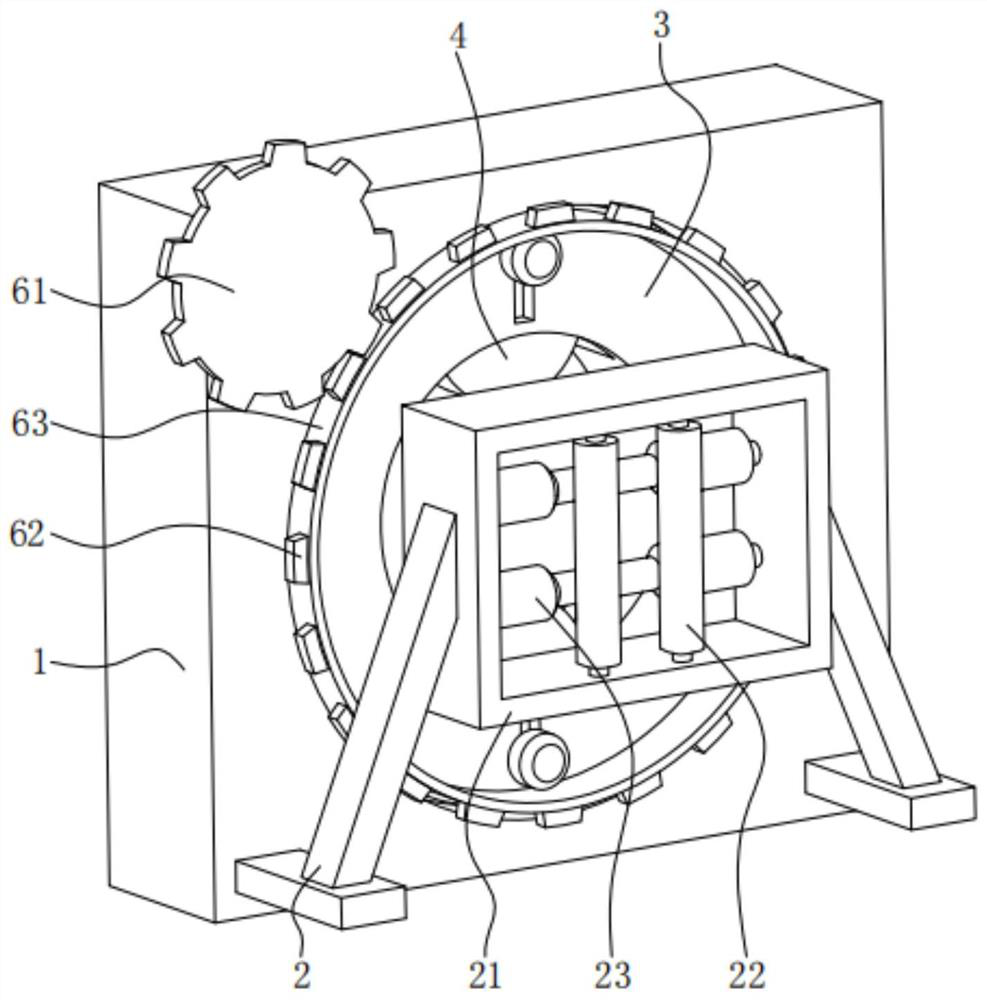

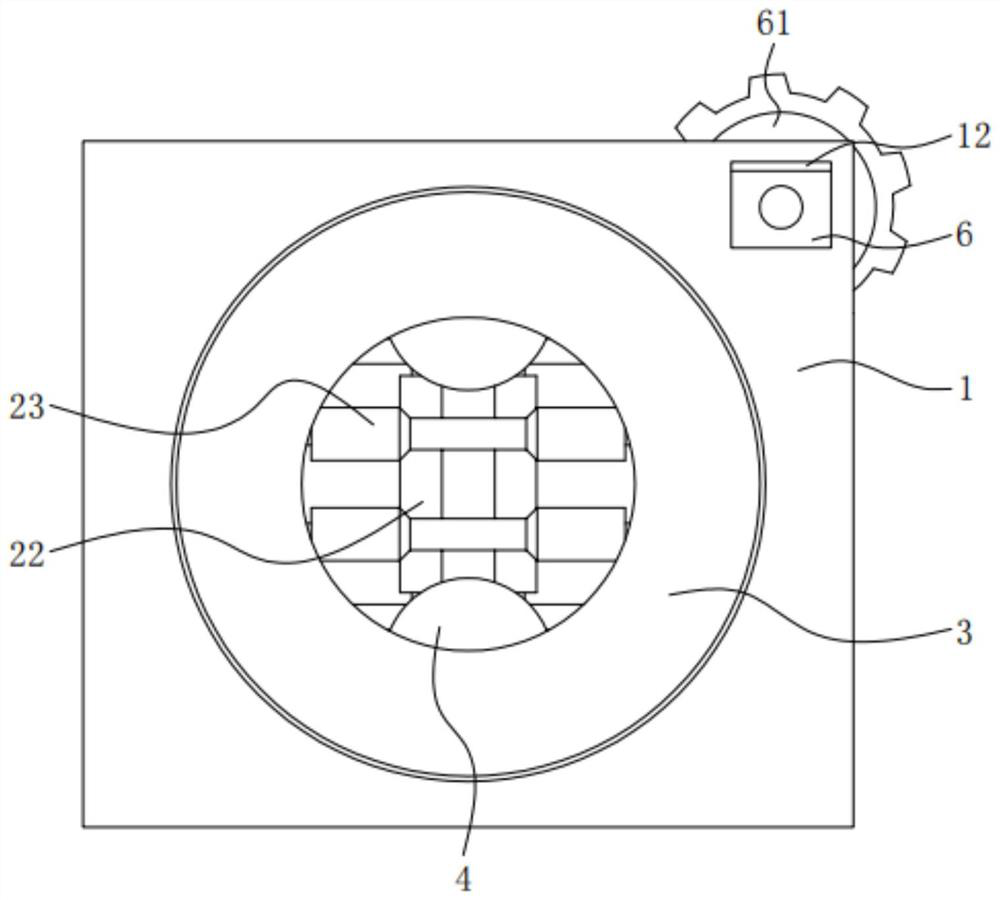

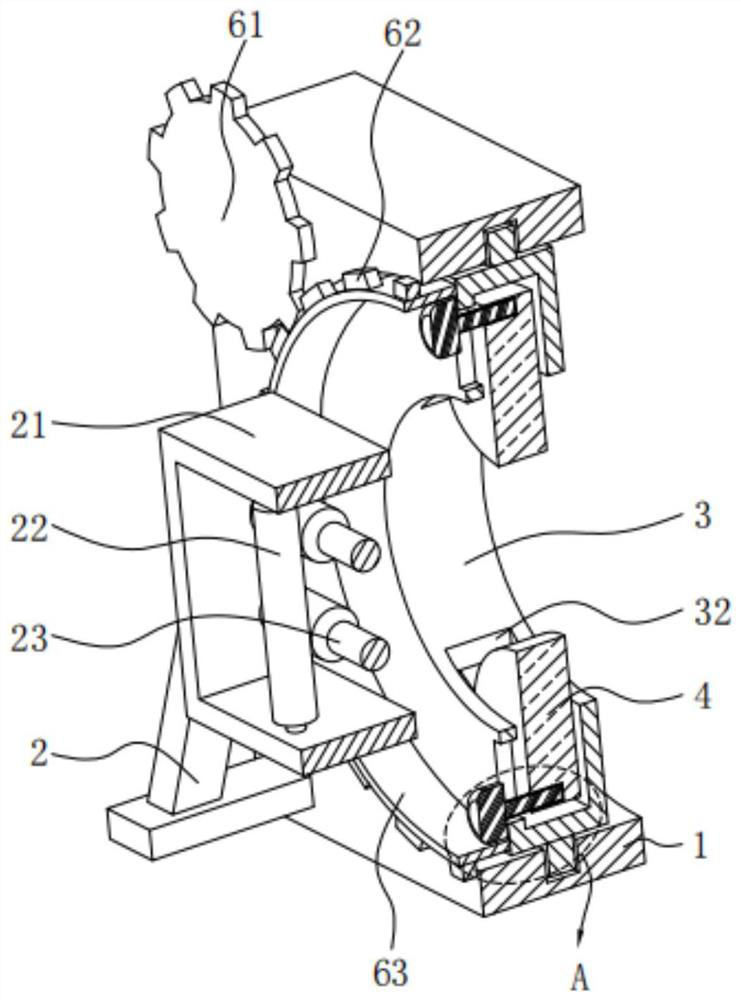

[0038] A kind of wire equipment with carding function for textile cotton yarn feeding comprises: a mounting frame 1, which is provided with a rotating groove 11 and a mounting groove 12; a connecting frame 2, one side of which is fixedly installed on the On the surface of the mounting frame 1, the inner side of the connecting frame 2 is fixedly connected with a fixed frame 21, and the inner side of the fixed frame 21 is respectively provided with a first conveying roller 22 and a second conveying roller 23; the rotating disk 3, the The surface of the rotating disk 3 is movably installed in the inside of the rotating groove 11 by connecting the outer ring 31; the carding disk 4, the carding disk 4 is installed on the surface of the rotating disk 3; the adjusting motor 6, the adjusting motor 6 One side is fixedly connected to the inner surface of the installation groove 12, the output end of the adjustment motor 6 is fixedly connected with a driving gear 61, and the surface of th...

Embodiment 2

[0056] The inner side of the rotating disk 3 is provided with a telescopic groove 32 and a connecting hole 33, and the surface of the carding disk 4 is movably installed in the inside of the telescopic groove 32, and the carding disk 4 is provided with an adjustment groove 41, and the adjustment The inner surface of the groove 41 is threadedly connected with the adjusting screw shaft 5 .

[0057] The fixedly installed carding disc 4 is movably installed on the rotary disc 3, so that the carding disc 4 can be conveniently adjusted on the rotary disc 3 by adjusting the screw shaft 5, so as to facilitate the adjustment of the contact degree between the carding disc 4 and the textile cotton yarn, Thereby, it is convenient to fully comb the surface of the textile cotton yarn, and at the same time, the adjustable carding disc 4 can adjust the number of operations according to the needs of use, so as to meet the different needs of users.

[0058] The interior of the connecting hole 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com