Vertical honeycomb heating body

A technology of heating element and honeycomb, which is applied in the field of stoves, can solve the problems of slow fire response speed of honeycomb body, abnormal combustion of fire holes, and low porosity, so as to improve the reliability of ignition induction, fast fire response speed, and antifouling performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

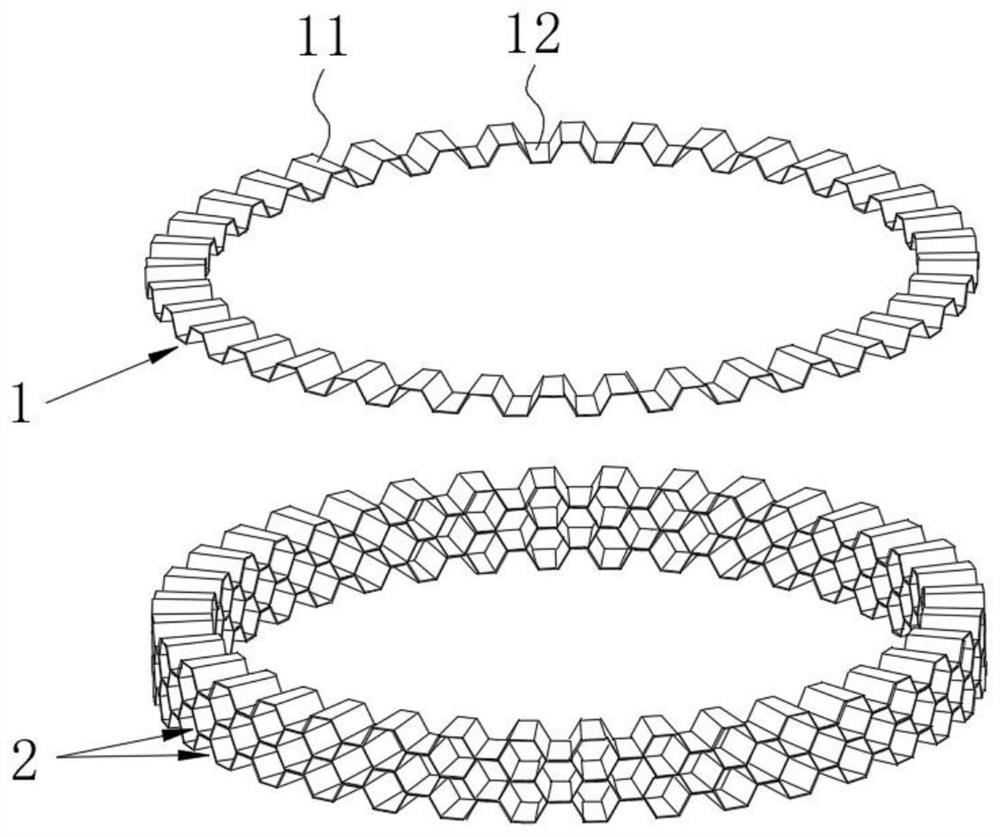

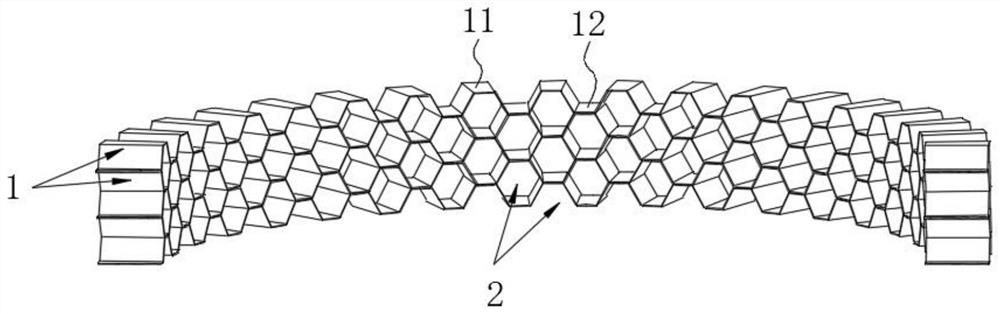

[0034] refer to Figure 1-2 , this embodiment provides a vertical honeycomb heating element, including a plurality of ring-shaped strips 1 stacked one after another in the vertical direction. In this embodiment, adjacent ring-shaped strips 1 are bonded to each other. Fixed connection to improve the overall firmness and reliability of the vertical honeycomb heating element. A plurality of fire holes 2 arranged at intervals along the circumferential direction are formed on the endless strip 1 and / or between adjacent endless strips 1 , and each fire hole 2 is arranged horizontally or obliquely in the vertical direction.

[0035] When the air-fuel mixture burns at the radially inner end of the fire hole 2, the radially inner wall of the vertical honeycomb heating element is the heating surface; when the air-fuel mixture burns at the radially outer end of the fire hole 2, the vertical honeycomb heats up The radially outer wall surface of the body is a heating surface.

[0036] It...

Embodiment 2

[0048] The difference between this embodiment and Embodiment 1 is that it also includes a top plate 3 and a bottom plate 4 arranged side by side at intervals up and down. The bottom plate 4 is connected with the adjacent endless strip material 1 above it. Therefore, by clamping all the annular strips 1 between the top plate 3 and the bottom plate 4, it not only helps to improve the overall rigidity, but also ensures that there is no fire hole on the top surface of the vertical honeycomb heating element, thereby ensuring that there is no overflow or leakage during cooking. Food residues are not easy to fall on the fire hole 2, and the anti-fouling performance is good, and the fire hole 2 is not blocked, which is beneficial to improve the reliability of ignition induction.

[0049] In other embodiments, the top plate 3 or the bottom plate 4 can be omitted. When the top plate 3 is omitted, the fire hole 2 on the top of the heating element has three openings facing upward, radiall...

Embodiment 3

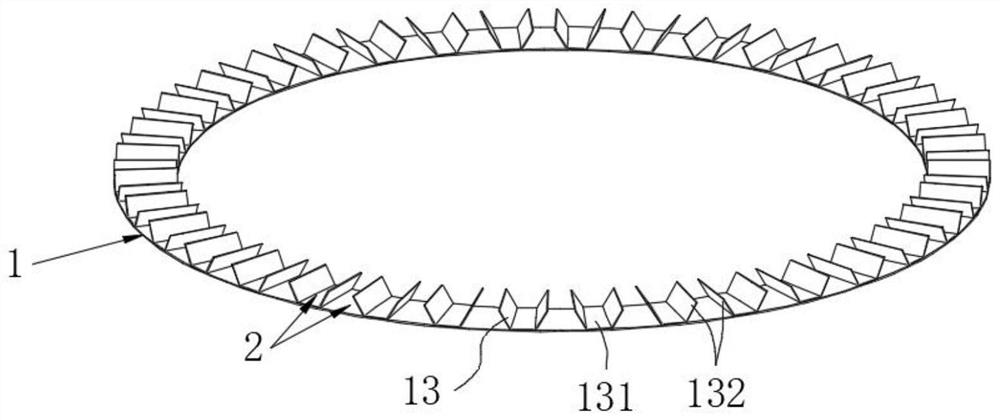

[0051] The difference between this embodiment and embodiment 1 or 2 is that it also includes an annular flat belt 5, adjacent annular belt materials 1 form a pair of belt materials, and an annular flat belt 5 is arranged in at least one pair of belt materials. refer to Figure 5 , in this embodiment, the number of endless flat belts 5 is two, and all the endless belt materials 1 are sorted from bottom to top in the vertical direction, with five layers in total, and the first endless flat belt 5 is arranged on the first Between the layer and the second layer, the second endless flat belt 5 is arranged between the third layer and the fourth layer, and the top surface of each annular flat belt 5 is connected with the endless belt material 1 above it by welding, And the bottom surface of each endless flat belt 5 is connected with the endless belt material 1 below it by welding. Thus, by adding the annular flat belt 5, not only is it beneficial to improve the overall rigidity of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com